Construction system and method of factory type large aqueduct

A construction method and technology of aqueducts, which are applied in water conservancy projects, artificial waterways, buildings, etc., and can solve the problems of large aqueducts, complex structures, and high construction precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

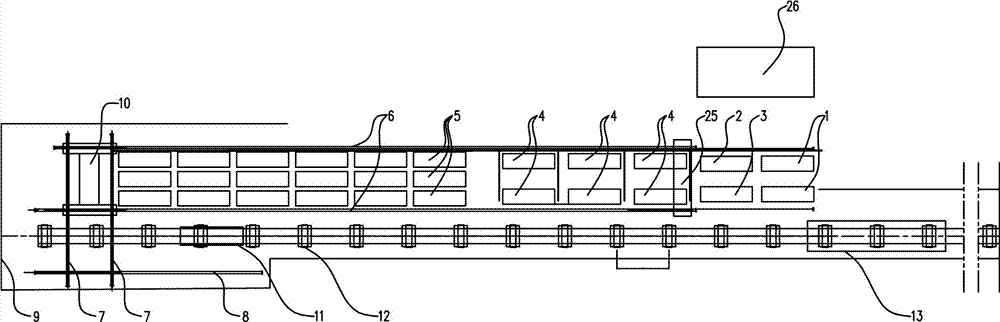

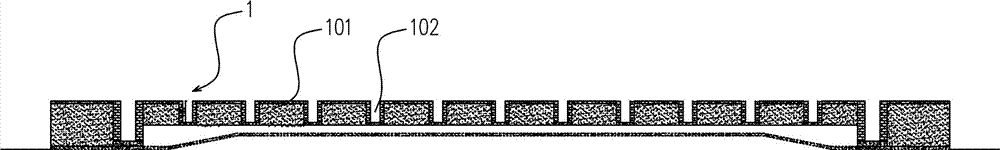

[0057] A factory-style large-scale aqueduct construction system. A steel bar pedestal 1, a steel bar spreader storage area 2, a steam shed storage area 3, a trough making pedestal 4, and a trough storage pedestal 5 are set near the trough pier 12; wherein the steel bar pedestal 1, the manufacturing There are multiple groove pedestals 4 and storage groove pedestals 5.

[0058] In this example, from the position close to the end of the trough pier 12 to the position away from the end of the trough pier 12, 18 storage pedestals 5 are arranged in sequence, arranged in 3 rows×6 columns, and there are 46 trough-making pedestals, arranged by 2 Arranged in rows × 3 columns, one steel bar spreader storage area 2 and one steam shed storage area 3, arranged side by side, and two steel bar pedestals, arranged in 2 rows × 1 column.

[0059] The groove piers 12 here refer to a linear overall structure composed of a plurality of groove piers 12 .

[0060] Rails are arranged near the steel b...

Embodiment 2

[0079] Such as Figure 1~7 Among them, a kind of construction method that adopts above-mentioned factory type large-scale aqueduct construction system comprises the following steps:

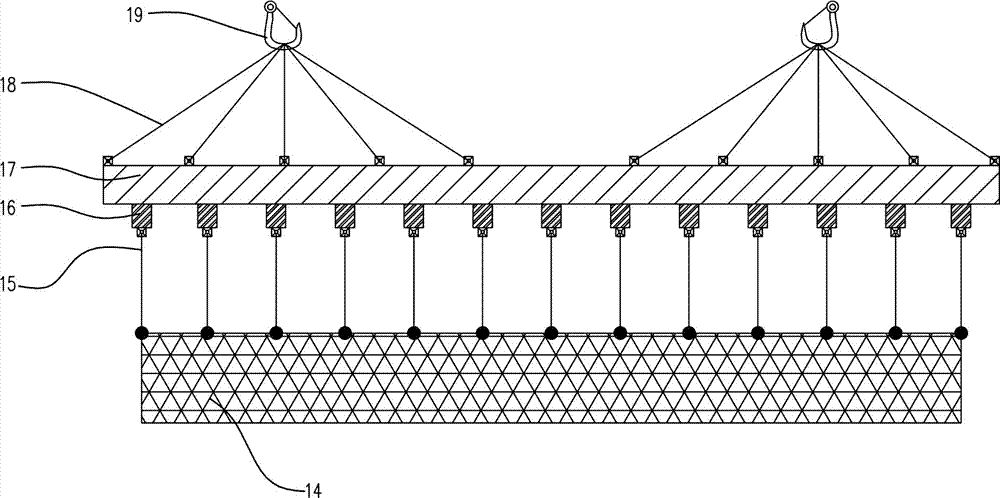

[0080] s1, the reinforcement cage 14 of the aqueduct integrally bound on the reinforcement pedestal 1;

[0081] First install the side wall reinforcement support frame of the tank body. The support frame is arranged along both sides of the main beam and connected by steel pipes and fasteners to improve the installation accuracy and deformation resistance of the side wall reinforcement;

[0082] The secondary beam reinforcement is installed on the top surface of the installation stand in order to install the secondary beam reinforcement from the middle to both ends. The installation sequence of the secondary beam reinforcement is the bottom reinforcement, the stirrup, the side reinforcement, the top reinforcement, and finally the stirrup binding;

[0083] For the installation of the main beam rei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com