Aerogel heat insulation sleeve for battery and preparation method of aerogel heat insulation sleeve

A technology of heat insulation sleeve and airgel, which is applied in the direction of electrical components, battery pack parts, applications, etc., can solve the damage of microfiber sleeve, affect the performance of heat insulation sleeve, and the poor flame retardancy of heat insulation cotton, etc. problem, to achieve the effect of solving the cumbersome winding process, accelerating the growth rate of rubber particles, and uniform molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

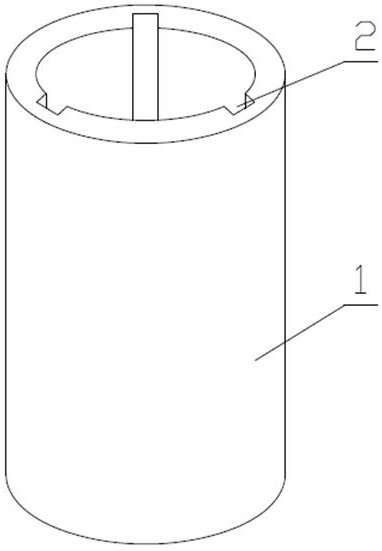

[0020] Such as figure 1 As shown, an airgel heat insulation sleeve for batteries includes a cylindrical sleeve 1 with one end closed, and grooves 2 are opened in the sleeve 1 along the axial direction, and the number of the grooves 2 is 2 , and evenly distributed in the circumferential direction, for placing battery lines.

[0021] In order to ensure the heat insulation performance of the heat insulation sleeve, the wall thickness of the sleeve 1 is 3 mm, the bottom thickness is 8 mm, and the width of the groove 2 is 1.5 mm.

[0022] The preparation method of the airgel heat insulation sleeve for the battery described above comprises the following steps:

[0023] (1) Continuously pump the uniform ultrafine fiber slurry into the hollow special-shaped mold at a rate of 30ml / min, so that the ultrafine fiber slurry flows evenly to all corners of the mold, and at the same time use a vacuum pump for continuous suction. The rate of the aqueous solution is 15ml / min, the solution in ...

Embodiment 2

[0029] Such as figure 1 As shown, an airgel heat insulation sleeve for batteries includes a cylindrical sleeve 1 with one end closed, and a groove 2 is opened in the sleeve 1 along the axial direction, and the number of the groove 2 is 1 , for placement of battery lines.

[0030] In order to ensure the heat insulation performance of the heat insulation sleeve, the wall thickness of the sleeve 1 is 1.5mm, the bottom thickness is 8mm, and the width of the groove 2 is 3mm, which is used to place the battery circuit.

[0031] The preparation method of the airgel heat insulation sleeve for the battery described above comprises the following steps:

[0032] (1) Continuously pump the uniform ultrafine fiber slurry into the hollow special-shaped mold at a rate of 20ml / min, so that the ultrafine fiber slurry flows evenly to all corners of the mold. The rate of the aqueous solution is 10ml / min, the solution in the slurry is extracted, and the fiber is used to build and shape independe...

Embodiment 3

[0038] Such as figure 1 As shown, an airgel heat insulation sleeve for batteries includes a cylindrical sleeve 1 with one end closed, and grooves are opened in the sleeve 1 along the axial direction, and the number of the grooves is 3, and Evenly distributed in the circumferential direction, used to place battery lines.

[0039] In order to ensure the heat insulation performance of the heat insulation sleeve, the wall thickness of the sleeve 1 is 1.5mm, the bottom thickness is 8mm, and the width of the groove 2 is 1mm, which is used to place the battery circuit.

[0040] The preparation method of the airgel heat insulation sleeve for the battery described above comprises the following steps:

[0041] (1) Continuously pump the uniform ultrafine fiber slurry into the hollow special-shaped mold at a rate of 35ml / min, so that the ultrafine fiber slurry flows evenly to all corners of the mold, and at the same time use a vacuum pump for continuous suction. The rate of the aqueous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Bottom thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com