Element-doped diamond-like carbon film modified battery negative electrode and preparation method and application thereof

A diamond film and element doping technology, which is applied in electrode manufacturing, battery electrodes, negative electrodes, etc., can solve the problems of easy volume expansion, unstable battery performance, and short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

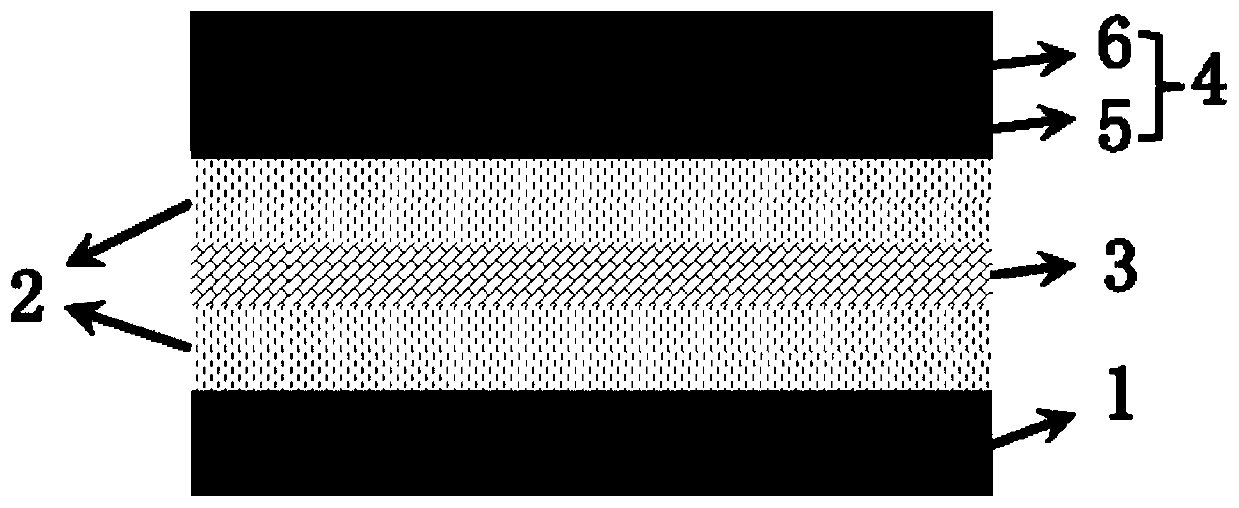

[0033] Correspondingly, the present invention also provides a method for preparing an element-doped diamond-like carbon film modified battery negative electrode, comprising the following steps:

[0034] S01. Provide a metal foil material;

[0035] S02. Prepare an element-doped diamond-like film on any side of the metal foil material to obtain a battery negative electrode modified by the element-doped diamond-like film; the doping element in the element-doped diamond-like film is selected from F, At least one of N, P, Fe, Co, Ni, W;

[0036] Wherein, the method for preparing an element-doped diamond-like carbon film on any side of the metal foil material is selected from at least one of magnetron sputtering, plasma chemical vapor deposition, ion beam assisted deposition, pulsed laser deposition, and filtered cathodic vacuum arc deposition. kind.

[0037] Specifically, in the above step S01, a metal foil material is provided, preferably, the metal foil material is at least one...

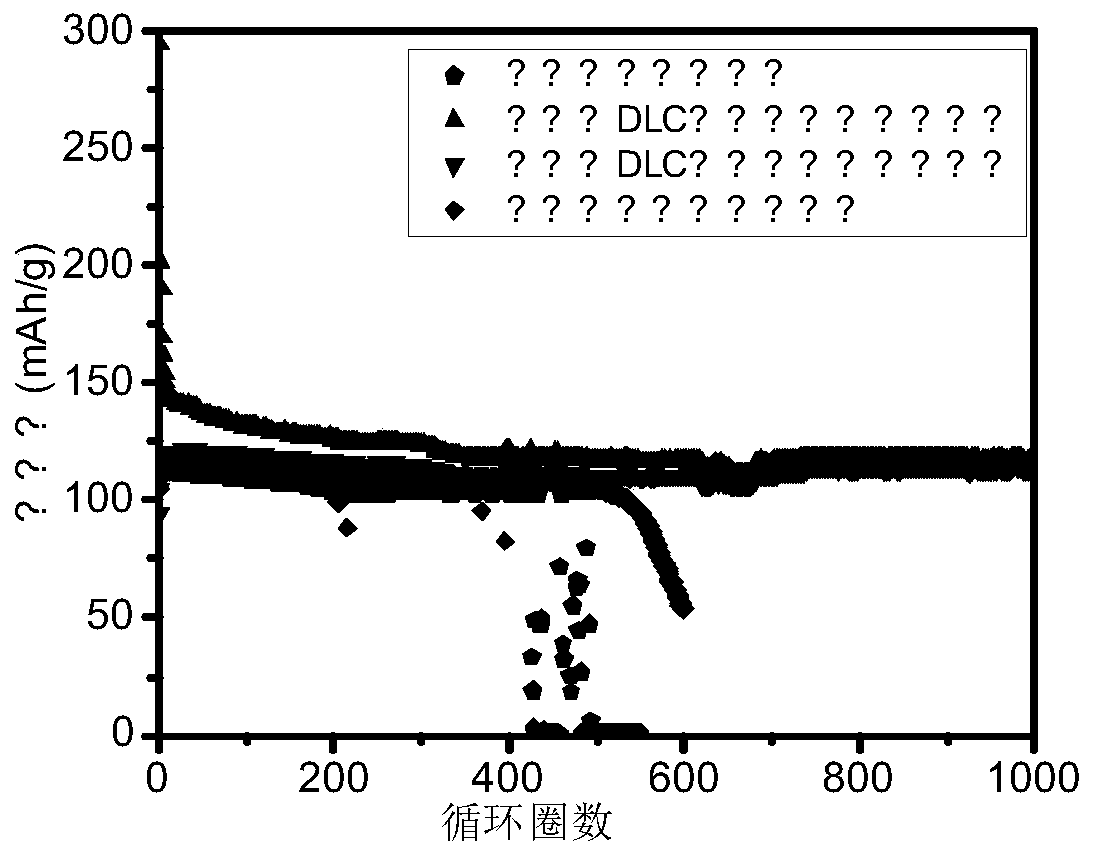

Embodiment 1

[0071] The positive electrode, the negative electrode, the electrolyte solution and the diaphragm of the battery are respectively prepared and assembled, wherein the negative electrode is an aluminum negative electrode modified with a fluorine-doped diamond-like film.

[0072] Preparation of negative electrode: The aluminum negative electrode modified by the fluorine-doped diamond-like film is prepared by magnetron sputtering, including the following steps:

[0073] Provide a metal aluminum foil material, and carry out surface cleaning and drying treatment on the metal foil material; specifically, the surface cleaning is: control the pressure at 10MPa, sandblast the metal aluminum foil for 30s, and then use deionized water and ethanol alternately Washing several times; the drying process is as follows: the metal foil obtained by the above cleaning is placed in a vacuum box to dry.

[0074] Put the processed metal foil material into the magnetron sputtering coating machine, vac...

Embodiment 2

[0085] Compared with the method of Example 1, the "coating time is 15min" in the step of preparing the aluminum negative electrode modified by the fluorine-doped diamond-like film by magnetron sputtering is replaced with "the coating time is 30min"; The other steps are the same as in Example 1 to manufacture a battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com