System and process for preparing synthetic gas through co-gasification of coal and biomass

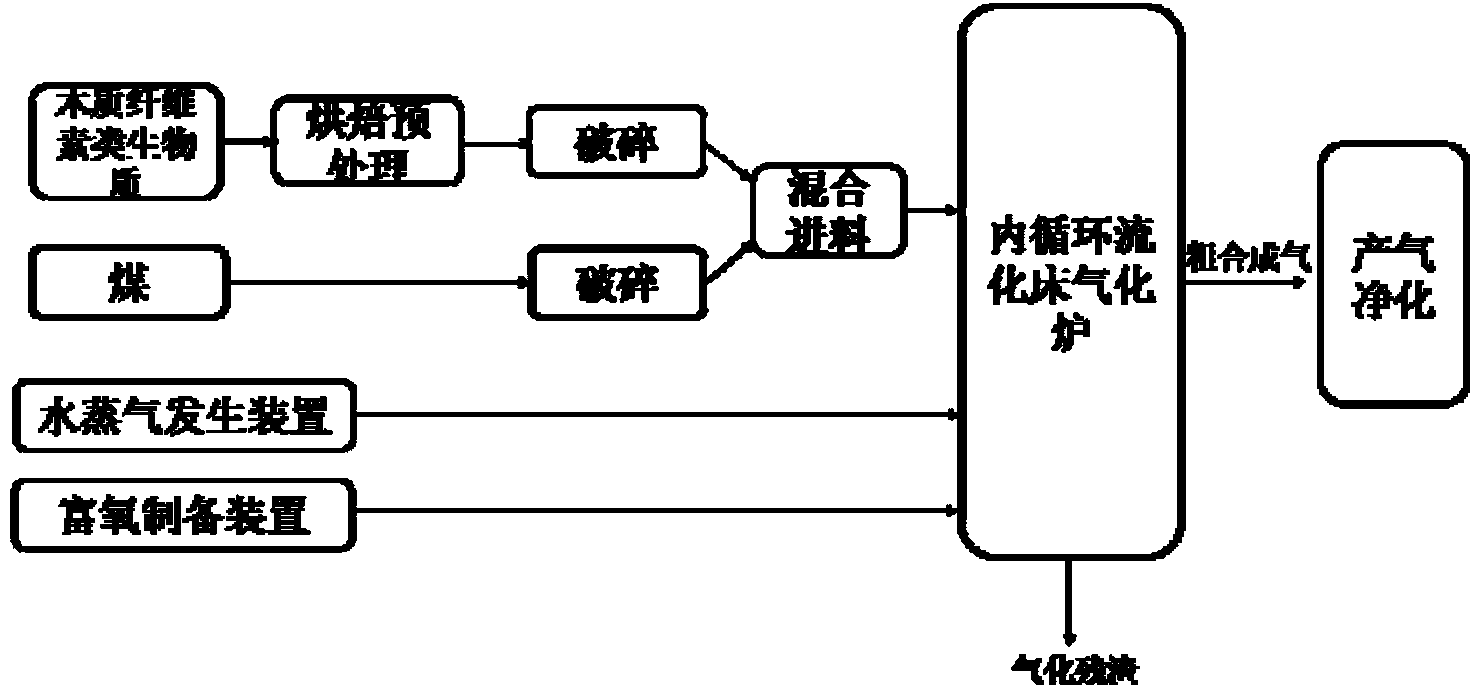

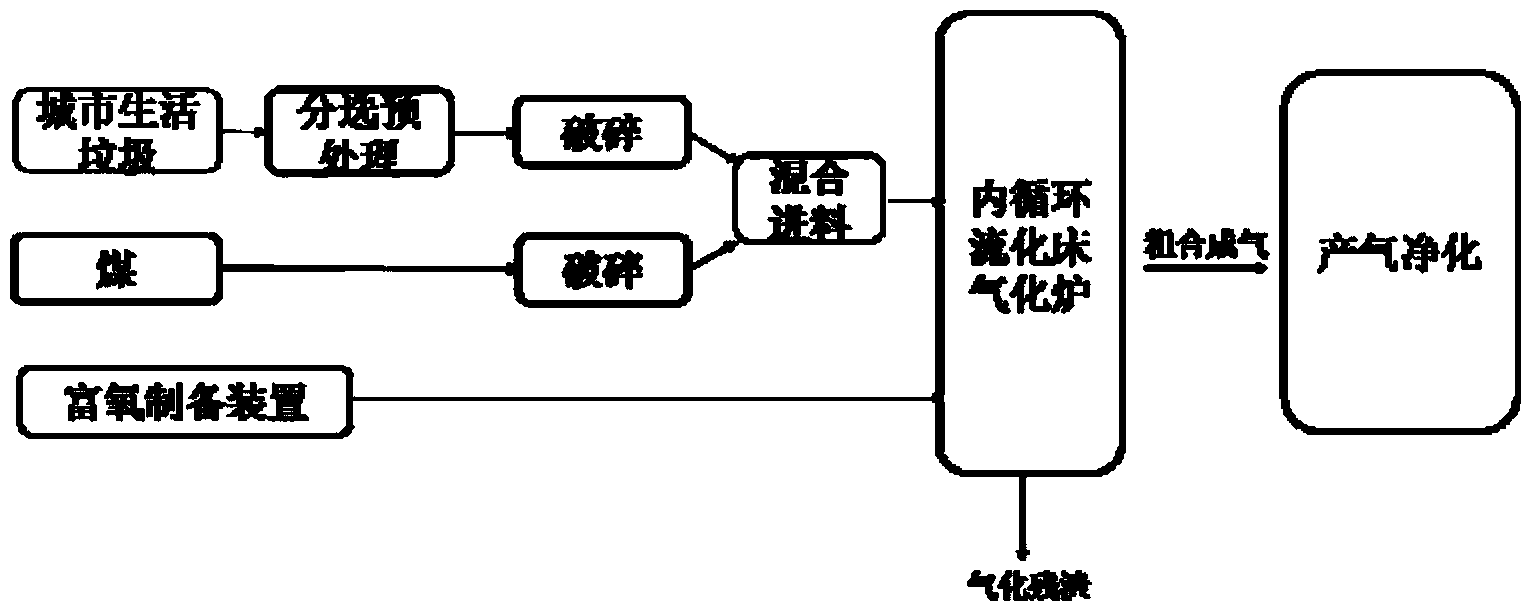

A biomass and syngas technology, which is applied in the gasification of granular/powdered fuel, petroleum industry, and the manufacture of combustible gas, etc., can solve the problem of poor process adaptability of co-gasification fluidized bed reactors and consideration of pretreatment for different types of biomass. The method and mixing degree are greatly affected by the characteristics of the raw materials, etc., to achieve the effects of good load regulation, good fuel adaptability, and less slag discharge and carbon residue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

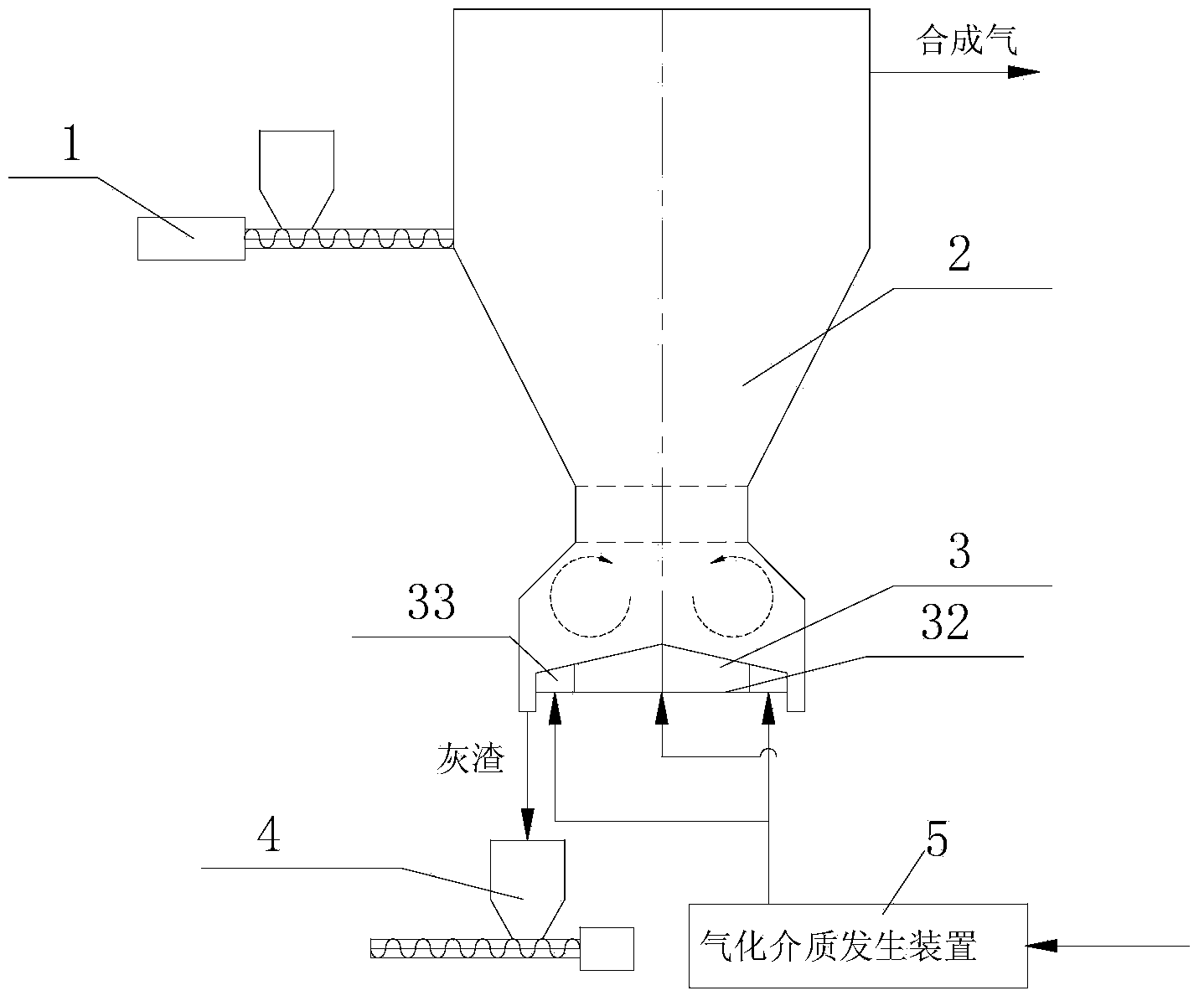

[0036] see Figure 1 to Figure 4 As shown, a coal and biomass co-gasification synthesis gas production system in the present invention includes a feeding device 1 , a gasification furnace body 2 and a gasification medium generating device 5 .

[0037] The gasification furnace body 2 is composed of a lower dense-phase area and an upper dilute-phase area. A multi-chamber air distribution device 3 is arranged at the bottom of the dense-phase area. The multi-air chamber air distribution device 3 is connected to the outlet of the gasification medium generating device 5 ; Multi-chamber air distribution device 3 can adopt conical ("∧") or inverted conical ("∨") air distribution methods according to different working conditions. The feeding device 1 is connected to the gasifier body 2 at the junction of the dense phase area and the dilute phase area; a slag discharge device 4 is connected to the slag outlet between the air distribution device 3 of the multi-air chamber and the gasifie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com