Preparation method of silk fibroin lyophilized powder

A technology of silk fibroin and preparation process, which is applied in the field of preparation of silk fibroin freeze-dried powder, can solve the problems of limited cosmetic effect and inability of transdermal absorption of large molecular weight silk fibroin, and achieve good cosmetic effect, increased surface area, and convenient The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

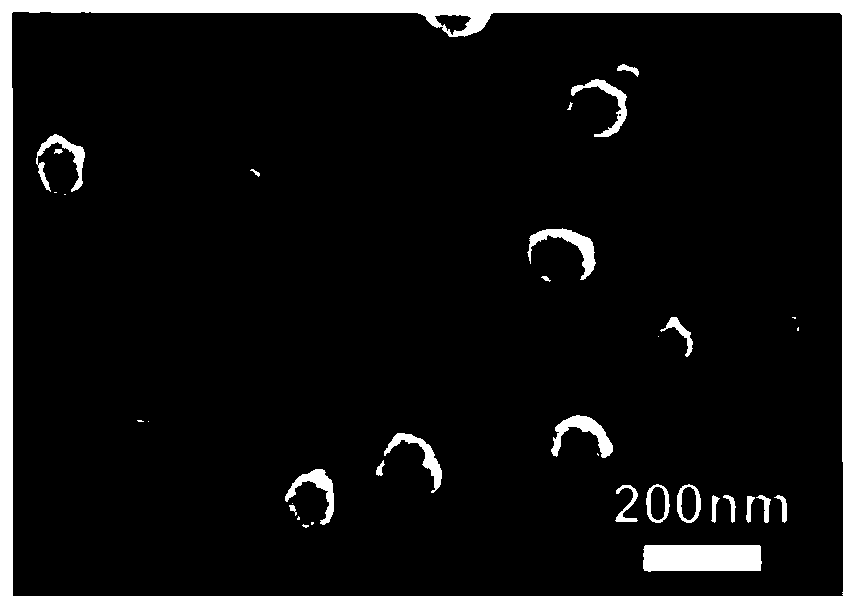

Image

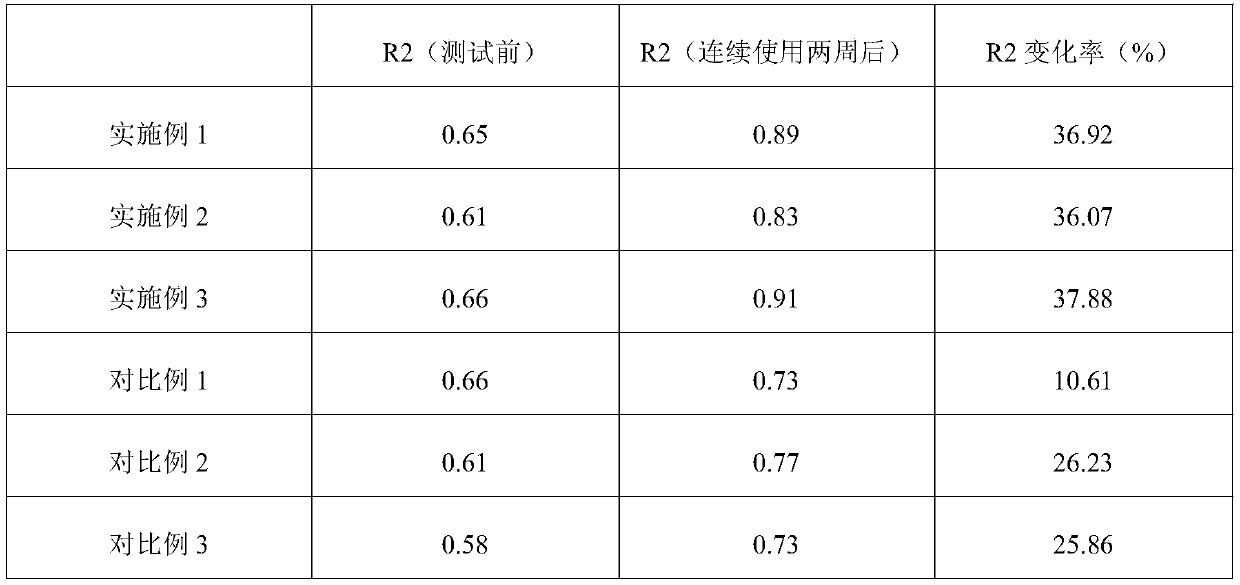

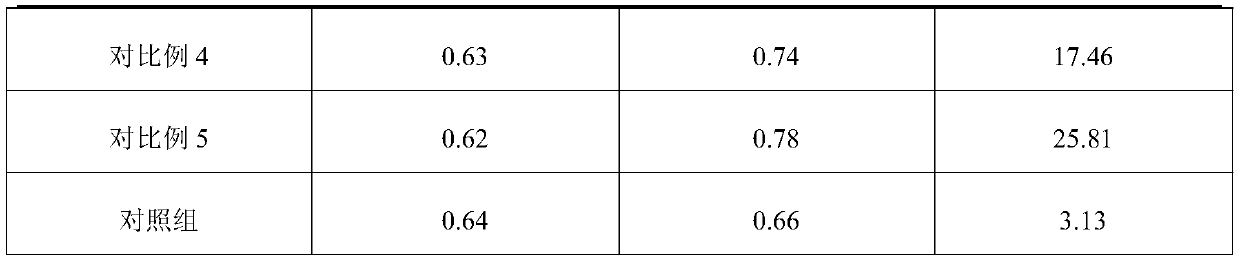

Examples

Embodiment 1

[0039] A preparation process of silk fibroin freeze-dried powder, the specific steps are as follows:

[0040] (1) first extract silk fibroin to obtain a silk fibroin solution;

[0041] (2) Then add elastase to realize the enzymolysis of silk fibroin, add starch, ultrasonically oscillate evenly, then add β-amylase and pullulanase to realize the enzymolysis of starch, filter to obtain a mixed solution;

[0042] (3) Then slowly drop the mixed solution into ethanol while stirring, add polyethylene glycol diglycidyl ether after the dropwise addition, and react at 50°C for 80 minutes;

[0043] (4) freeze-thaw treatment, sterilization, freeze-drying, and packaging to obtain the above-mentioned freeze-dried silk fibroin powder.

[0044] Wherein, the specific method of the step (1) is: first degumming the silk, and then hydrolyzing it to obtain the silk fibroin solution. The silk is mulberry silk. The specific method of degumming treatment is as follows: soak silk in 0.1% sodium car...

Embodiment 2

[0054] A preparation process of silk fibroin freeze-dried powder, the specific steps are as follows:

[0055] (1) first extract silk fibroin to obtain a silk fibroin solution;

[0056] (2) Then add elastase to realize the enzymolysis of silk fibroin, add starch, ultrasonically oscillate evenly, then add β-amylase and pullulanase to realize the enzymolysis of starch, filter to obtain a mixed solution;

[0057] (3) Slowly add the mixed solution into ethanol dropwise while stirring, add polyethylene glycol diglycidyl ether after the dropwise addition, and react at 55°C for 70 minutes;

[0058] (4) freeze-thaw treatment, sterilization, freeze-drying, and packaging to obtain the above-mentioned freeze-dried silk fibroin powder.

[0059] Wherein, the specific method of the step (1) is: first degumming the silk, and then hydrolyzing it to obtain the silk fibroin solution. The silk is tussah silk. The specific method of degumming treatment is: soak silk in 0.05% sodium carbonate aq...

Embodiment 3

[0069] A preparation process of silk fibroin freeze-dried powder, the specific steps are as follows:

[0070] (1) first extract silk fibroin to obtain a silk fibroin solution;

[0071] (2) Then add elastase to realize the enzymolysis of silk fibroin, add starch, ultrasonically oscillate evenly, then add β-amylase and pullulanase to realize the enzymolysis of starch, filter to obtain a mixed solution;

[0072] (3) Slowly add the mixed solution into ethanol dropwise while stirring, add polyethylene glycol diglycidyl ether after the dropwise addition, and react at 53°C for 75 minutes;

[0073] (4) freeze-thaw treatment, sterilization, freeze-drying, and packaging to obtain the above-mentioned freeze-dried silk fibroin powder.

[0074] Wherein, the specific method of the step (1) is: first degumming the silk, and then hydrolyzing it to obtain the silk fibroin solution. The silk is celestial silk. The specific method of degumming treatment is: immerse silk in 0.08% sodium carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com