Preparation method of ring-opening epoxidized soybean oil modified sulfonated waterborne polyurethane

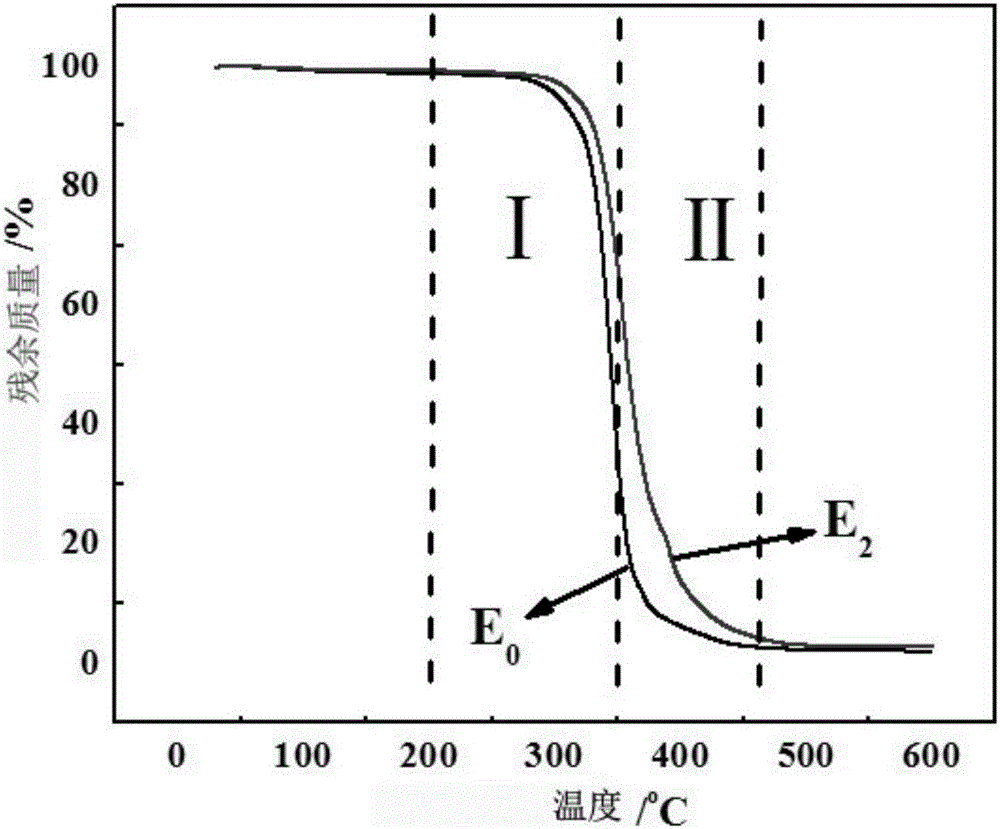

A technology of epoxidized soybean oil and water-based polyurethane, which is applied in the direction of carboxylate preparation, organic compound preparation, chemical instruments and methods, etc., can solve the problems of poor water resistance and heat resistance of water-based polyurethane, and achieve excellent flexibility and Tensile properties, improvement of water resistance and heat resistance, effects of relieving environmental stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: A kind of preparation method of ring-opening epoxy soybean oil modified sulfonic acid type waterborne polyurethane

[0031] The preparation method is sequentially composed of two parts: the preparation of the first part of ring-opening epoxy soybean oil and the second part of the synthesis of sulfonic acid type waterborne polyurethane;

[0032] The preparation of described first part ring-opening epoxy soybean oil comprises the following steps:

[0033] (1) Add 60g of epoxidized soybean oil and 79g of isooctyl alcohol into the first reaction kettle, stir to mix them well, then slowly add 0.48g of catalyst fluoboric acid into the first reaction kettle, and react at 100°C for 2h ; Wherein, the epoxy group mass percentage content of epoxy soybean oil is 6.1% of epoxy soybean oil quality;

[0034] (2) After the reaction is over, move it to a separatory funnel, add ethyl acetate to the feed liquid to dissolve, add water to wash until neutral; then use a rotary...

Embodiment 2

[0042] Embodiment 2: A kind of preparation method of ring-opening epoxy soybean oil modified sulfonic acid type waterborne polyurethane

[0043]The preparation method is sequentially composed of two parts: the preparation of the first part of ring-opening epoxy soybean oil and the second part of the synthesis of sulfonic acid type waterborne polyurethane;

[0044] The preparation of described first part ring-opening epoxy soybean oil comprises the following steps:

[0045] (1) Add 60g of epoxidized soybean oil and 79g of isooctyl alcohol into the first reaction kettle, stir to mix them well, then slowly add 0.48g of catalyst fluoboric acid into the first reaction kettle, and react at 100°C for 2h ; Wherein, the epoxy group mass percentage content of epoxy soybean oil is 6.1% of epoxy soybean oil quality;

[0046] (2) After the reaction is over, move it to a separatory funnel, add ethyl acetate to the feed liquid to dissolve, add water to wash until neutral; then use a rotary ...

Embodiment 3

[0054] Example 3: A preparation method of ring-opening epoxy soybean oil modified sulfonic acid type waterborne polyurethane

[0055] The preparation method is sequentially composed of two parts: the preparation of the first part of ring-opening epoxy soybean oil and the second part of the synthesis of sulfonic acid type waterborne polyurethane;

[0056] The preparation of described first part ring-opening epoxy soybean oil comprises the following steps:

[0057] (1) Add 60g of epoxidized soybean oil and 79g of isooctyl alcohol into the first reaction kettle, stir to mix them well, then slowly add 0.48g of catalyst fluoboric acid into the first reaction kettle, and react at 100°C for 2h ; Wherein, the epoxy group mass percentage content of epoxy soybean oil is 6.1% of epoxy soybean oil quality;

[0058] (2) After the reaction is over, move it to a separatory funnel, add ethyl acetate to the feed liquid to dissolve, add water to wash until neutral; then use a rotary evaporator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com