Combined prefabricated bridge guardrail

A combined and guardrail technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of unsightly viaducts and the influence of exterior façade modeling, and achieve the effect of saving the total construction period, convenient construction, and easy guarantee of appearance quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

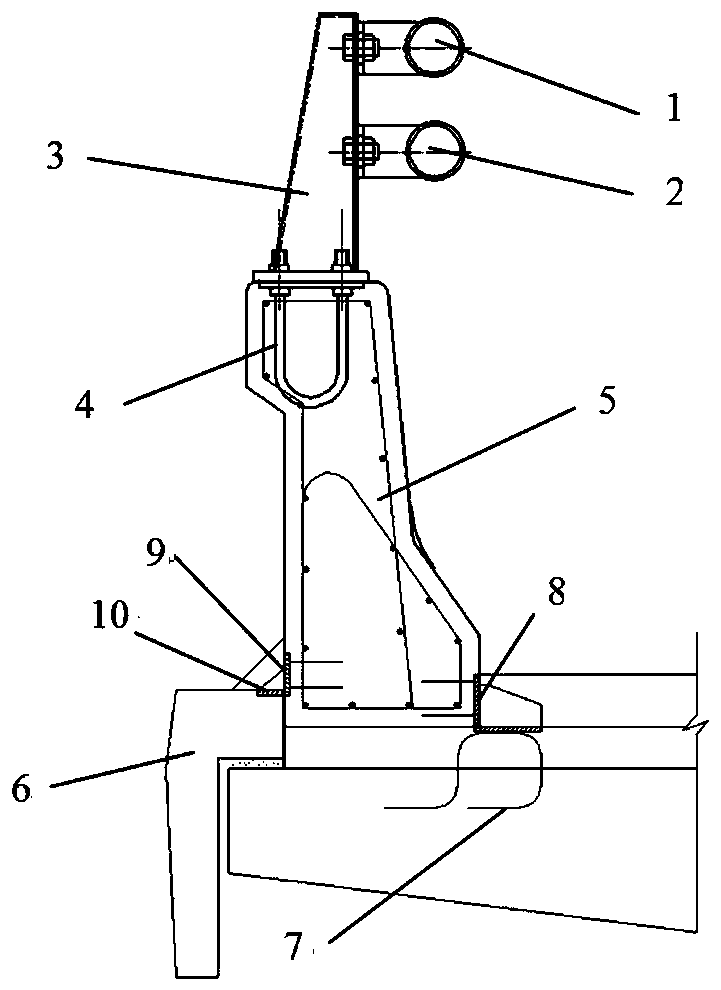

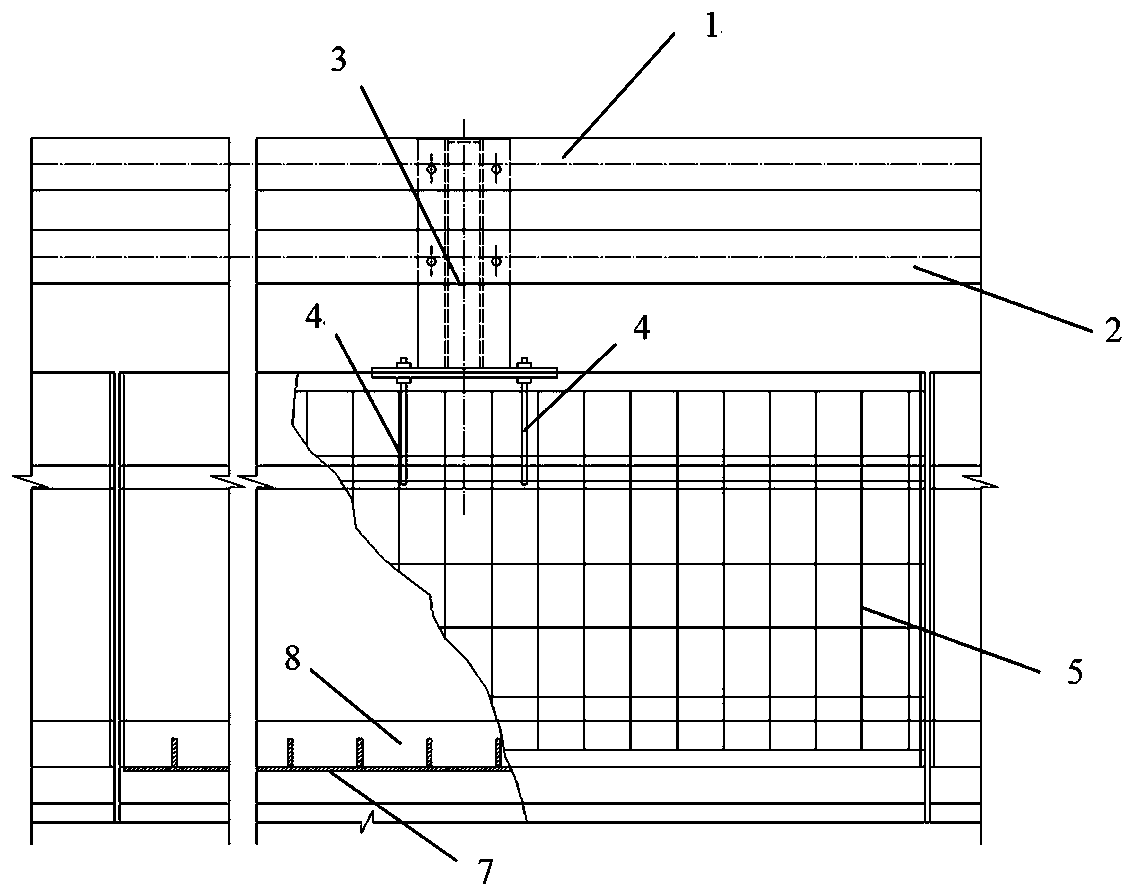

[0029] based on the following Figure 1 ~ Figure 3 , specifically explain the preferred embodiment of the present invention.

[0030] Such as Figure 1 ~ Figure 3 As shown, the present invention provides a prefabricated bridge prefabricated anti-collision barrier for on-site installation, comprising:

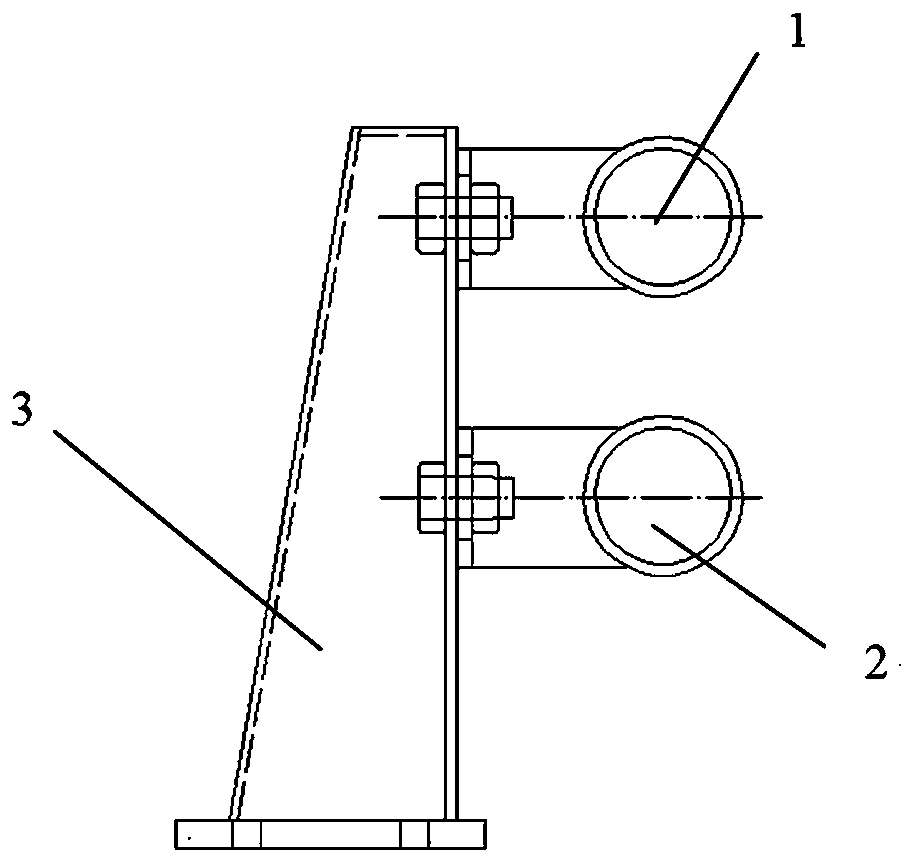

[0031] Steel pipe guardrail 1, the steel pipe guardrail includes an LED light strip to provide road lighting.

[0032] Steel anti-collision guardrail 2, the steel anti-collision guardrail adopts seamless steel pipe to play the role of anti-collision beam.

[0033] The steel column 3 is set in the middle of the anti-collision guardrail. Two steel pipe guardrails are fixed on the side of the steel column. The steel column includes a bracket and a base. , Use bolts to connect when installing steel structure columns.

[0034] U-shaped pre-embedded steel bars 4. When the concrete anti-collision wall is prefabricated, the U-shaped steel bars are pre-embedded, and the exposed wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com