Three-hole highway tunnel and middle drift TBM-double main hole drilling and blasting joint construction method

A technology for highway tunnels and construction methods, applied in tunnels, earth-moving drilling, mining equipment, etc., can solve the problems of high pressure on material organization, slow construction progress, and long construction period, so as to reduce the pressure on material organization and reduce the pressure on material organization. , The effect of low investment in personnel and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

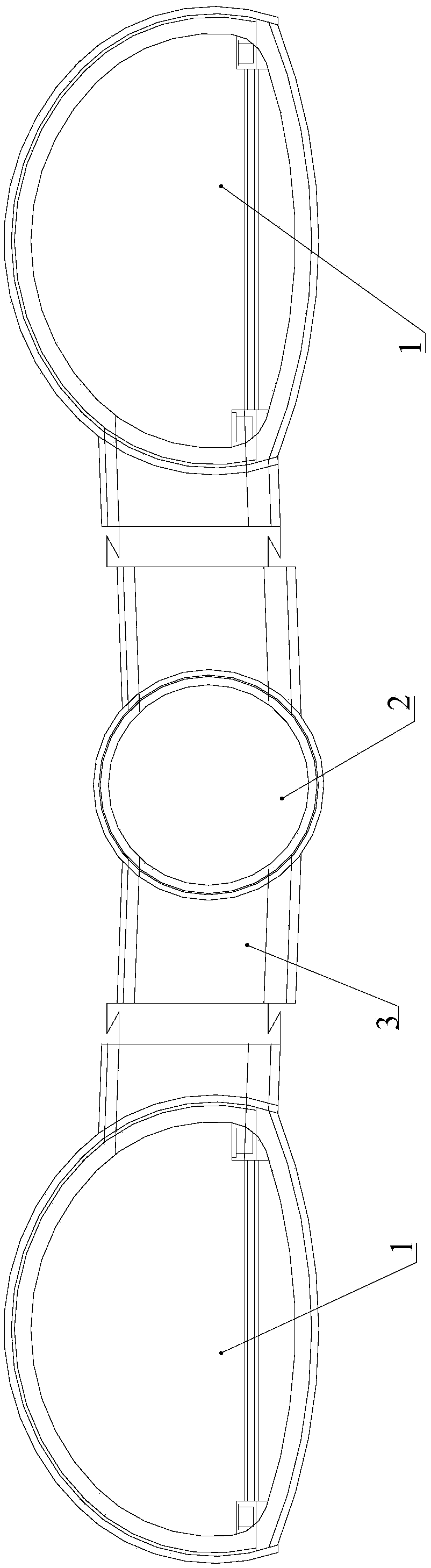

[0037] Such as figure 1 As shown, a three-hole road tunnel includes two main holes 1, and a middle pilot hole 2 is provided between the two main holes 1, and the middle pilot hole 2 is connected to the two main holes 1 respectively. They are connected through several transverse tunnels 3 for vehicles, and the middle pilot tunnel 2 is a channel that at least satisfies one-way traffic. The main tunnel 1 is excavated by the drill and blast method, and the intermediate pilot tunnel 2 is excavated by the TBM method. Both the main tunnel 1 and the intermediate pilot tunnel 2 are equipped with support, lining and drainage systems.

[0038] The middle pilot tunnel 2 is arranged along the longitudinal direction of the main tunnel 1, and the cross-sectional size of the middle pilot tunnel 2 is smaller than the cross-sectional size of the main tunnel 1. Through the set middle pilot tunnel 2 and the vehicle transverse tunnel 3, on the one hand, in the tunnel construction process Among th...

Embodiment 2

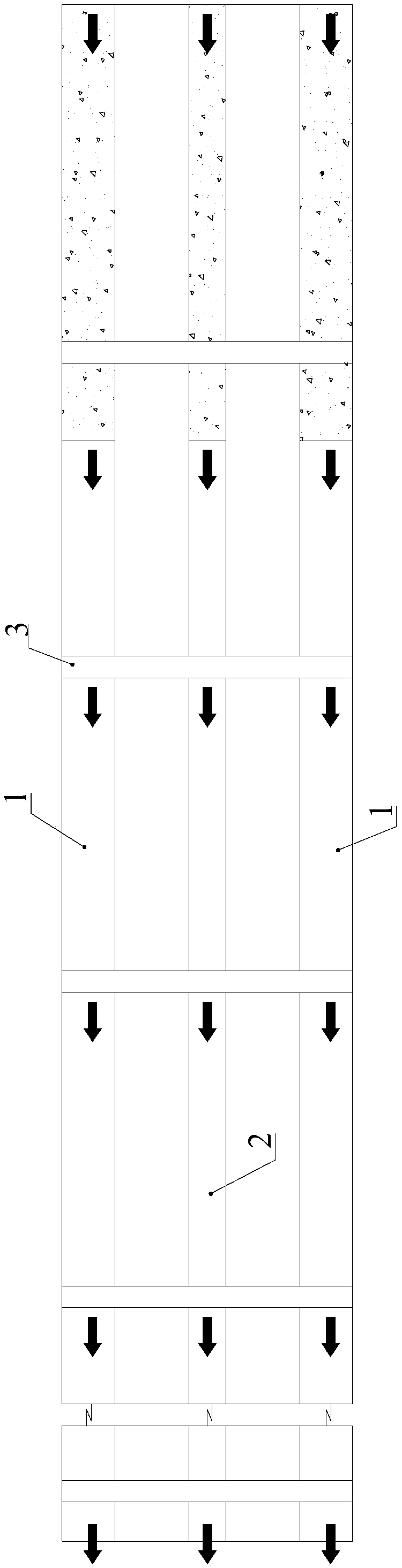

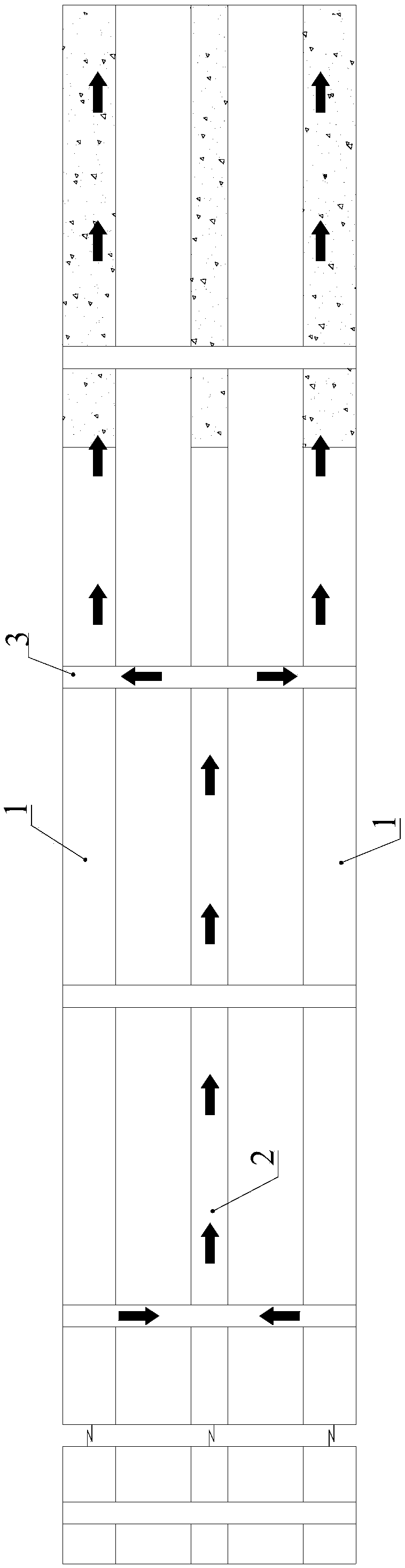

[0040] Such as Figure 1-Figure 3 Shown, a kind of middle pilot hole TBM-drilling and blasting joint construction method of double main hole, uses described a kind of three-hole highway tunnel, comprises the following steps:

[0041] Step 1: During TBM production, assembly, and commissioning, the opening sections of the main tunnel 1 and the intermediate pilot tunnel 2 are constructed using the drill and blast method, in which the intermediate pilot tunnel 2 goes first, and the two main tunnel 1 and the intermediate pilot tunnel 2 The working faces are misplaced, and the staggered distance between the two working faces is greater than twice the excavation width of the main hole 1 .

[0042]Step 2: After the TBM is assembled and debugged, the drilling and blasting construction of the intermediate pilot tunnel 2 is stopped, and the TBM advances to the working face of the intermediate pilot tunnel 2 to start TBM excavation, and the two main tunnels 1 continue to carry out the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com