Intelligent gasification furnace and control method thereof

A technology of intelligent controller and gasifier, which is applied in the direction of household stove/stove, lighting and heating equipment, solid heating fuel, etc. It can solve the problems of uneven air content in the mixed gas, incomplete combustion of fuel, and low working efficiency of valves, etc. , to achieve the effects of simple structure, fuel saving and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

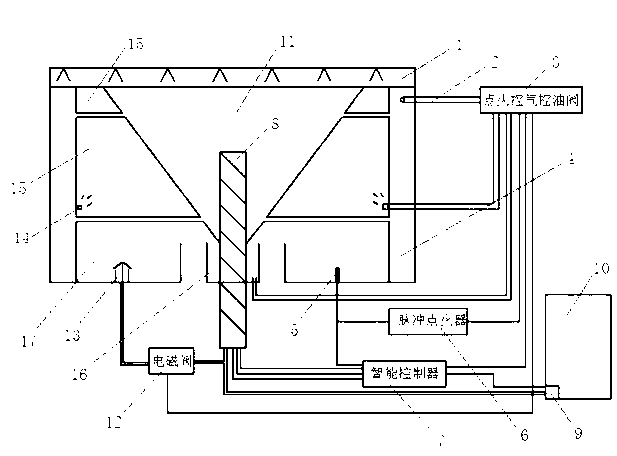

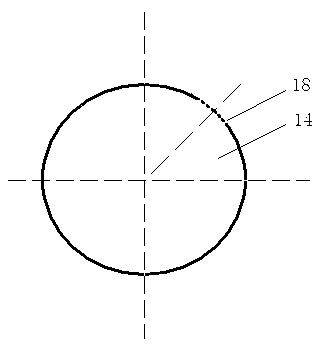

Embodiment 1

[0022] As mentioned above in the intelligent gasification furnace, the annular gas injection port 14 is provided with 8 gas injection holes 18, and the gas injection holes 18 face upward at an angle of 30° with the vertical direction, and the size of the gas injection holes 18 is 1 mm; the inner side of the first gasification chamber 4 faces The upper position is provided with a circle of annular gas injection ports 14; the second gasification chamber 11 is a conical gasification chamber; the intelligent controller 7 includes a power supply, a main controller, a control circuit, a control switch and a detection circuit.

Embodiment 2

[0024] As mentioned above in the intelligent gasification furnace, the annular air injection port 14 is provided with 16 air injection holes 18, the air injection holes 18 face upward at an angle of 45° with the vertical direction, and the size of the air injection holes 18 is 0.8mm; the inner surface of the first gasification chamber 4 A ring-shaped gas injection port 14 is arranged on the upward position; the second gasification chamber 11 is a conical gasification chamber; the intelligent controller 7 includes a power supply, a main controller, a control circuit, a control switch and a detection circuit.

Embodiment 3

[0026] As mentioned above in the intelligent gasification furnace, the annular gas injection port 14 is provided with 20 gas injection holes 18, the gas injection holes 18 face upward at an angle of 60° with the vertical direction, and the size of the gas injection holes 18 is 0.5mm; the inner surface of the first gasification chamber 4 A ring-shaped gas injection port 14 is arranged on the upward position; the second gasification chamber 11 is a conical gasification chamber; the intelligent controller 7 includes a power supply, a main controller, a control circuit, a control switch and a detection circuit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com