Multi-pipeline fixed support and construction method thereof

A fixed bracket and pipeline fixing technology, which is applied in the direction of pipeline support, pipeline protection, pipeline protection through heat insulation, etc., can solve the problems that affect the quality of the overall pipeline installation, multiple pipelines are arranged side by side, and the operation of pipeline fixing brackets is complicated. , to achieve the effect of increasing the types of feasibility, simplifying the construction process, and setting a high height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

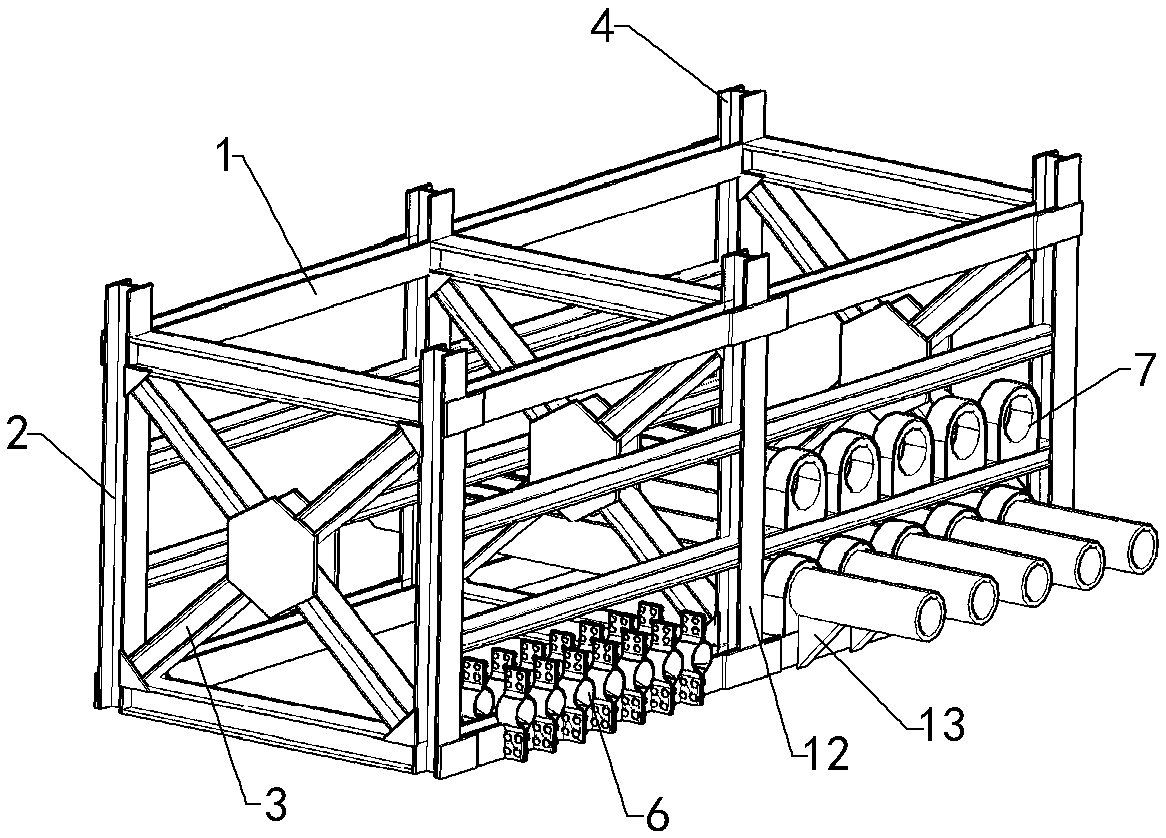

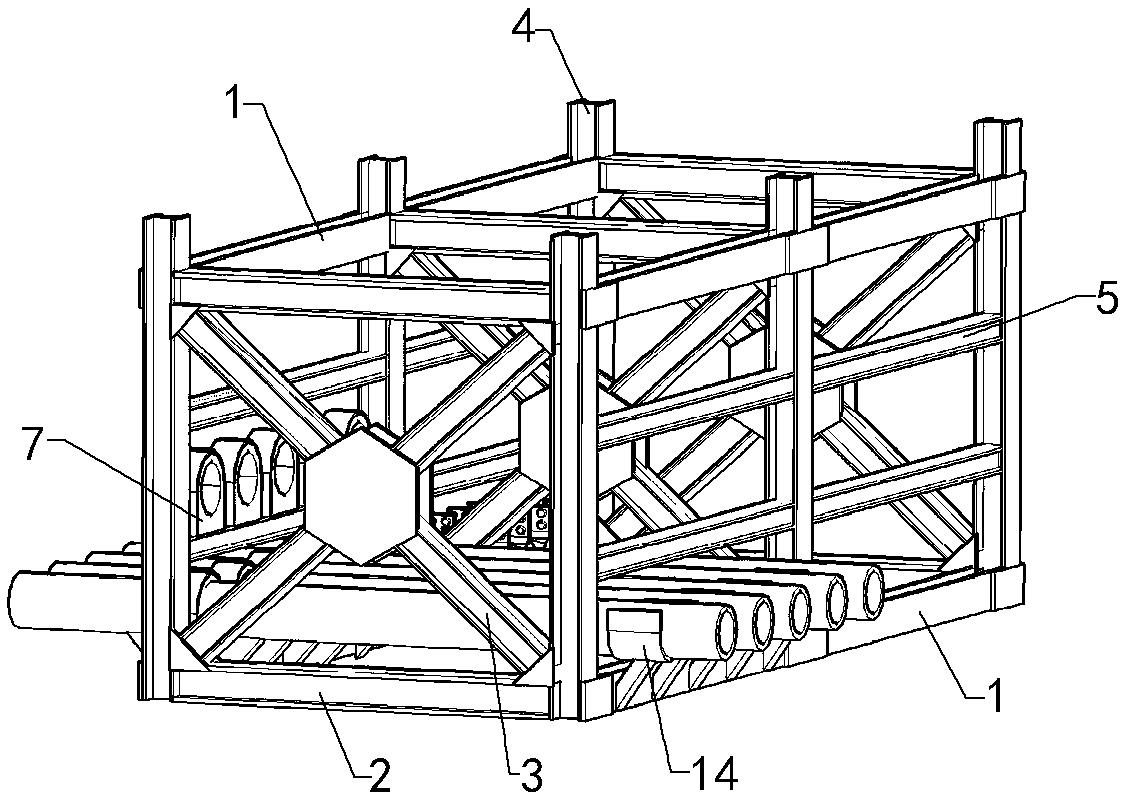

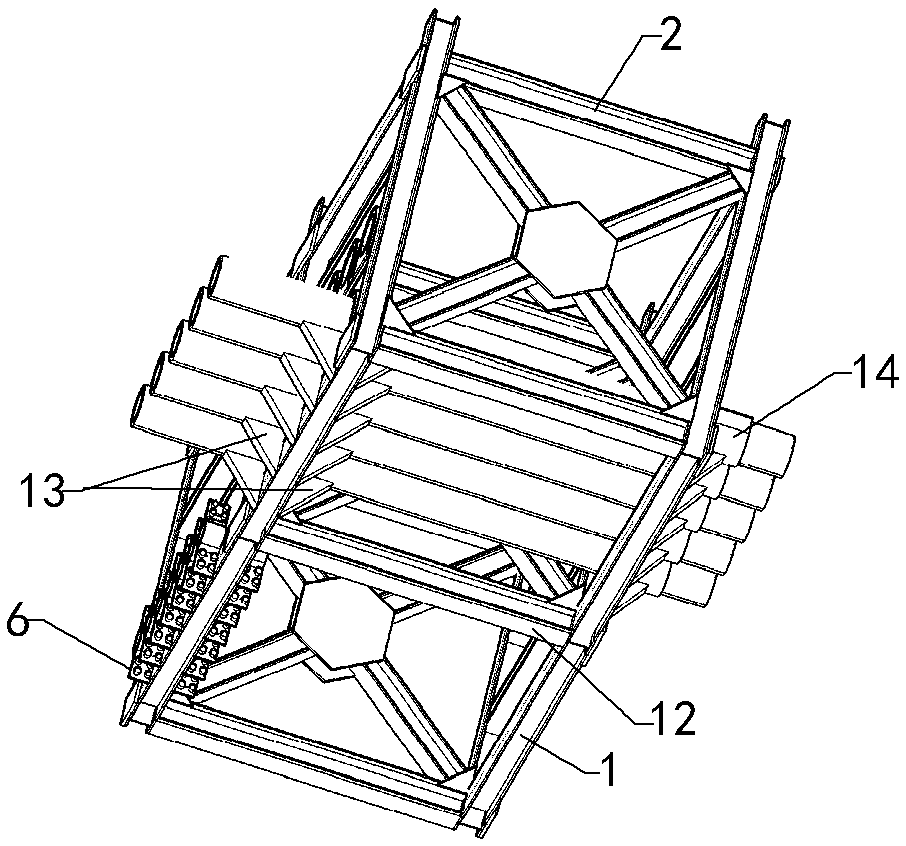

[0041] Such as Figure 1-Figure 7As shown, the multi-pipe fixed bracket of the present invention, the fixed bracket is a cuboid frame structure, which is surrounded by four horizontal beams 1 arranged parallel to each other and the square reinforcement frame 2 at both ends of the horizontal beam 1, and the height of the square reinforcement frame 2 is not greater than 5m, two diagonal brace beams 3 are welded on each of the two opposite corners of the square reinforcement frame 2, and the two brace beams 3 are arranged in an X shape. The connecting part 4 connected to the rear embedded parts in the inner part is provided with a cross arm 5 between the upper and lower adjacent horizontal beams 1, the cross arm 5 and the horizontal beam 1 are parallel to each other, the pipe is perpendicular to the horizontal beam 1, and passes through the fixed bracket horizontally , the two side facades of the fixed bracket through which the pipeline passes are the fixed surface and the guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com