Grouting reinforcement construction method for foundation bottom disengaging

A technique of grouting reinforcement and foundation bottom, which is applied in foundation structure engineering, foundation structure repair, construction, etc. It can solve the problems of the bottom surface of the foundation being empty, unable to tamp, poor silt and soil conditions, etc., to achieve improved grouting effect, Avoid cross operation, the effect of grouting effect is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

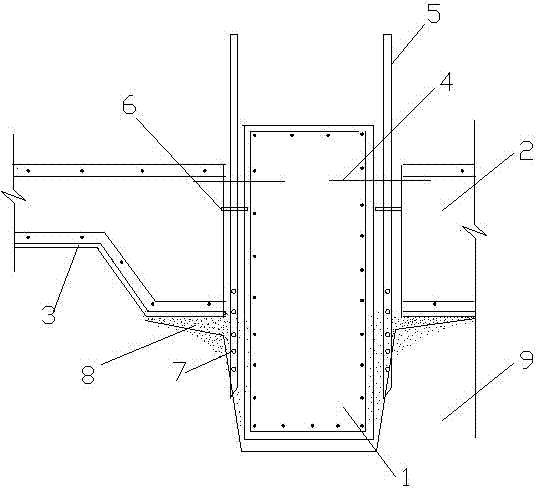

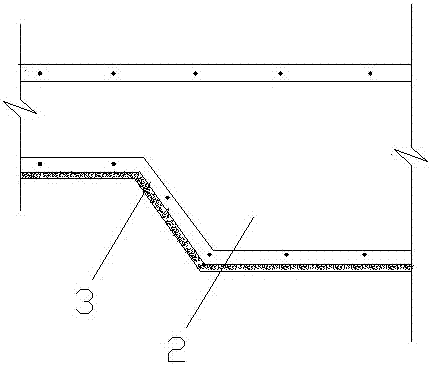

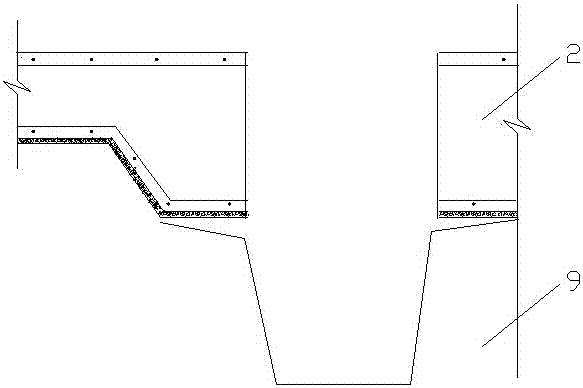

[0041] The present invention is described in detail below with reference to accompanying drawing and embodiment:

[0042] attached Figure 1-5 It can be seen that

[0043] A grouting reinforcement construction method for foundation bottom voiding,

[0044] Step 1: According to the requirements of the design drawings and construction specifications, measure and release the base line, and then release the size that needs to be chiseled and removed on the original foundation;

[0045] Step 2: Use a grinding wheel or a toothless saw to cut the surface of the foundation according to the size of the wire, and use a mechanical hydraulic pick (hydraulic hammer or pneumatic pick) to remove the foundation for protection; whether to retain the inner reinforcement of the foundation according to the design requirements, if not, use it Cut off directly by gas welding, manually clean and remove the foundation surface and construction waste in the foundation pit;

[0046] The third step: a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com