A kind of high reflectance acrylic polyurethane coating composition

An acrylic polyurethane, high reflectivity technology, used in polyurea/polyurethane coatings, reflective/signal coatings, anti-corrosion coatings, etc., can solve the problems of low resin solid content, reduced heat reflection effect, large VOC emissions, etc. High, low VOC release, improve the effect of aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

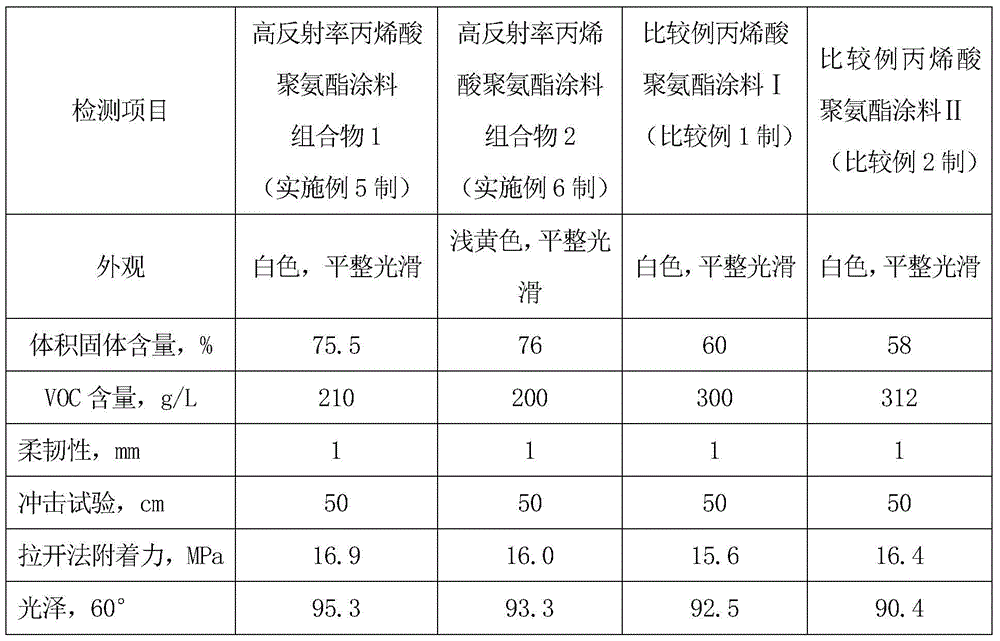

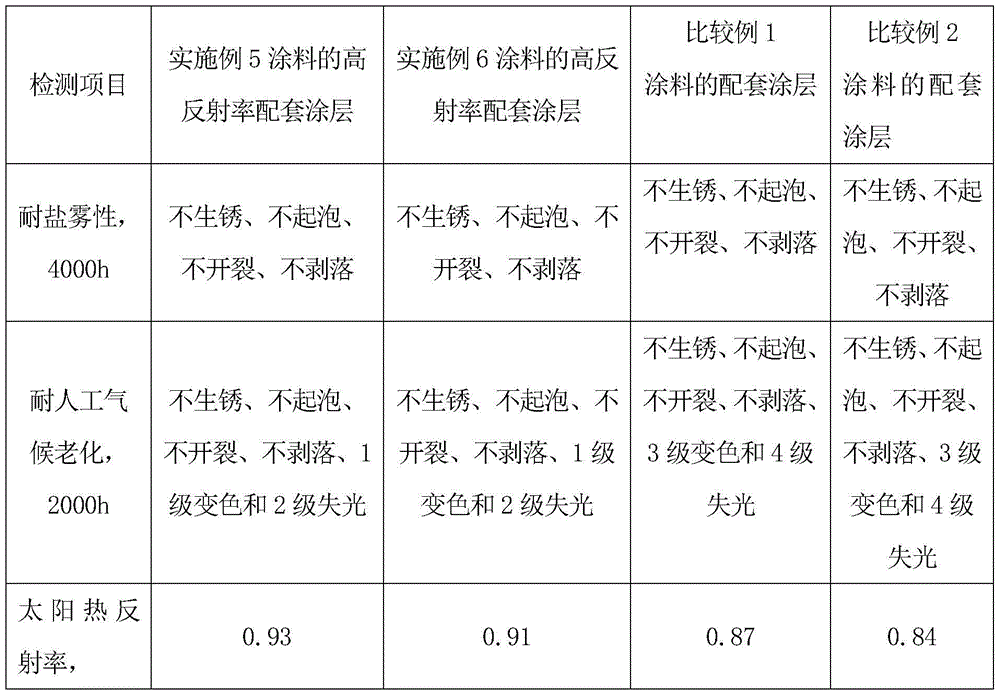

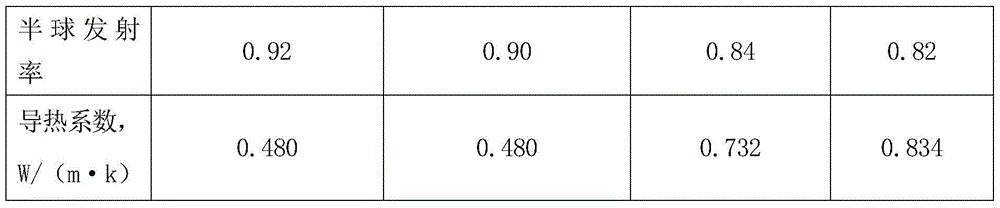

Examples

Embodiment 1

[0025] The preparation modified hydroxyacrylic resin of embodiment 1

[0026] ① Formula

[0027] In the modified hydroxyacrylic resin of every 100 mass parts, 25 mass parts of hydroxyacrylic resin S1196, 75 mass parts of modified resin CTR 6275, wherein: hydroxyacrylic resin S1196 is the product of Nuplex (China) company, and its weight-average molecular weight is 4000-5000, the solid content is 55-60wt%, the hydroxyl content is 2.3-2.6wt%, the viscosity measured by the rotational viscometer is 2400-3800mPa·s; the modified resin CTR 6275 is a product of CNOOC Changzhou Environmental Protection Coatings Co., Ltd., they It is made of functional monomers such as isobornyl methacrylate, cyclohexyl acrylate and glycidyl tert-carbonate as comonomers, with a weight average molecular weight of 2000-2500, a solid content of ≥80wt%, and a hydroxyl content of 4.0- 4.2wt%, the viscosity measured by the rotational viscometer is 2500-3000mPa·s.

[0028] ②Preparation method

[0029] In th...

Embodiment 2

[0030] Embodiment 2 prepares A component 1 (white, pigment base ratio 1.5)

[0031] ① Formula

[0032] In every 100 parts by mass of the A component, 40 parts of modified hydroxyacrylic resins made in Example 1, 39 parts of heat-reflecting pigments (including 26 parts of rutile TiO 2 ALTIRIS 550 and 13 parts rutile TiO 2ALTIRIS 800), 6 parts of airgel SJ1800, 3 parts of additives (including 1 part of dispersant BYK 163, 0.5 parts of defoamer DF-220.5 parts of anti-sagging agent PLUS and 1 part of leveling agent EFKA 3777), 12 parts Organic solvents (including 6 parts xylene and 6 parts butyl acetate).

[0033] ② Preparation method

[0034] In the dispersion tank, add modified hydroxyacrylic resin, organic solvent, dispersant, defoamer, stir evenly, add anti-sag agent PLUS, stir at high speed for 15 minutes, make anti-sag agent PLUS fully wet and disperse, then add Heat-reflecting pigments and aerogels are stirred evenly, then moved into a sand mill, and are ground and disp...

Embodiment 3

[0035] Embodiment 3 prepares A component 2 (light yellow, pigment base ratio 1.5)

[0036] ① Formula

[0037] In every 100 parts by mass of the A component, 40 parts of modified hydroxyacrylic resins made in Example 1, 39 parts of heat-reflecting pigments (including 26 parts of rutile TiO 2 ALTIRIS 550, 13 parts of nickel titanium yellow PY-53), 6 parts of airgel SJ 1800, 3 parts of additives (including 1 part of dispersant BYK 163, 0.5 parts of defoamer DF-22, 0.5 parts of anti-sagging agent PLUS , 1 part of leveling agent EFKA3777), 12 parts of organic solvents (including 6 parts of xylene and 6 parts of butyl acetate).

[0038] ② Preparation method

[0039] In the dispersion tank, add modified hydroxyacrylic resin, organic solvent, dispersant, defoamer, stir evenly, add anti-sag agent PLUS, stir at high speed for 15 minutes, make anti-sag agent PLUS fully wet and disperse, then add Heat reflective pigments and aerogels are stirred evenly, then moved into a sand mill, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com