Small-grain-diameter lignite gasification device based on vacuum thermal decomposition and gasification method thereof

A small particle size, coal gasification technology, applied in the direction of granular/powdered fuel gasification, can solve the problems of low lignite gasification efficiency, complex production process, and low gas calorific value, and achieve environmental protection and safety. The effect of high combustion calorific value and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

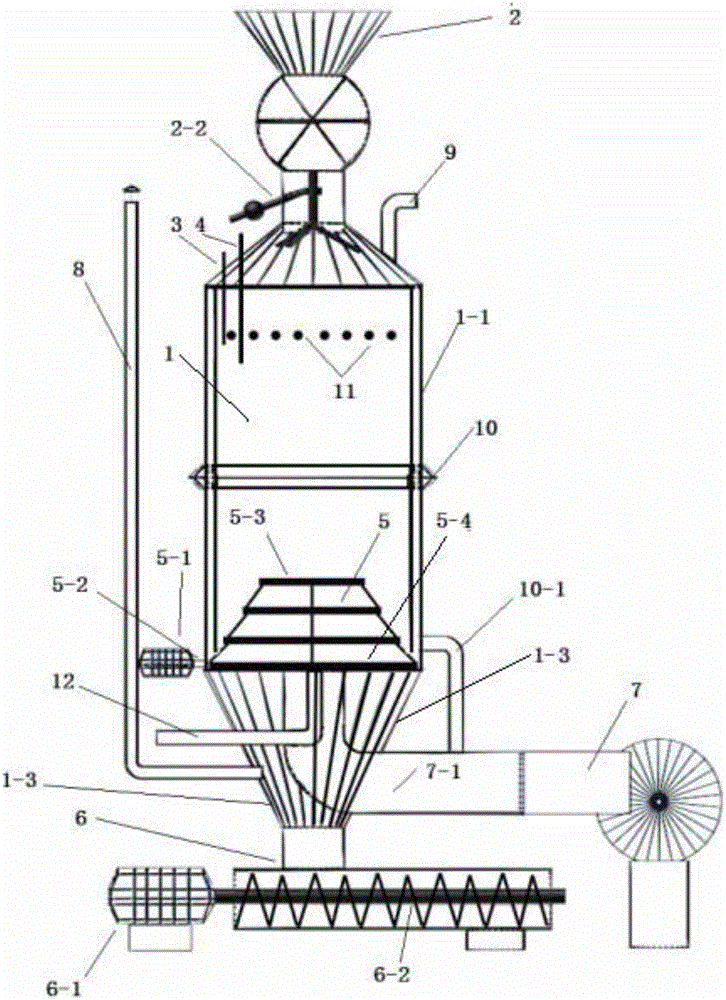

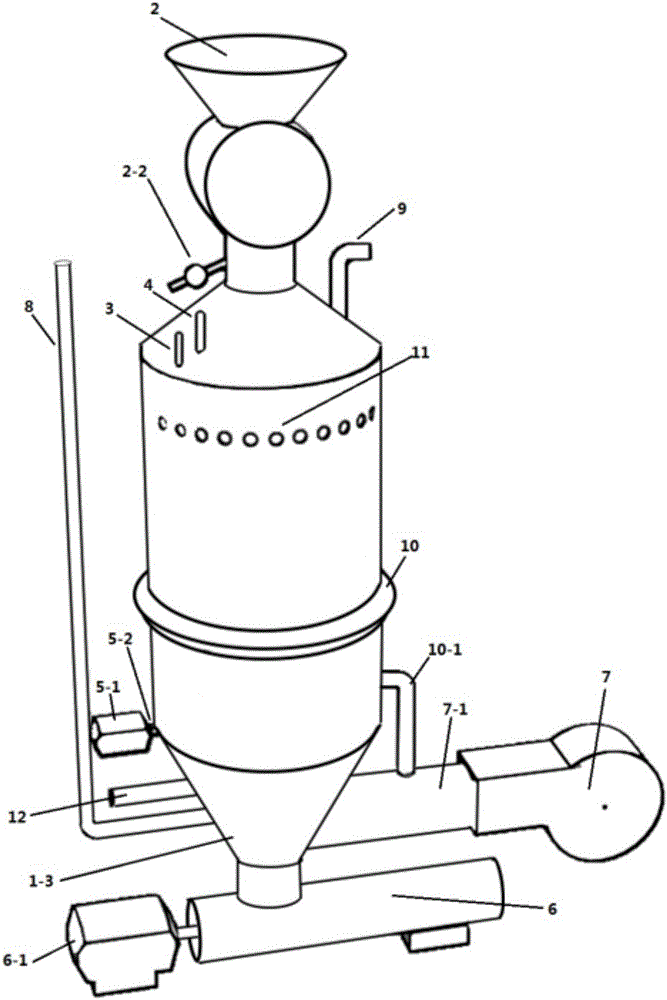

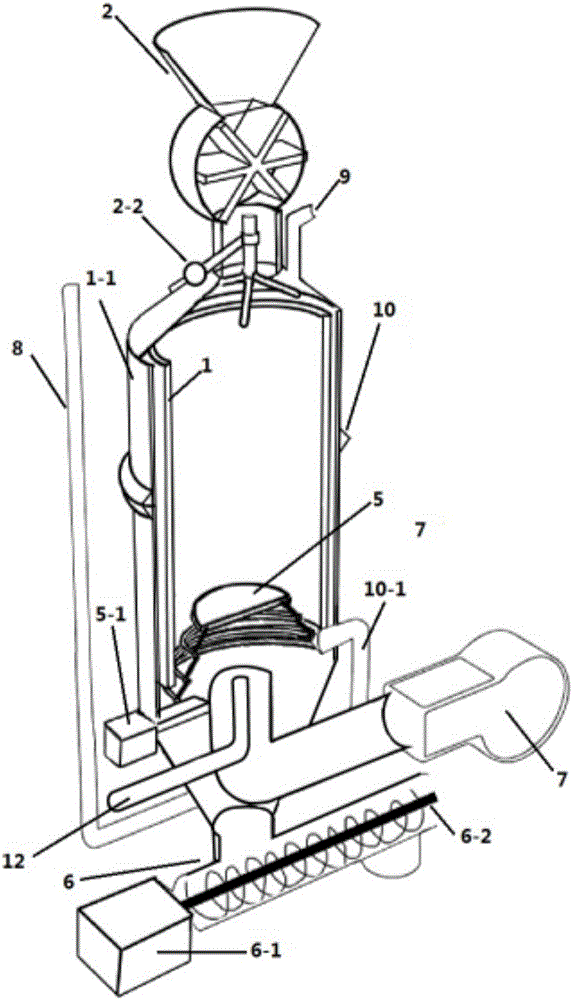

[0031] Specific implementation mode one: combine Figure 1 to Figure 3 Describe this embodiment, present embodiment comprises reactor 1 and furnace cylinder 1-1, offers a plurality of suction ports 11 along the circumferential direction on the upper outer side wall of reactor 1, furnace cylinder 1-1 is installed in reactor 1, And there is a gap between the outer wall of the furnace drum 1-1 and the inner wall of the reactor 1, which is characterized in that: it also includes a charging metering device 2, a full sealing cover 2-1, an intelligent valve 2-2, a first Sensor 3, second sensor 4, rotary ash removal tray 5, screw feeder 6, burner 7, flue 8, exhaust pipe 9 and steam pipe 12, fully sealed cover 2-1 is sealed and installed in reactor 1 The upper end of the top cover, the upper end of the full sealing cover 2-1 is connected with the charging metering device 2, the smart valve 2-2 is installed on the full sealing cover 2-1, the first sensor 3 and the second sensor 4 are in...

specific Embodiment approach 2

[0039] Specific implementation mode two: combination Figure 1 to Figure 3 Illustrate this embodiment, the present embodiment rotary ash removal tray 5 comprises ash removal motor 5-1, drive shaft 5-2, fire grate 5-4 and perforated plate 5-3, and perforated plate 5-3 is fixedly installed in reaction On the inner side wall of the device 1, the grate 5-4 is installed in the reactor 1 below the perforated plate 5-3, and the ash removal motor 5-1 is connected with the perforated plate 5-3 through the transmission shaft 5-2. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0040] Specific implementation mode three: combination Figure 1 to Figure 3 Describe this embodiment, the screw feeder 6 of this embodiment comprises screw motor 6-1 and screw shaft 6-2, and screw feeder 6 communicates with the lower end of reactor 1, and the output end of screw motor 6-1 is connected with the screw shaft 6-2. Axis 6-2 connection. Other compositions and connections are the same as those in the second embodiment.

[0041] Specific implementation mode four: combination Figure 1 to Figure 3 Describe this embodiment, it also includes a burner air duct 7-1 in this embodiment, and the burner 7 is inserted into the rotary ash removal pan 5 through the side wall of the reactor 1 through the burner air duct 7-1. Other compositions and connections are the same as those in the third embodiment.

[0042] Specific implementation mode five: combination Figure 1 to Figure 3 The present embodiment will be described. The burner 7 of the present embodiment is a gas-liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com