A gasification process for hydrocarbon-containing raw materials using an upper-mounted multi-channel single nozzle

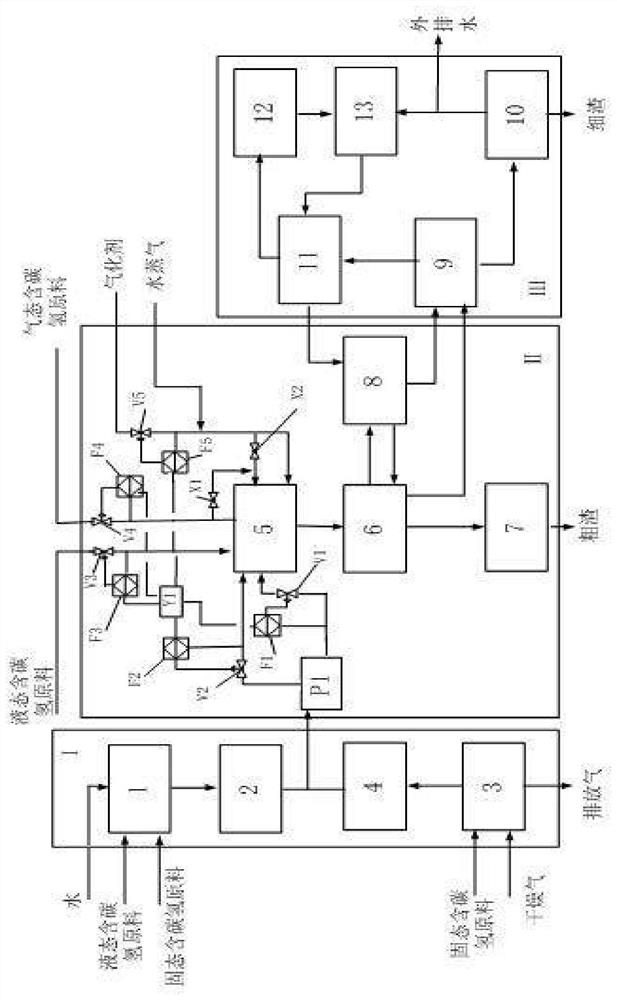

A technology of hydrocarbon raw materials and hydrogen raw materials, which is applied in the gasification process of hydrocarbon-containing raw materials, can solve problems that are prone to danger and difficult to gasify, transform and utilize multiple raw materials at the same time, so as to improve gasification efficiency, reduce equipment and Operating cost, the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] This embodiment includes the following steps:

[0069] Step 1. Pretreatment of solid block hydrocarbon-containing raw materials: Send 143.3t of Shaanxi Shenfu bituminous coal and 53t of water into wet grinding equipment 1, and simultaneously feed 2.5t of aqueous solution containing 10wt% surfactant sodium naphthalenesulfonate, Then the above-mentioned materials are fully mixed and ground to obtain a coal-water slurry with a coal content of 63wt% and good fluidity and stability, and then the coal-water slurry is transported to the raw material slurry storage tank 2 for storage; The water content of fubituminous coal is 12.77wt%, and the particle size is freely distributed between 1mm and 20mm; the particle size of coal in the coal-water slurry is all less than 0.1mm and the particle size of 35wt% coal is greater than 0.075mm;

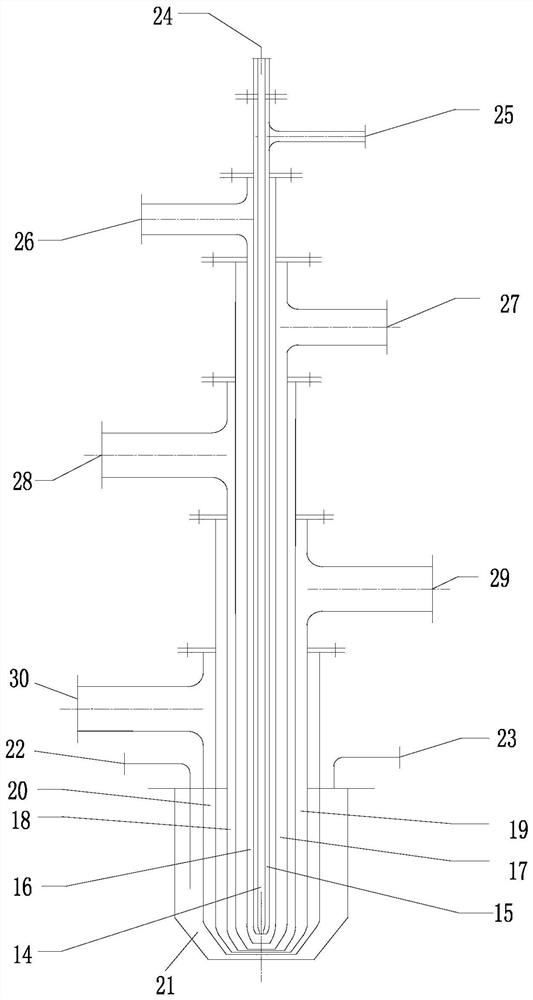

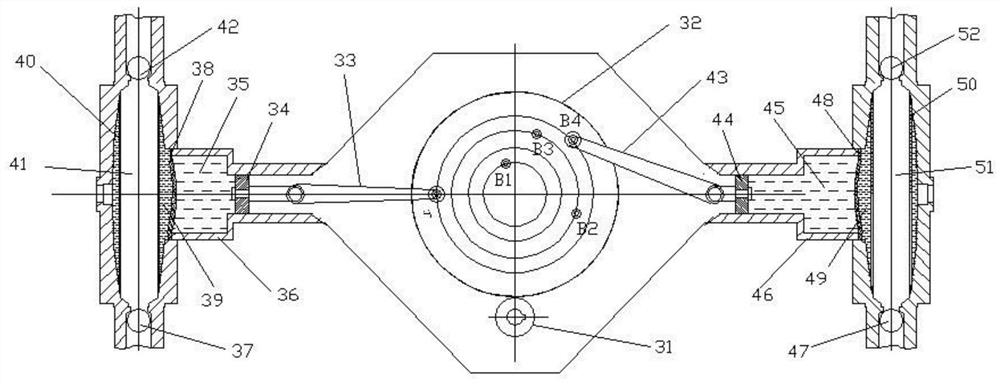

[0070]Step 2, raw material gasification: the coal water slurry obtained in step 1 and the high-purity oxygen with a volume purity of 99.6% are re...

Embodiment 2

[0080] This embodiment includes the following steps:

[0081] Step 1. Pretreatment of solid block hydrocarbon-containing raw materials: Send 53.6t of Shaanxi Shenfu bituminous coal and 20.5t of water into wet grinding equipment 1, and simultaneously feed 0.5t of an aqueous solution containing 25wt% sodium lignosulfonate, and then The above materials are fully mixed and ground to obtain a coal-water slurry with a coal content of 55wt% and good fluidity and stability, and then the coal-water slurry is transported to the raw material slurry storage tank 2 for storage; the Shaanxi Shenfu The water content of the bituminous coal is 14.78wt%, and the particle size is freely distributed between 1mm and 20mm; the particle size of the coal in the coal-water slurry is all less than 0.1mm and the particle size of 35wt% of the coal is greater than 0.075mm;

[0082] Step 2, raw material gasification: the coal water slurry, heavy oil and high-purity oxygen with a volume purity of 99.6% obta...

Embodiment 3

[0092] This embodiment includes the following steps:

[0093] Step 1. Pretreatment of solid block hydrocarbon-containing raw materials: Send 52.9t of Shaanxi Shenfu bituminous coal and 29.6t of water into wet grinding equipment 1, and at the same time feed 1000kg of sodium humate containing 25wt% special additive for coal-water slurry aqueous solution, and then the above-mentioned materials are fully mixed and ground to obtain a coal-water slurry with a coal content of 60wt% and good fluidity and stability, and then the coal-water slurry is transported to the raw material slurry storage tank 2 for storage; Shaanxi Shenfu bituminous coal has a moisture content of 5.66wt%, a particle size of less than 10mm and a free distribution;

[0094] Step 2, raw material gasification: the coal-water slurry, natural gas and high-purity oxygen with a volume purity of 90% obtained in step 1 are respectively passed through the hydrocarbon-containing raw material flow channel and the gasificati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com