Air temperature adjusting system for heat exchange type vehicles and vessels

An air temperature and regulation system technology, applied in the charging system, combustion air/combustion-air treatment, exhaust device, etc., can solve the problems of low exhaust heat energy recovery efficiency, limited heat energy recovery structure, and no internal combustion engine, etc. Improve the effect of heat dissipation, good heat exchange effect, and fast gasification speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

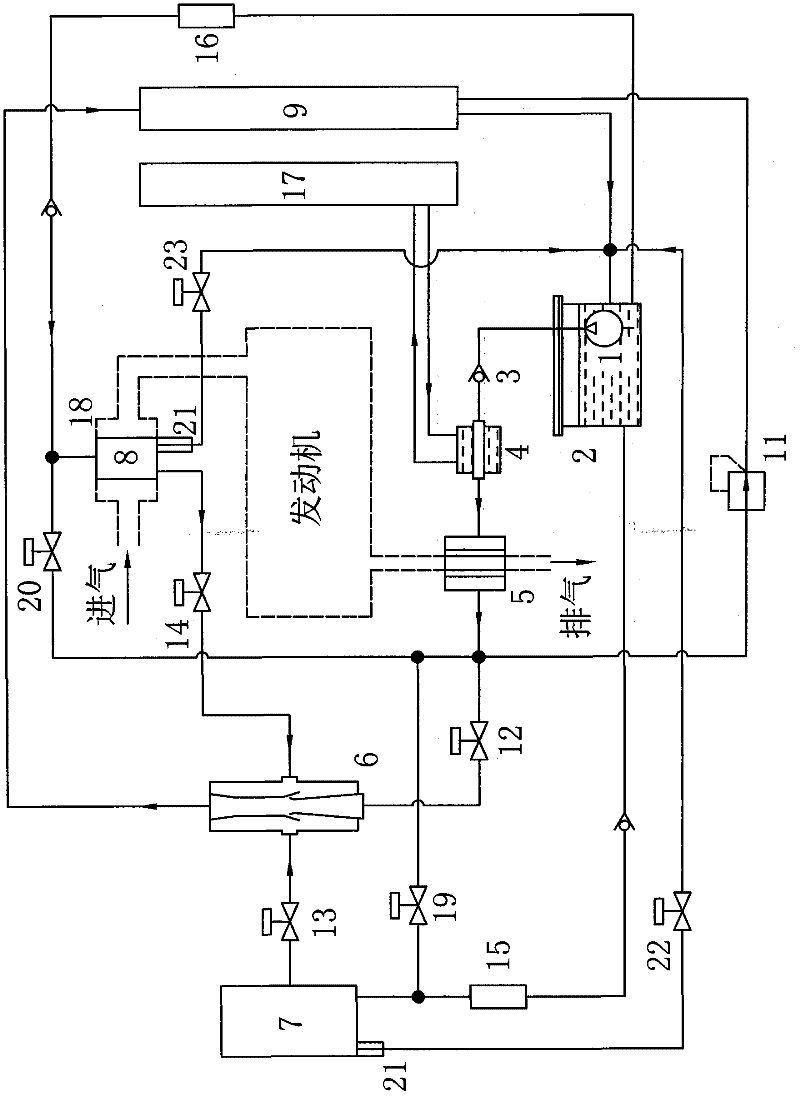

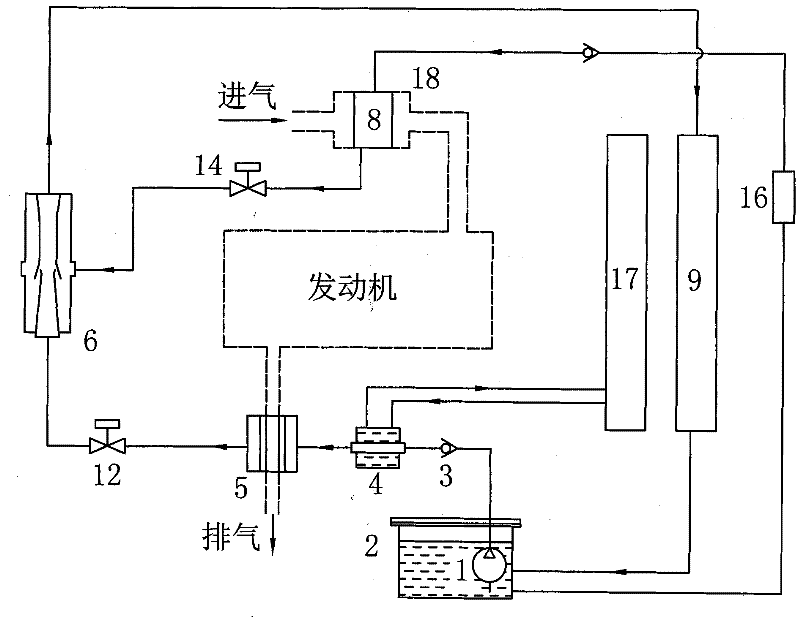

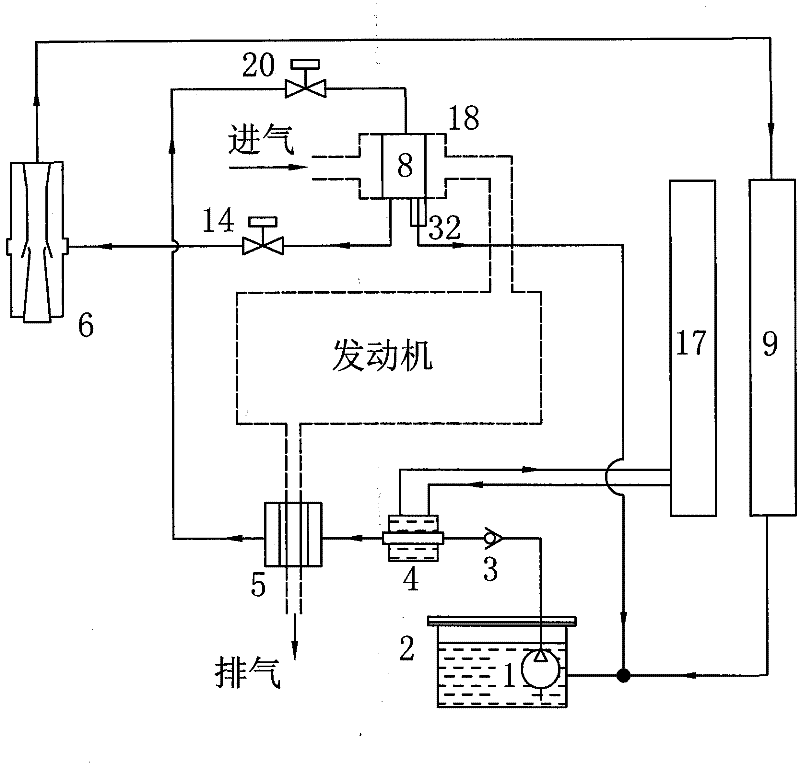

[0034] Embodiment: a kind of heat exchange type car and ship air temperature regulation system of the present invention, as attached figure 1 It includes an evaporator using alcohol refrigerant, a condenser 9, an ejector 6 that can suck the refrigerant in the evaporator and output it to the condenser 9, a pump 1, and can absorb the heat of the exhaust gas of the engine through heat exchange. A heater 5 for evaporating the refrigerant and a liquid storage tank 2 , the heater 5 is connected between the injector 6 and the pump 1 through tubes.

[0035] The evaporator includes the air-conditioning evaporator 7 and the intake evaporator 8, or one of the air-conditioning evaporator 7 and the intake evaporator 8; the intake evaporator 8 is arranged on the engine intake pipeline or built in the engine intake filter In 18, the air entering the engine is cooled; the air-conditioning evaporator 7 is located in the cabin and the cabin that need to be cooled to cool down the cabin and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com