Ball feeder control system based on DCS system platform

A technology of DCS system and control system, applied in general control system, program control, comprehensive factory control, etc., can solve problems such as high investment, unaffordable, hidden safety risks, etc., to reduce labor costs, improve efficiency, and improve safety The effect of the production index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

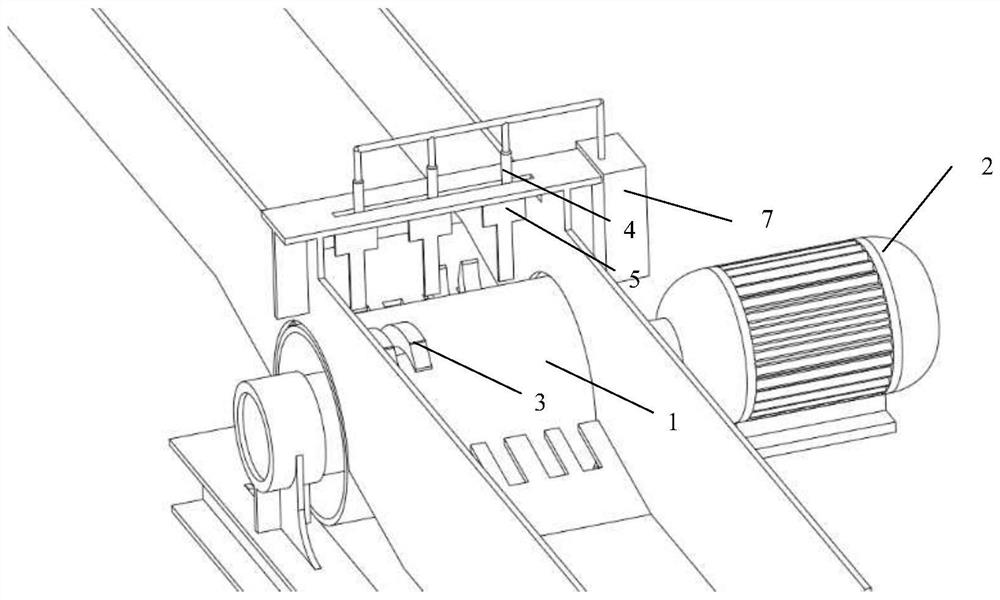

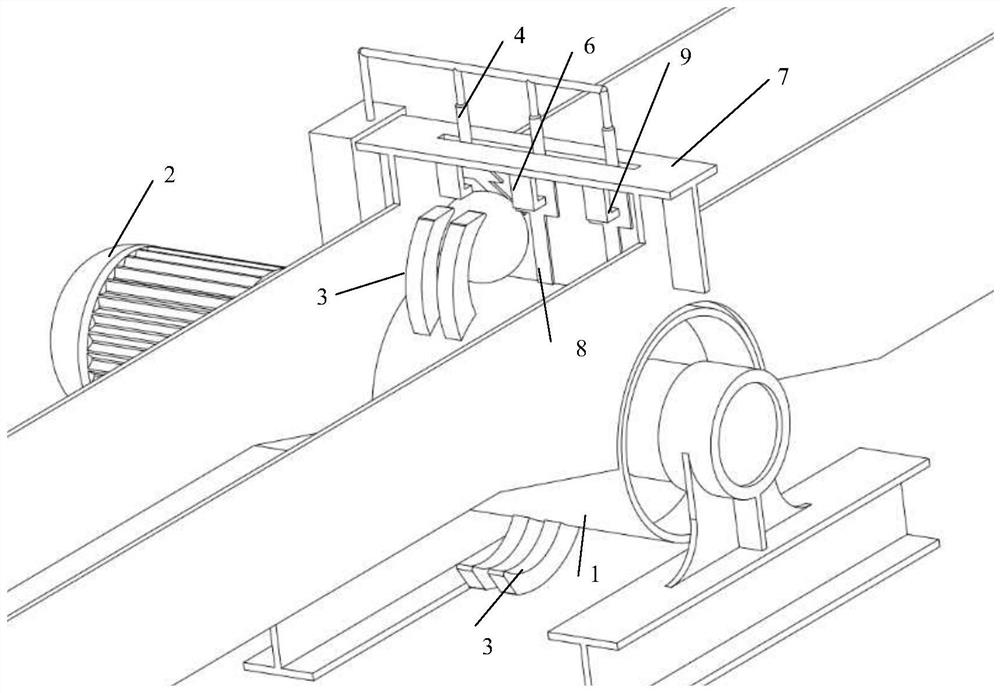

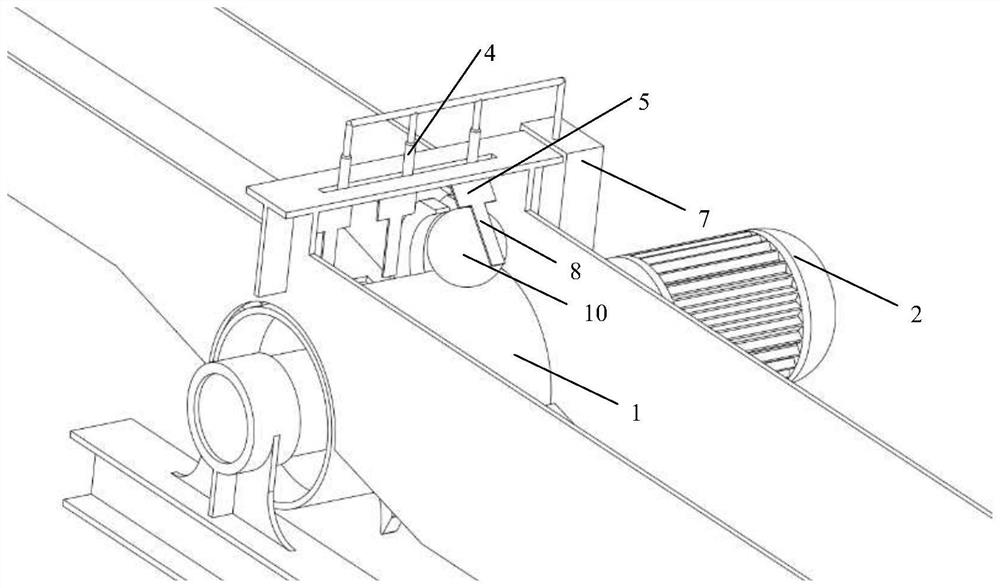

Image

Examples

Embodiment 1

[0034] Embodiment 1: the ball adding machine control system based on the DCS system platform, based on the DCS system built by the PKS of the mining and selection process control system Honeywell, a new control strategy CM is built on its system (CM is each C300 control station of the PKS system The abbreviation of each control strategy) realizes related process detection and control.

[0035] The advantage of Honeywell's DCS system platform is the detection and processing of analog quantities, while the motion logic control lags behind PLC. It has no logic language, and the processing speed of the controller is much lower than that of PLC. For the control strategy environment of the ball adding machine under the DCS controller, the scanning speed is increased, and the external digital input signal is set for 1S high-level clamping. In addition, the control strategy of other production links of the controller remains the same. This not only meets the needs of fast motion detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com