Mobile LNG (Liquefied Natural Gas) supply device utilizing residual heat and waste heat

A gas supply device, mobile technology, applied in the container discharge method, equipment loaded into the pressure vessel, gas/liquid distribution and storage, etc., can solve the problem that the long-term stable gas supply and gasification speed of the gasifier cannot be achieved Slow, lack of gas supply safety and other problems, to achieve the effect of compact structure, fast start-up speed, fast gasification speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

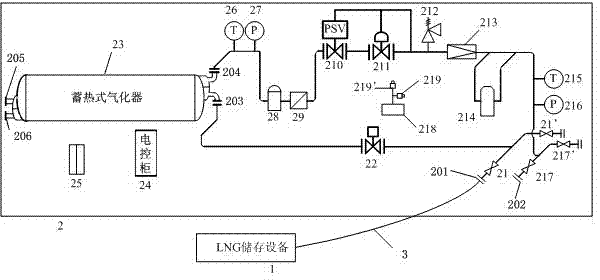

[0024] Such as figure 1 Shown is a schematic structural diagram of a mobile LNG gas supply device utilizing waste heat provided by the present invention, shown in the figure: LNG storage equipment 1, vehicle-mounted gasification pressure regulating container 2, LNG inlet flange 201, natural gas outlet flange 202, Liquid phase inlet flange 203, gas phase outlet flange 204, heating fluid inlet flange 205, heating fluid outlet flange 206, stop valves (21, 21', 217, 217'), emergency shut-off solenoid valve 22, accumulator Thermal vaporizer 23, electric control cabinet 24, portable dry powder fire extinguisher 25, first temperature sensor 26, first pressure sensor 27, over-liquid prevention device 28, filter 29, overpressure cut-off valve 210, pressure regulator 211 , safety release valve 212, flow meter 213, THT odorizer 214, second temperature sensor 215, second pressure sensor 216, combustible gas alarm 218, alarm probe 219, alarm probe 219', pipeline 3.

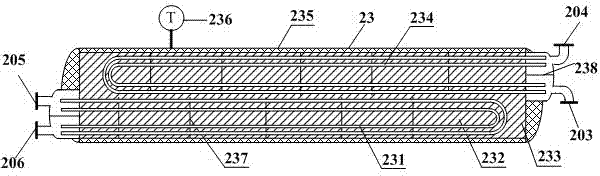

[0025] figure 2 It ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com