Oxygen supply flaming apparatus of biomass gasification furnace

A fire-breathing device and biomass energy technology, which is applied in the details of gasification devices, gasification process, chemical industry, etc., can solve the problems of waste of resources, singleness, and no purification of flue gas, so as to save energy and speed up gas production. The effect of speed and convenience of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

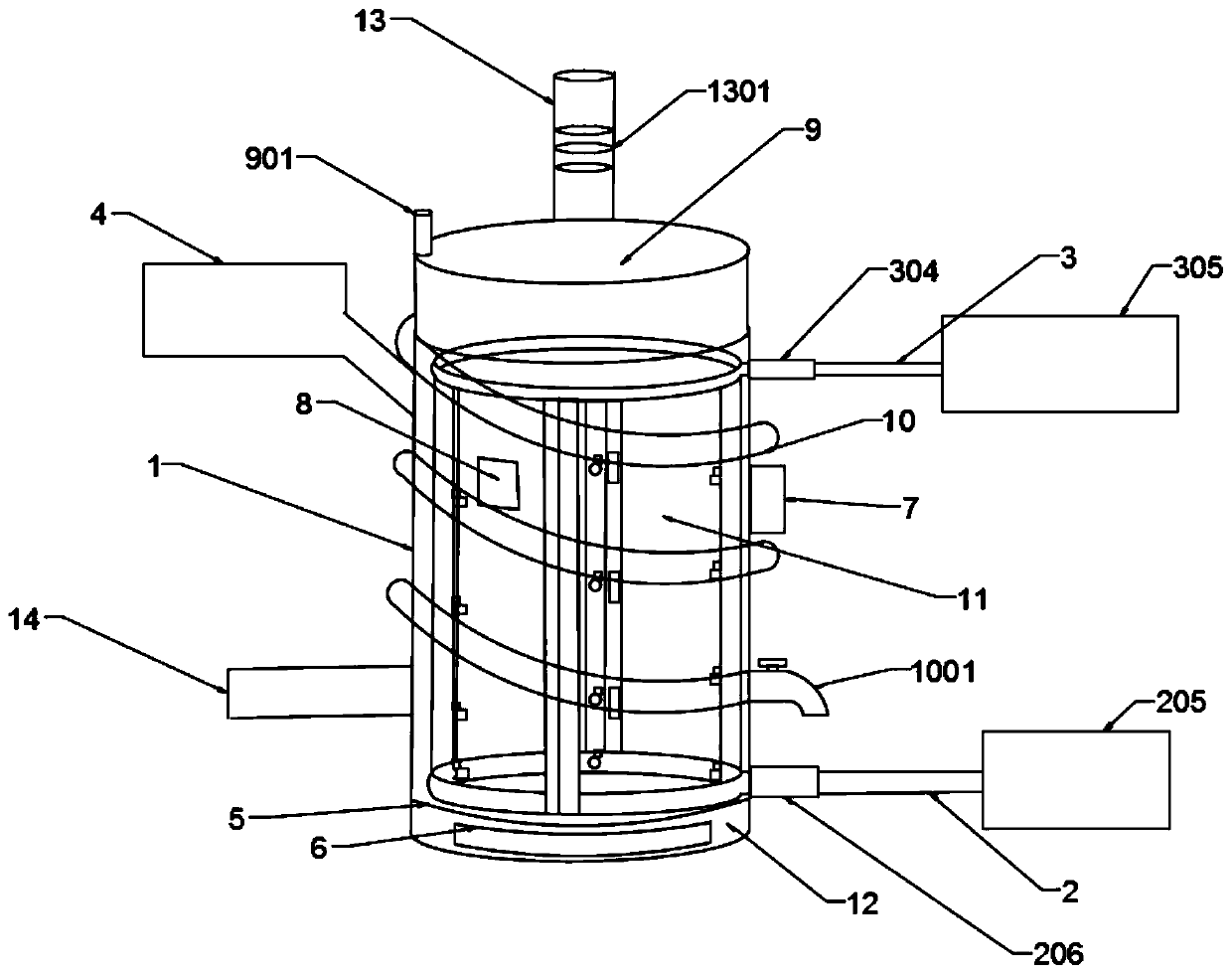

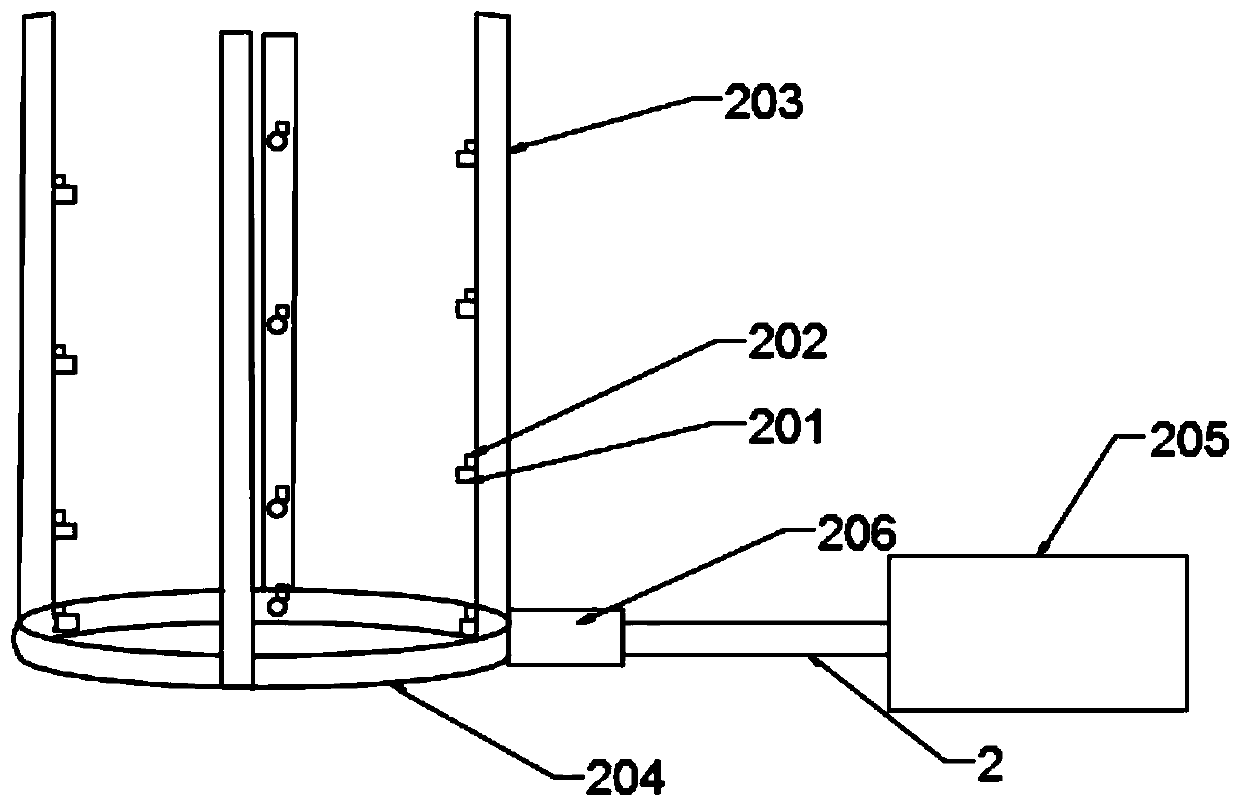

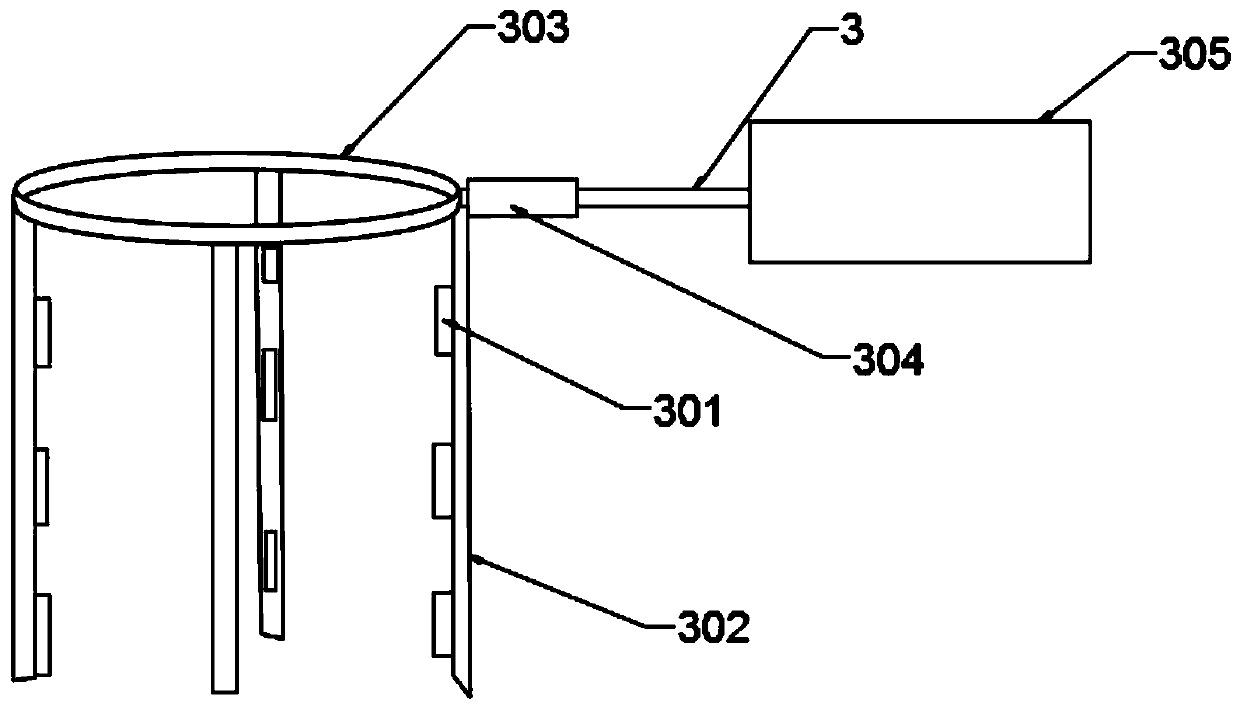

[0027] Example: such as Figure 1-3 As shown, a biomass gasification furnace oxygen supply flame injection device includes a furnace body 1, the top of the furnace body 1 is provided with a water tank 9, the middle part of the furnace body 1 is a combustion chamber 11, and the bottom is an ash storage chamber 12. A layer of filter plate 5 is arranged between the combustion chamber 11 and the ash storage chamber 12, and a flame spraying device 2 is installed in the combustion chamber 11, and the flame spraying device 2 is installed in the combustion chamber 11, and the flame spraying device 2 consists of The bottom ring 204, the first connecting pipe 206 and four oil guide pipes 203 are formed, and the four oil guide pipes 203 are evenly arranged on the bottom ring 204, and the flame outlet 201 is uniformly arranged on the inner side of the bottom ring 204 and on the oil guide pipe 203. Ignition heads 202 are arranged beside the flame vent 201; simultaneously, an oxygen supply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com