Integral quick lifting method for pile head of drilled pile during pre-embedding and drilling-free ring-cutting

A technology that avoids drilling and bored piles. It is applied in excavation, sheet pile walls, construction, etc. It can solve the problems of high-efficiency construction speed mismatch, large damage to pile body reinforcement, and labor and material resources consumption, so as to achieve economical and reasonable construction investment. , Short construction period and fast construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

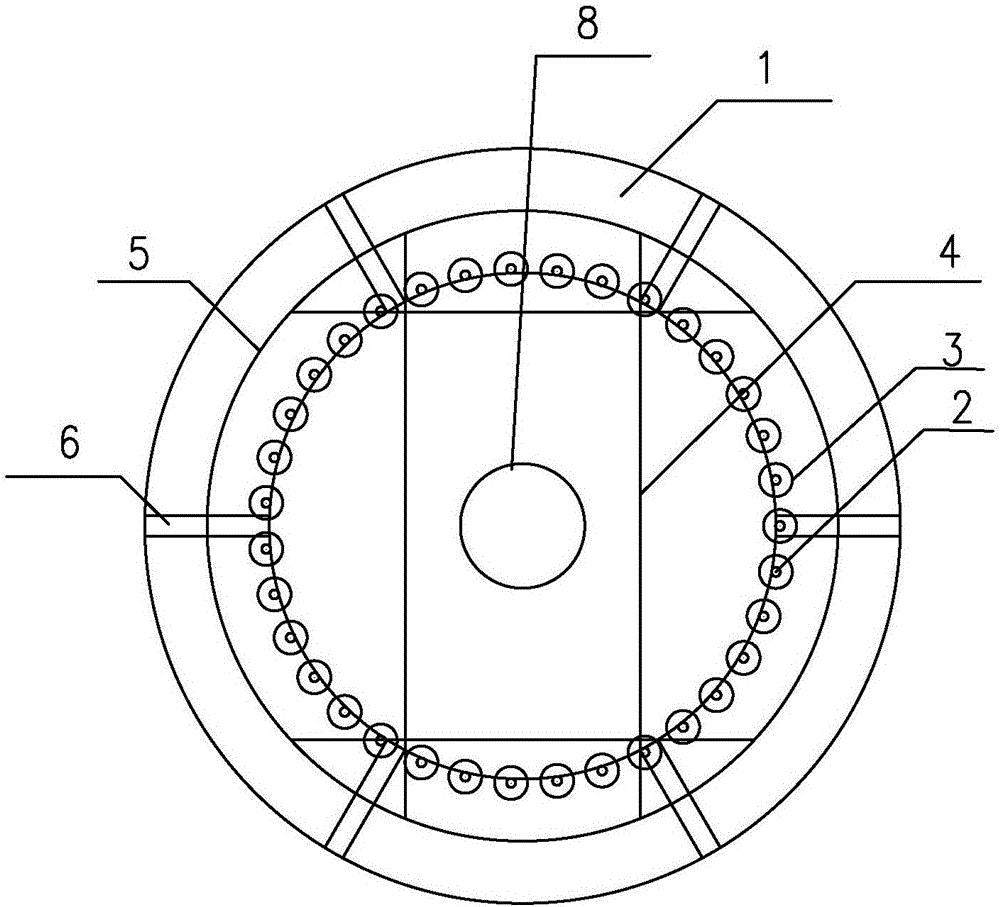

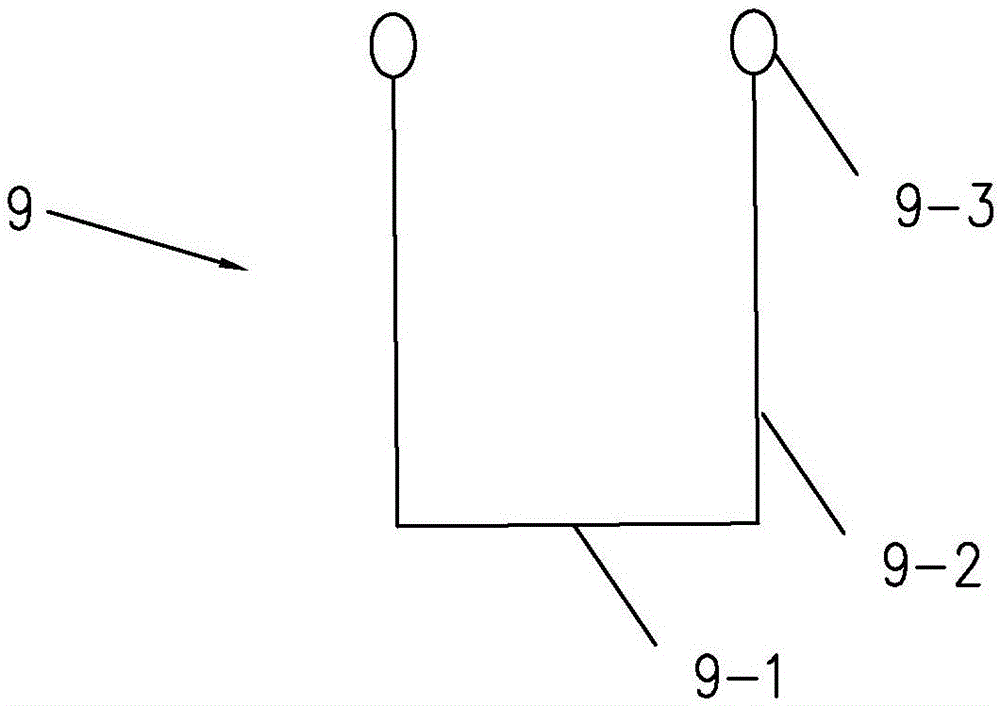

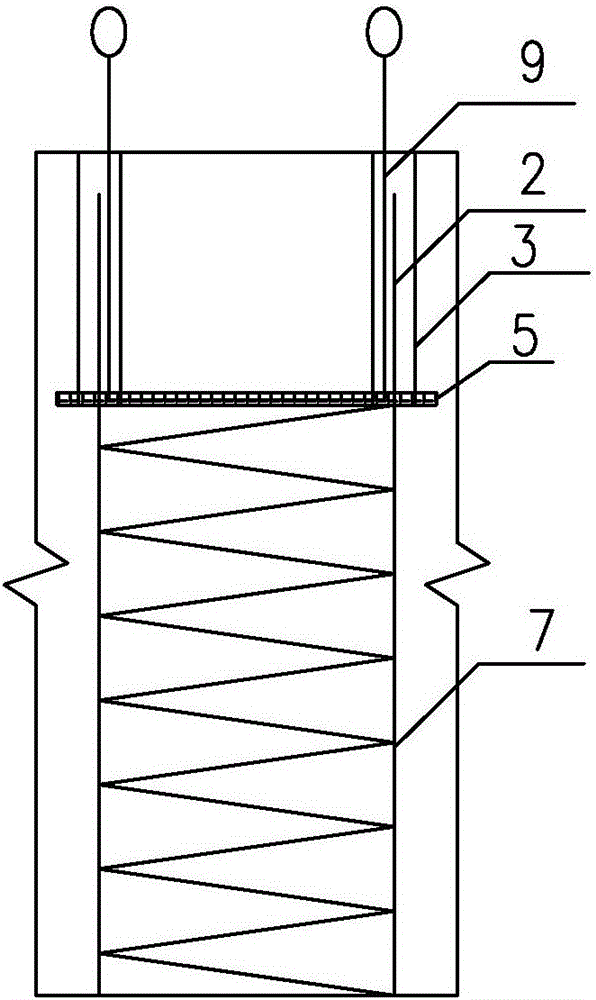

[0041] see Figure 1 to Figure 5 , a method for pre-embedded pile heads of bored piles without drilling circumcision and overall quick lifting, which adopts the following lifting device, and the device includes:

[0042] A plurality of foam sponge pipes 3 are used to wrap the main reinforcement 2 of the pile head and the acoustic measuring pipe to protect the steel cage. The tail part should wrap the tail of the main reinforcement, and use rubber bands to fix and seal the head and tail of the pipe mouth with wide tape, and ensure that the pile is broken after pouring When the head is not wrapped by concrete, as a preferred option, the foam sponge tube 3 is selected with an inner diameter of Ф55mm and an outer diameter of Ф85mm, and a thickness of 15mm. High-quality high-strength PVC sponge foam tube has strong elasticity and can ensure that it will not be crushed by concrete during pouring;

[0043] Annular positioning ring 5, the diameter of which is greater than the diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com