Mining technology for inclined orebodies in opencast mines

A technology of ore body and technology, which is applied in the field of mining technology of inclined ore bodies in open-pit mines, can solve the problems of waste of ore resources, raw ore grade, indiscriminate ore and surrounding rock waste rock, and surrounding rock mixed into ore, so as to reduce ore dilution The effect of improving efficiency, improving work efficiency, and smooth production operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

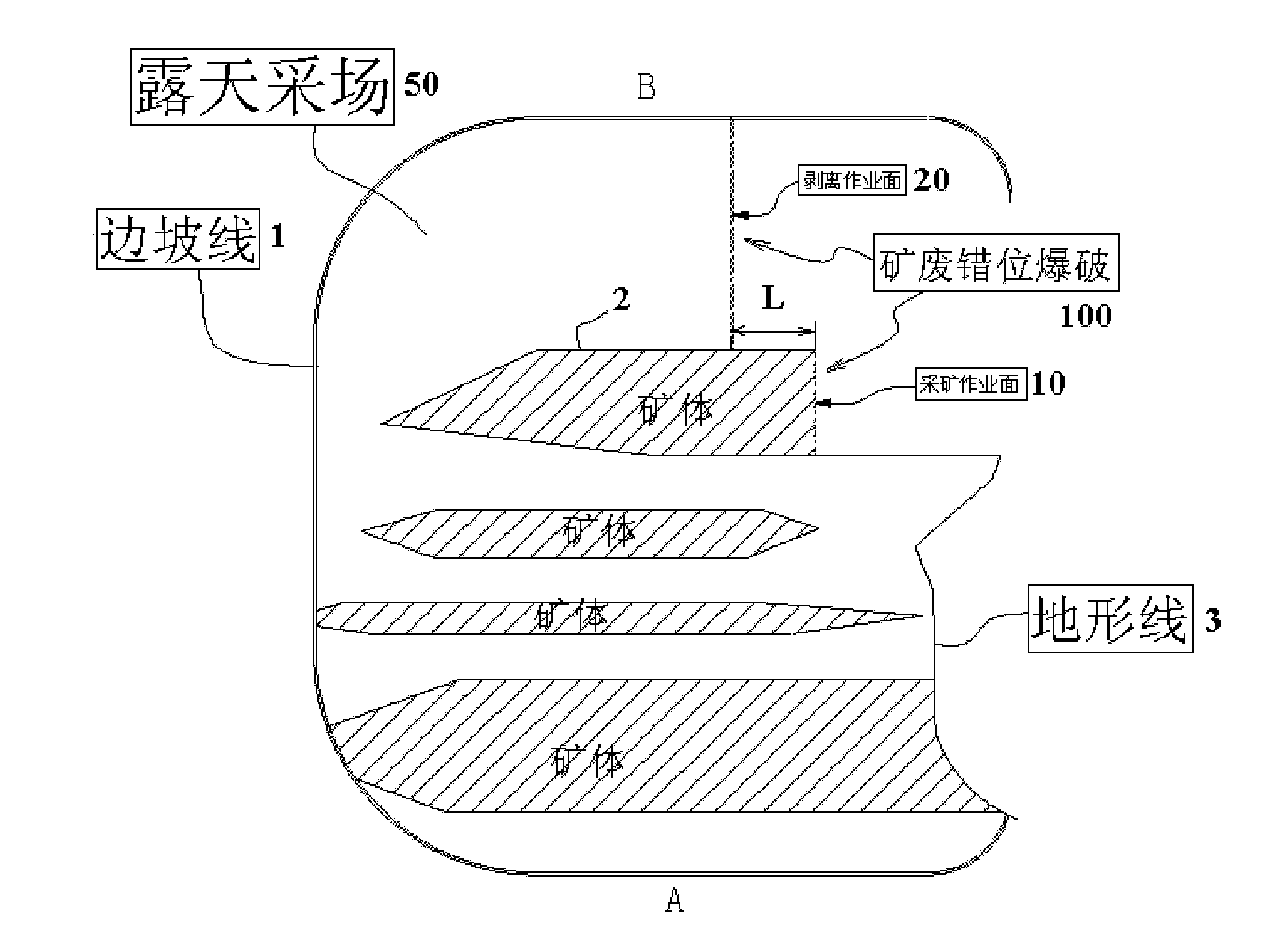

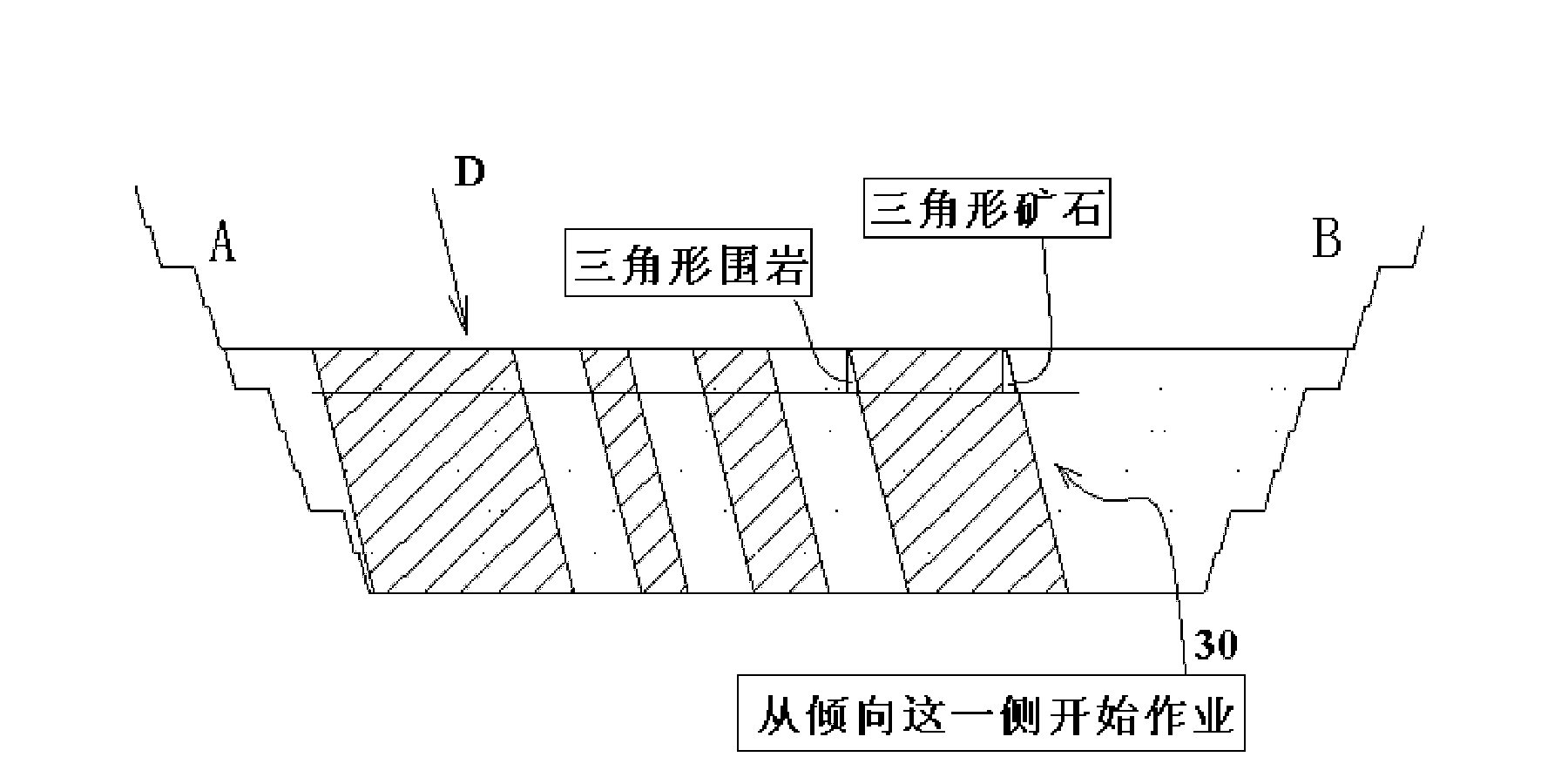

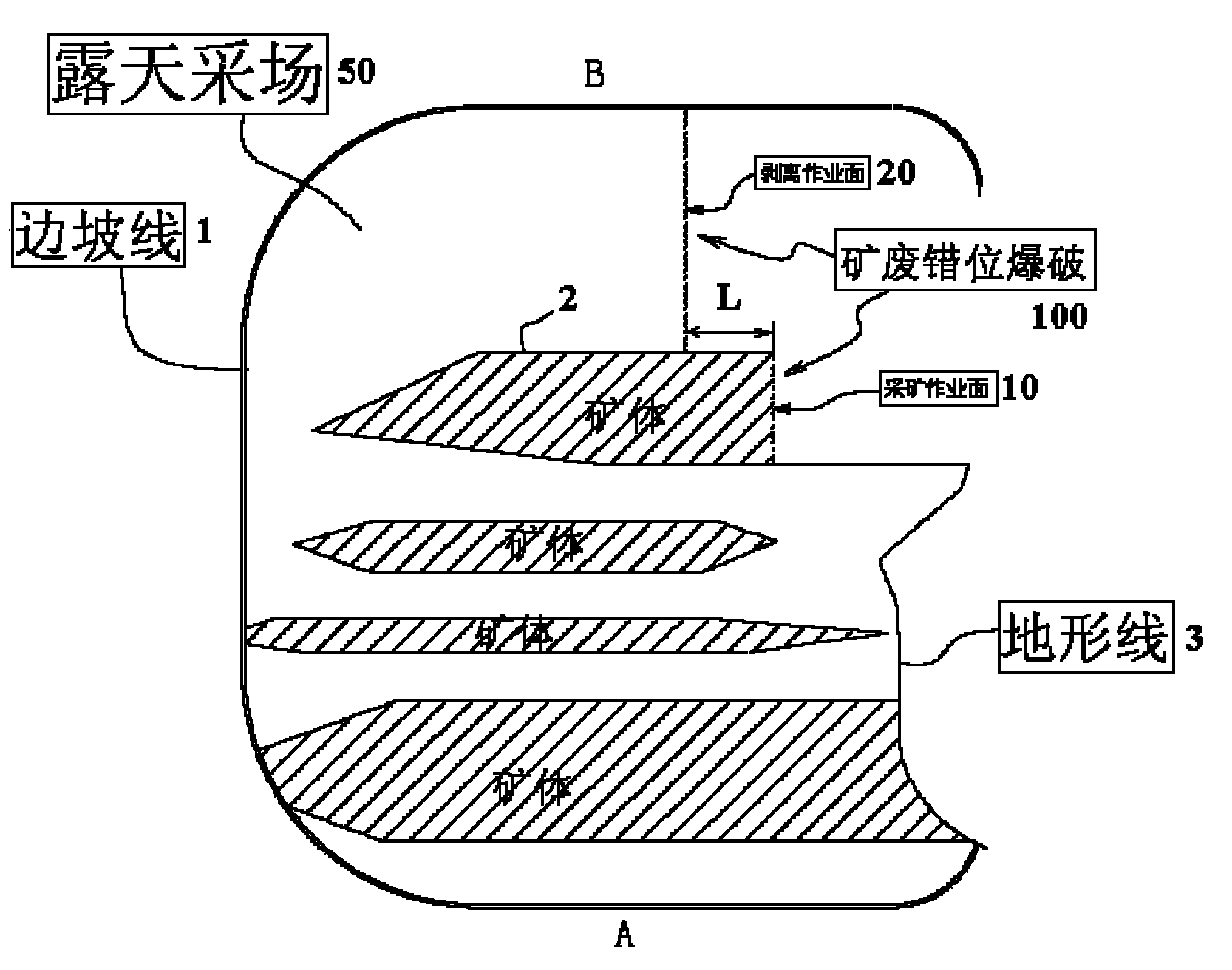

[0014] Such as Figure 1-2 As shown, the open pit 50 surrounded by the slope line 1 and the terrain line 3 has an A side and a B side. The open pit 50 has a series of inclined orebodies 2 . The present invention alternately processes the stripping operation face 20 and the mining operation face 10 in the manner of mine waste dislocation blasting 100 . figure 1 It means that the surrounding rock on the left side is stripped first 20, and then the ore is mined 10, and the dislocation distance L between the mining and the stripping operation face is not less than 28 meters. figure 2 Indicates the part where the vertical blast hole will increase the ore dilution rate and loss rate; at the same time, it also intuitively reflects the reason why the inclined hole cannot be operated from the A side. Because the operation of less than 90° is "digging" inward, it will directly increase the ore dilution rate and loss rate.

[0015] According to the rock drilling blasthole technical s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com