Large-scale mill process control system

A process control system and control system technology, applied in the field of mining machinery, can solve the problems of frequent shutdown, unscientific design of lubrication control system, distorted signal interference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

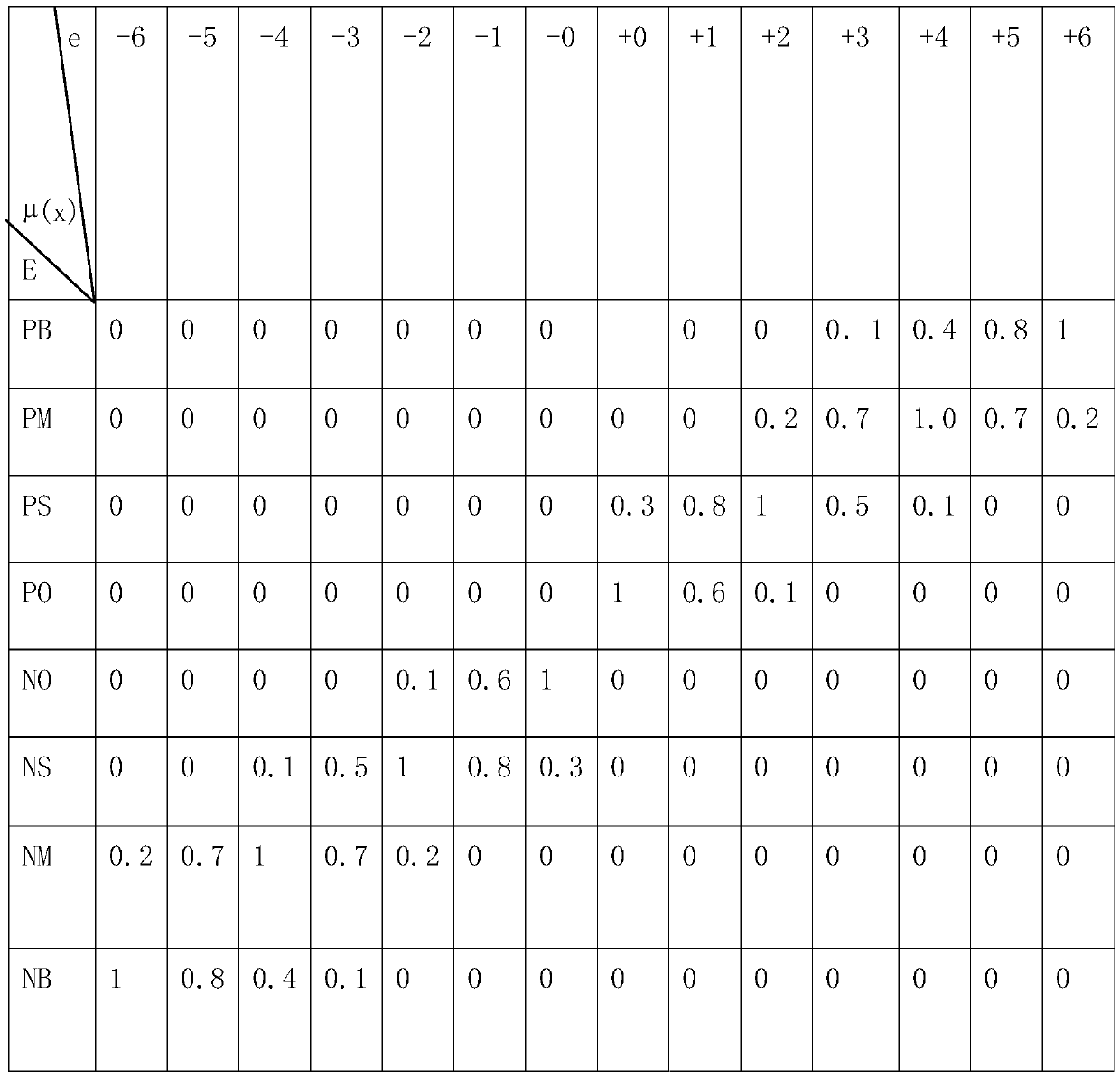

Method used

Image

Examples

Embodiment 1

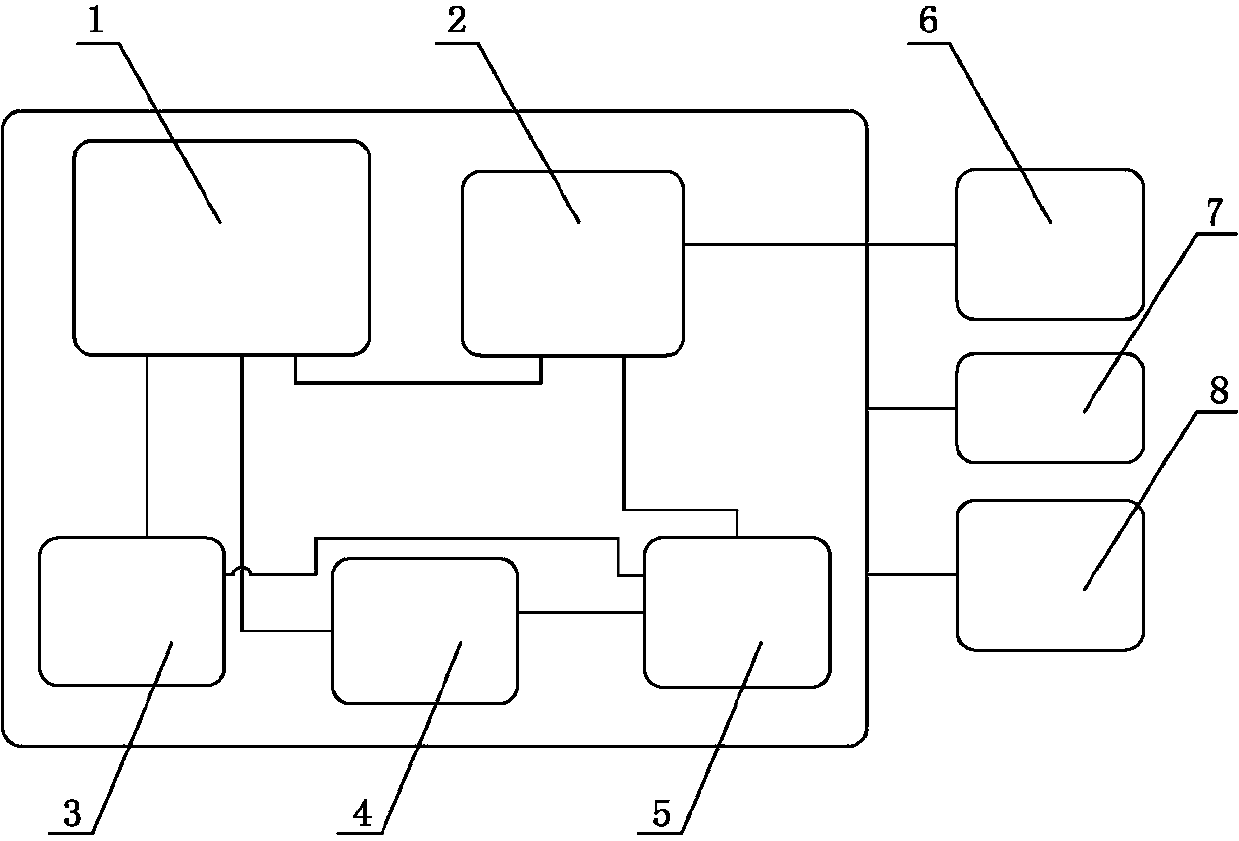

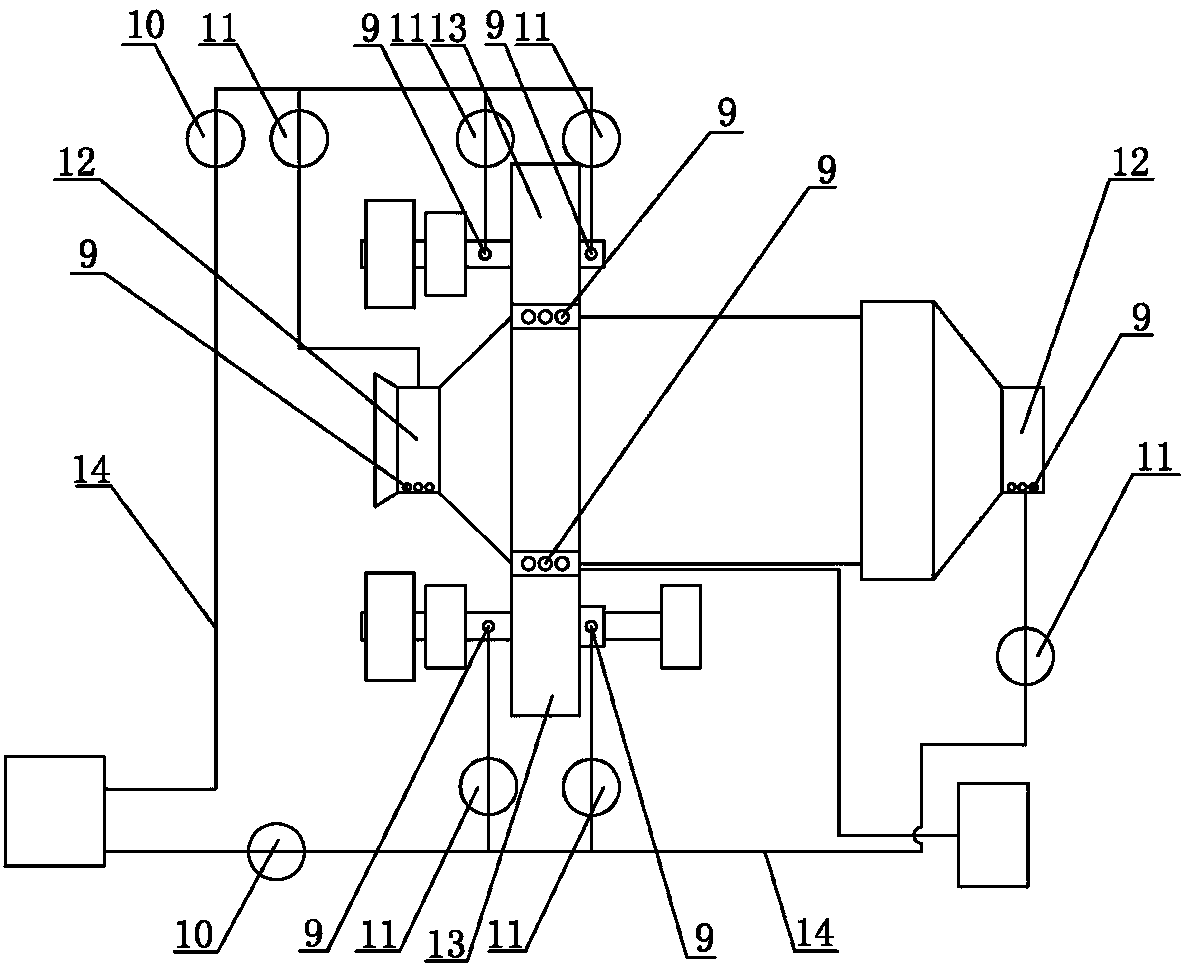

[0159] Embodiment 1: A large-scale mill process control system installed on the mill, the control system includes an internal framework, an external auxiliary unit and a mill monitoring system, the internal framework, the external auxiliary unit and the mill monitoring system are connected by wires, wherein :

[0160] The internal structure includes a logical interlocking control unit 1, an operating status monitoring unit 2, a screening control processing unit 3, a predictive control processing unit 4, a data history storage unit 5, and an online fault processing unit 6. The screening control processing unit 3 and the logical interlocking control unit are respectively 1. The data history storage unit 5 is connected, and the predictive control processing unit 4 is connected with the logic chain control unit 1 and the data history storage unit 5 respectively, and the logic chain control unit 1 and the data history storage unit 5 are respectively connected with the operation stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com