Microchannel flat tube wound heat exchanger with variable hydraulic diameter in the same flow path

A hydraulic diameter, micro-channel technology, applied in heat exchanger types, indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of pressure drop in the inlet section, deviation of heat transfer performance in the outlet section, etc. The effect of pressure resistance, reducing flow resistance, and enhancing heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

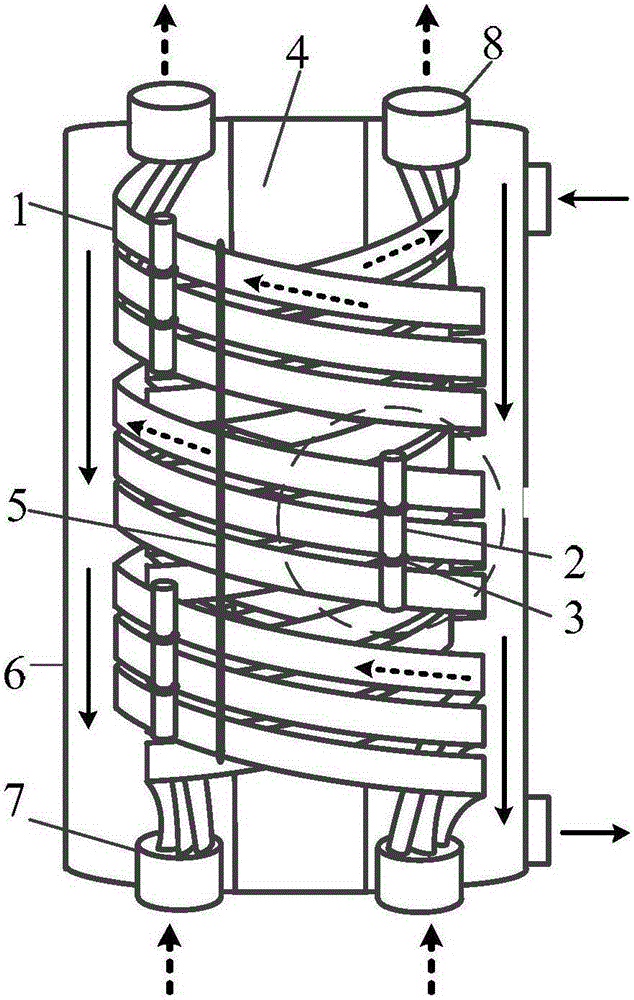

[0022] Such as figure 1 and figure 2 As shown, the microchannel flat tube winding heat exchanger with variable hydraulic diameter in the same flow path provided by the present invention includes a heat exchanger body; the housing 6 of the heat exchanger body is provided with three microchannel flat tubes 1 The three micro-channel flat tubes 1 are coiled around the central tube 4 in the shell 6 as the center. Openings at both ends of the microchannel flat tube 1 are respectively connected with an inlet tube 7 at the bottom of the housing 6 and an outlet tube 8 at the top of the housing 6 .

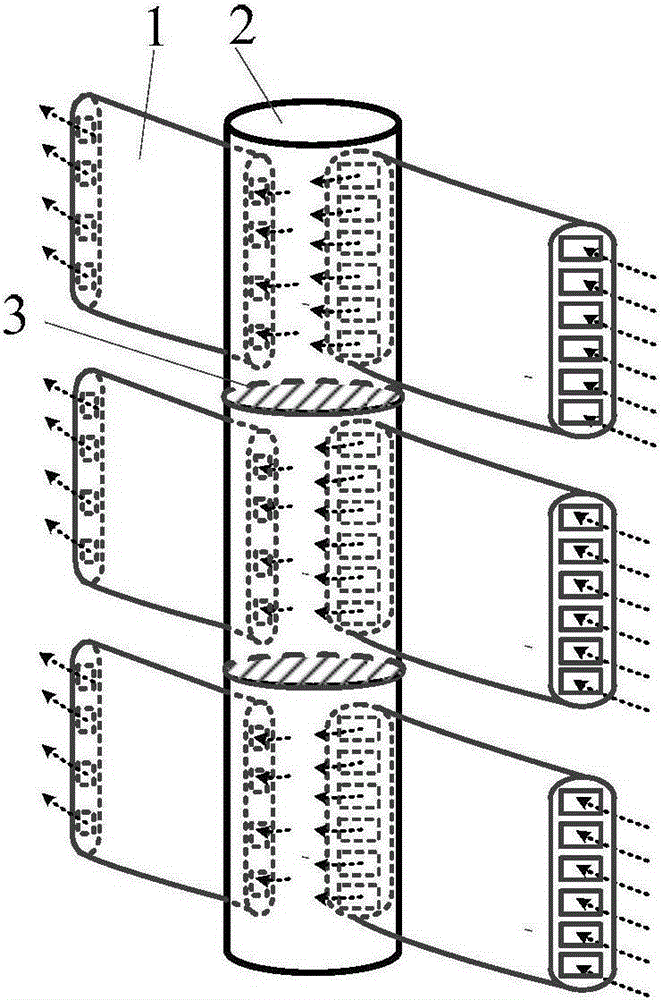

[0023] Such as figure 2 As shown, the cavity of each microchannel flat tube 3 is provided with multiple microchannel flow paths (not marked in the figure). The three micro-channel flat tubes of each layer o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com