Device and method for rapid conveying and unloading of shale gas hydrate slurry

A hydrate slurry and unloading device technology, which is applied in separation methods, article transport vehicles, transportation and packaging, etc., can solve the problems of production capacity uncertainty, shale gas production decline rate, pipeline network pressure and production contradiction, etc. Achieve the effect of ensuring safe storage and avoiding gasification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

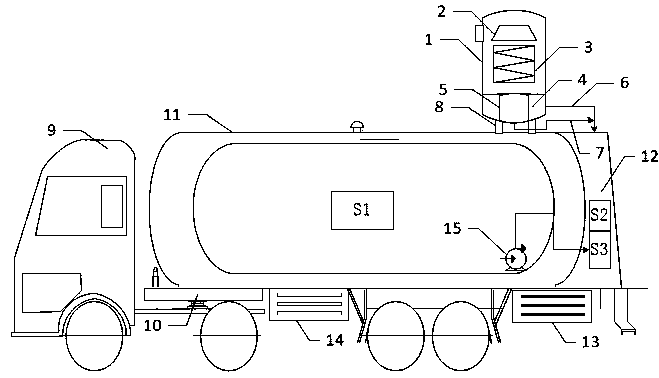

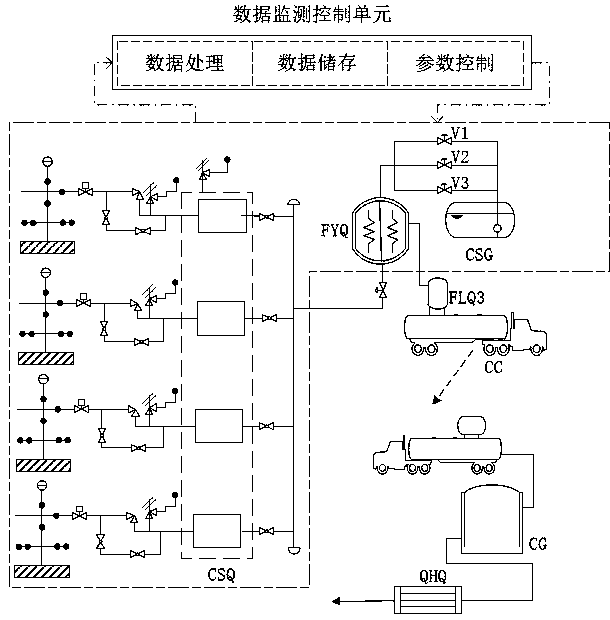

[0048] In this example, figure 1 It is a schematic structural diagram of the rapid transfer and unloading device for shale gas hydrate slurry in an embodiment of the present invention. The rapid transfer and unloading device for shale gas hydrate slurry includes a hydrate slurry separation unit, a slurry storage and transfer unit, and a rapid slurry unloading unit;

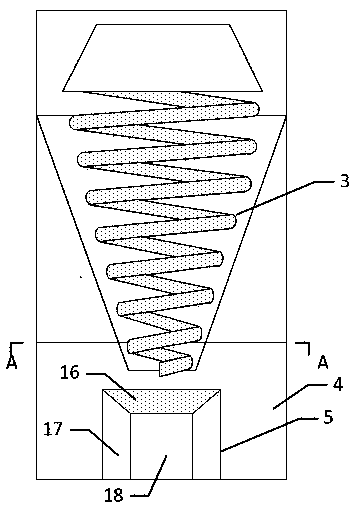

[0049] The hydrate slurry separation unit includes a slurry dehydration separator 1, a rotating wheel 2, a spiral flow channel 3, a first liquid storage chamber 4, a slurry separation chamber 5, a first cooling water return pipe 6, and a second cooling water return pipe 7 , bracket 8; the slurry storage and transfer unit includes a headstock 9, a tank truck chassis 10, a slurry vehicle storage tank 11, an operation box 12, an emergency gasification system S1, a safety instrument system S2, and a pipeline system S3; the slurry is quickly unloaded The unit includes an air-temperature vaporizer 13, an electric heatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com