Electrolytic aluminum anode scrap cleaning and crushing system and recovery method

A crushing system and electrolytic aluminum technology, applied in the field of electrolytic aluminum residue cleaning and crushing system and recycling, can solve the problems of high equipment operation cost, high labor intensity, and high vehicle transportation cost, so as to reduce losses, avoid cross operations, and save money. The effect of equipment investment and equipment operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to facilitate those skilled in the art to better understand the present invention, the present invention will be further described below in conjunction with specific examples.

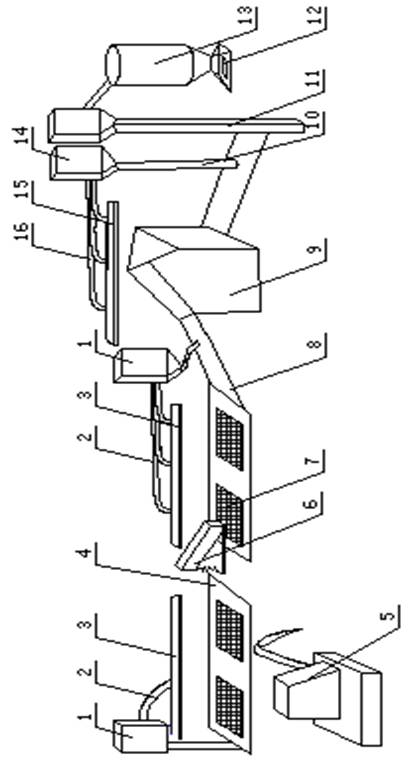

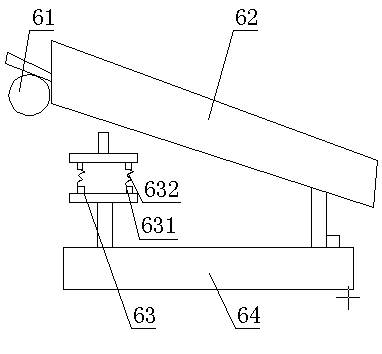

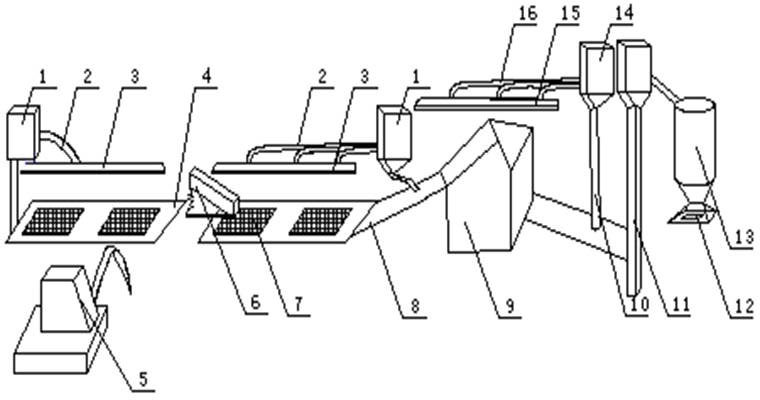

[0026] Reference attached figure 1 , an electrolytic aluminum residue cleaning and crushing system, including two cleaning platforms 4, a demolition crusher, a large-angle belt conveyor 8, an impact crusher 9 and a material bin 13; the surface of the cleaning platform 4 is provided with A plurality of grilles 7, the demolition of the crusher is an excavator with a crusher located on the cleaning platform 4; part of the large-inclination belt conveyor 8 is set under the cleaning platform 4, and the other part extends out of the cleaning platform 4, and the end point is higher than the cleaning platform 4. The cleaning platform 4; the entrance of the impact crusher 9 is connected to the end point of the belt conveyor 8 with a large inclination angle, and the exit of the impact crusher 9 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com