Plasma fluid bed gasifying device

A technology of fluidized bed gasification and fluidized bed gasification furnace, applied in the direction of granular/powdered fuel gasification, etc., can solve the problems of large resource consumption, high waste gas, low gasification rate, etc., and achieve fast gasification speed , high gasification efficiency and low waste gas ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

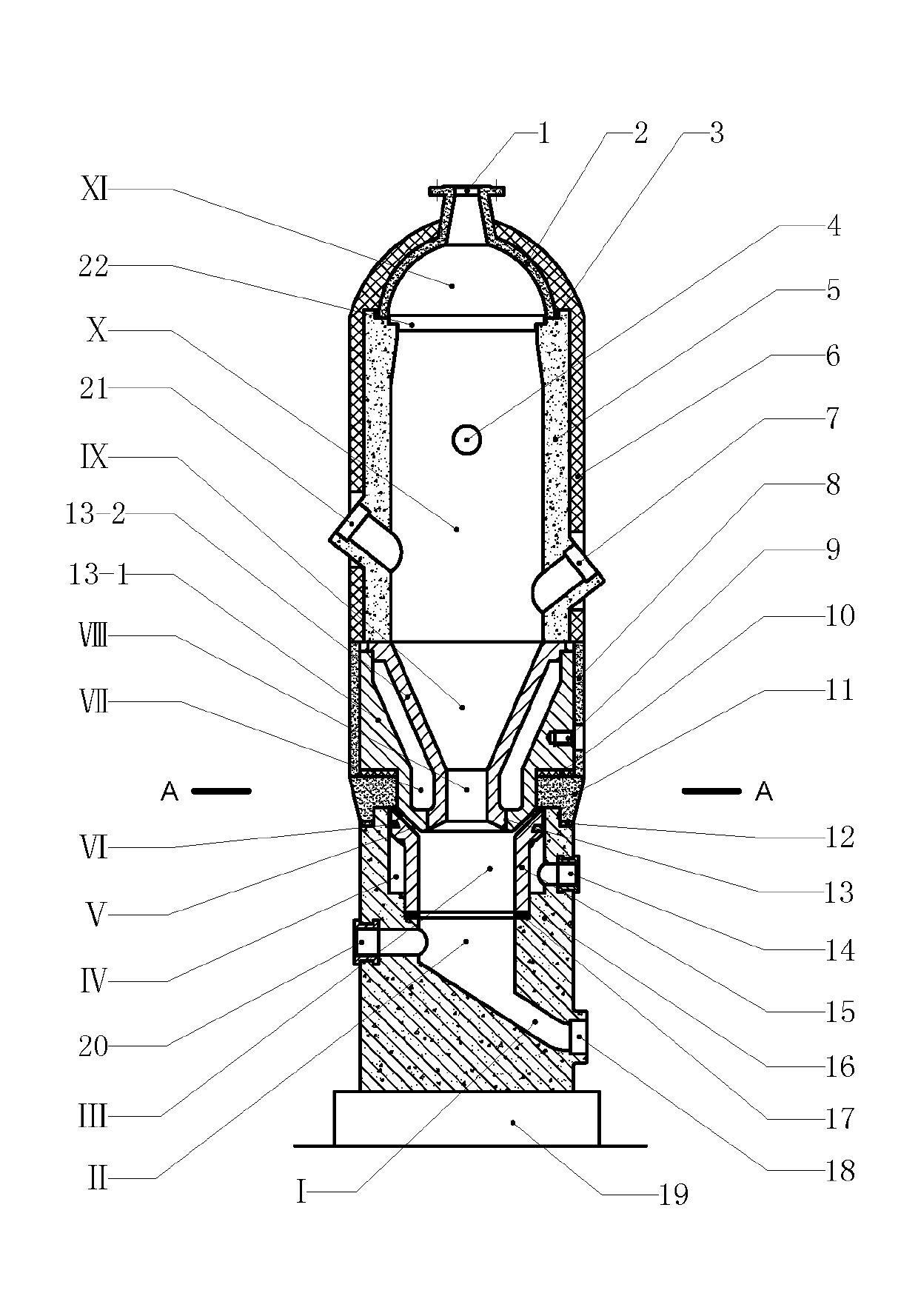

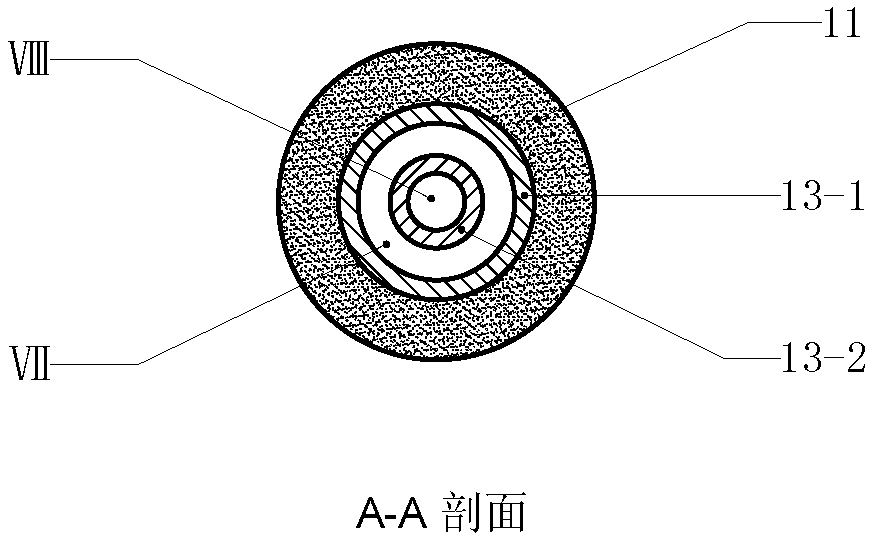

[0030] Example 1 figure 1 In the embodiment shown, the plasma fluidized bed gasifier mainly consists of a top cover (2), an upper furnace body, an insulating connector (11), a lower furnace body (16), an anode (13), and a cathode (15) and the base (19), wherein the top cover (2), the upper furnace body, the anode (13), the insulating connector (11), the lower furnace body (16) and the base (19) are arranged sequentially from top to bottom The cathode (15) is arranged in the upper inner space of the lower furnace body (16), and the inner space in the middle part of the lower furnace body (16) constitutes the gasification agent chamber (II), and the gasification agent chamber (II) has a gasification agent input interface ( 20) access, the lower part of the lower furnace body (16) has a slag discharge channel (I), the slag discharge channel (I) communicates with the gasification agent chamber (II), and the slag discharge channel (I) has a slag discharge port (18) The cathode (15...

Embodiment 2

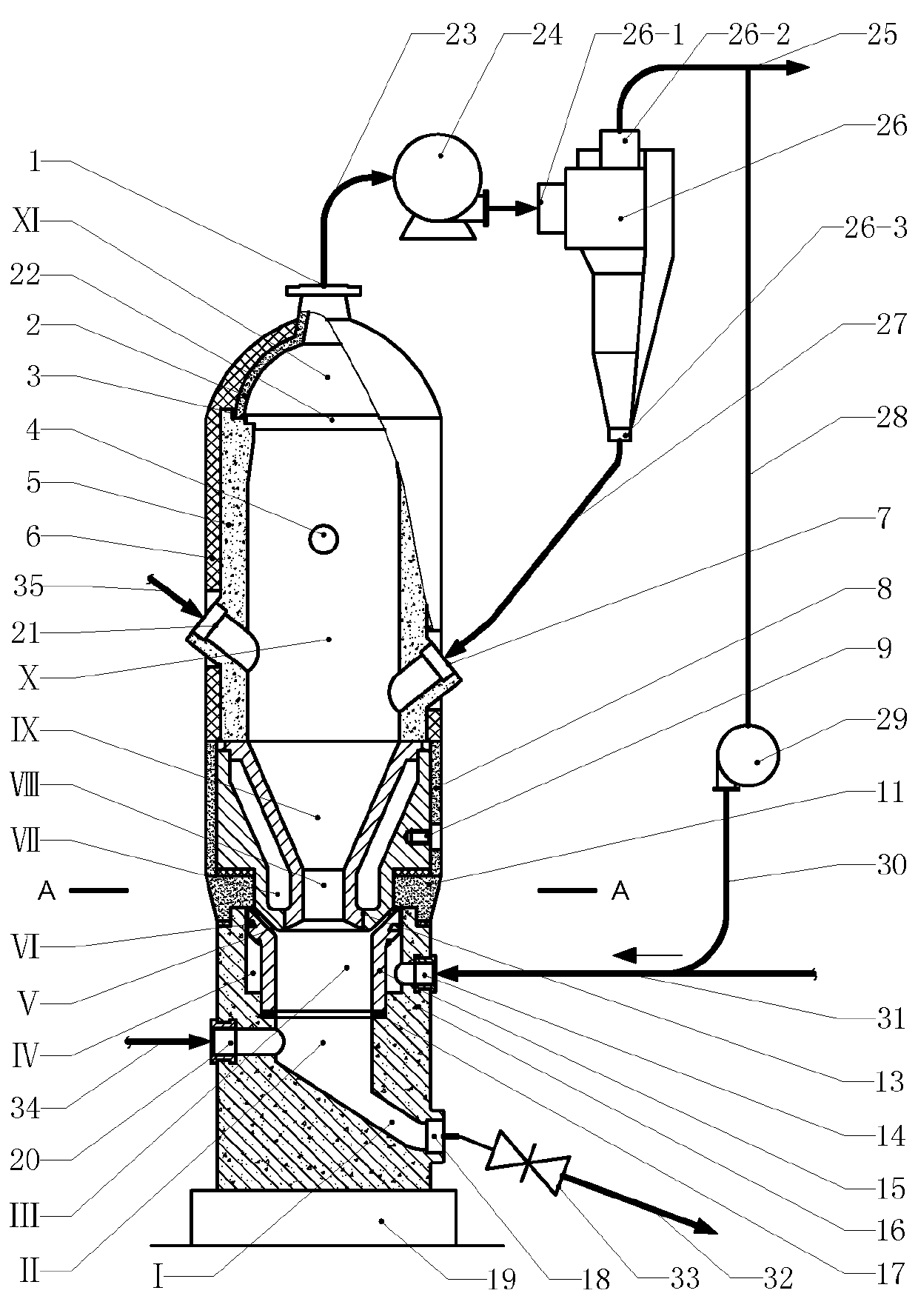

[0031] Example 2 figure 2 In the embodiment shown, the plasma fluidized bed gasification device is composed of a plasma fluidized bed gasifier and equipment outside the furnace, wherein the structure of the plasma fluidized bed gasifier is as described in Example 1, I won’t go into details here; the peripheral equipment mainly includes high-temperature gas blower (24), cyclone separator (26) and syngas delivery pipe (25), and the syngas output interface (1) of plasma fluidized bed gasifier is connected to the The air inlet of the gas fan (24), the air outlet of the high-temperature gas fan (24) are connected to the mixture inlet (26-1) of the cyclone separator (26), and the gaseous substance outlet (26-2) of the cyclone separator (26) Connected to the syngas delivery pipe (25), the solid matter outlet (26-3) of the cyclone separator (26) is connected to the charcoal ash return interface (7); the working gas input interface of the plasma fluidized bed gasifier ( 14) There is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com