Pile cap for single pile bearing capacity detection of CFG pile and using method thereof

A technology of bearing capacity and single pile, which is applied in the test of sheet pile wall, foundation structure, construction, etc., can solve the problems of long detection period, inconvenience, and influence on the construction period, and achieve the goal of simple structure, low price, and reduced construction cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The pile cap used for testing the bearing capacity of a single pile of a CFG pile according to the invention is used for bearing a CFG pile whose bearing capacity of a single pile is ≤ 1000KN, and includes a steel casing and a steel plate.

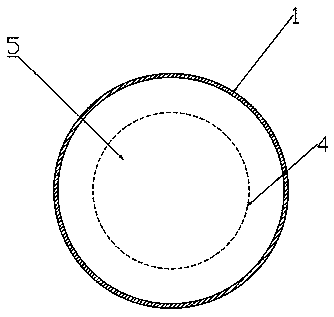

[0036] see now figure 1 , figure 1 It is a structural schematic diagram of a pile cap according to an embodiment of the present invention. As shown in the figure, the steel casing is a circular hollow steel pipe matching the shape of the end of the CFG pile. The steel pipe can be placed on the end of the CFG pile to form a pile cap; Sand, the fine sand inside the steel pipe is close to the outside of the CFG pile end.

[0037] The steel plate is a circular steel plate.

[0038] Wherein: a round steel plate is placed in the center of the fine sand top of the upper opening of the steel pipe. The material of the steel pipe is a 10mm thick steel plate. The distance between the inner wall 2 around the steel pipe and the outer side o...

Embodiment 2

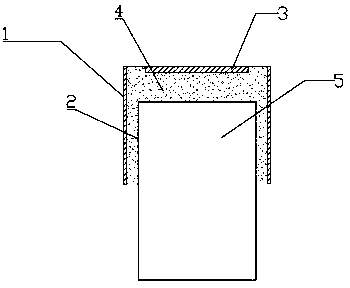

[0040] figure 2 It is a schematic diagram of the use state of the pile cap of the embodiment of the present invention. The using method of the pile cap that is used for the single pile bearing capacity detection of CFG pile of the present invention may further comprise the steps:

[0041] a. The CFG pile to be tested is cut off;

[0042] b. The steel pipe is placed at the end of the CFG pile;

[0043] c. Fill the contact part between the steel pipe and the CFG pile with fine sand, place a 20mm thick steel plate in the center on the top of the fine sand, and the distance between the steel plate and the pile top is 50~100mm;

[0044] d. Check the verticality of the steel pipe and the flatness of the fine sand on the top of the steel pipe and the flatness of the steel plate, set up the testing equipment and start the pile inspection.

[0045] 8. The method of using a pile cap for single pile bearing capacity detection of a CFG pile as claimed in claim 1, wherein the steel pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com