Sublevel open subsequent filling stoping method

A filling mining method and open field technology, which is applied in the direction of filling, ground mining, mining equipment, etc., can solve problems such as potential safety hazards, and achieve the effects of reducing production costs and improving the construction environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

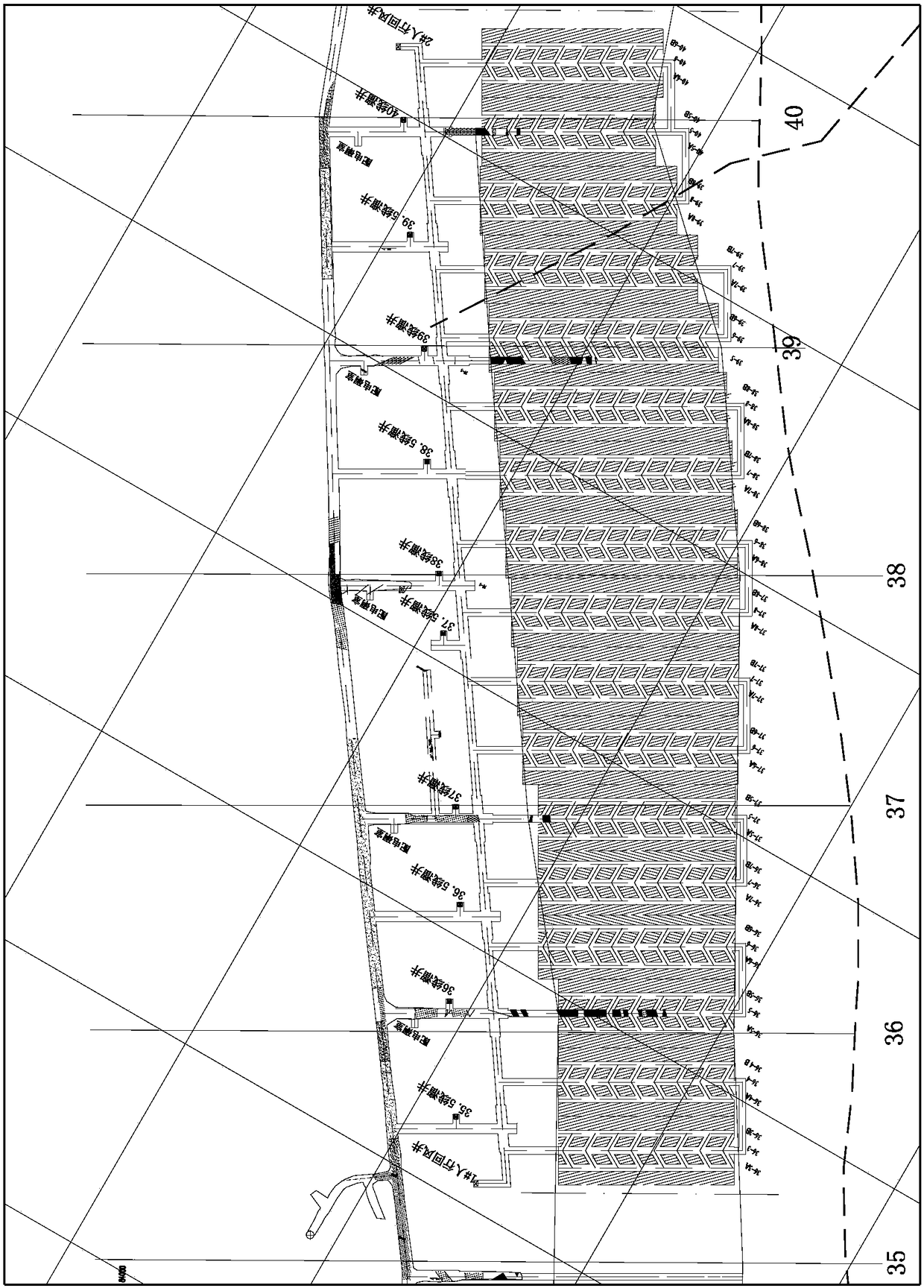

[0019] In this embodiment, the thickness of the ore body is large, and the thickness of No. 37 survey line is 65 meters; the dip angle of the ore body of No. 38 survey line is 67 degrees, and the thickness is 67 meters; The ore body is 59 degrees, and the thickness is 56 meters; the overall dip angle is between 45-60 degrees, and the thickness is 55-75 meters. The design adopts the mining method of segmental emptying and subsequent filling, rock drilling in segments, and ore extraction in stages. The specific implementation method and steps are as follows:

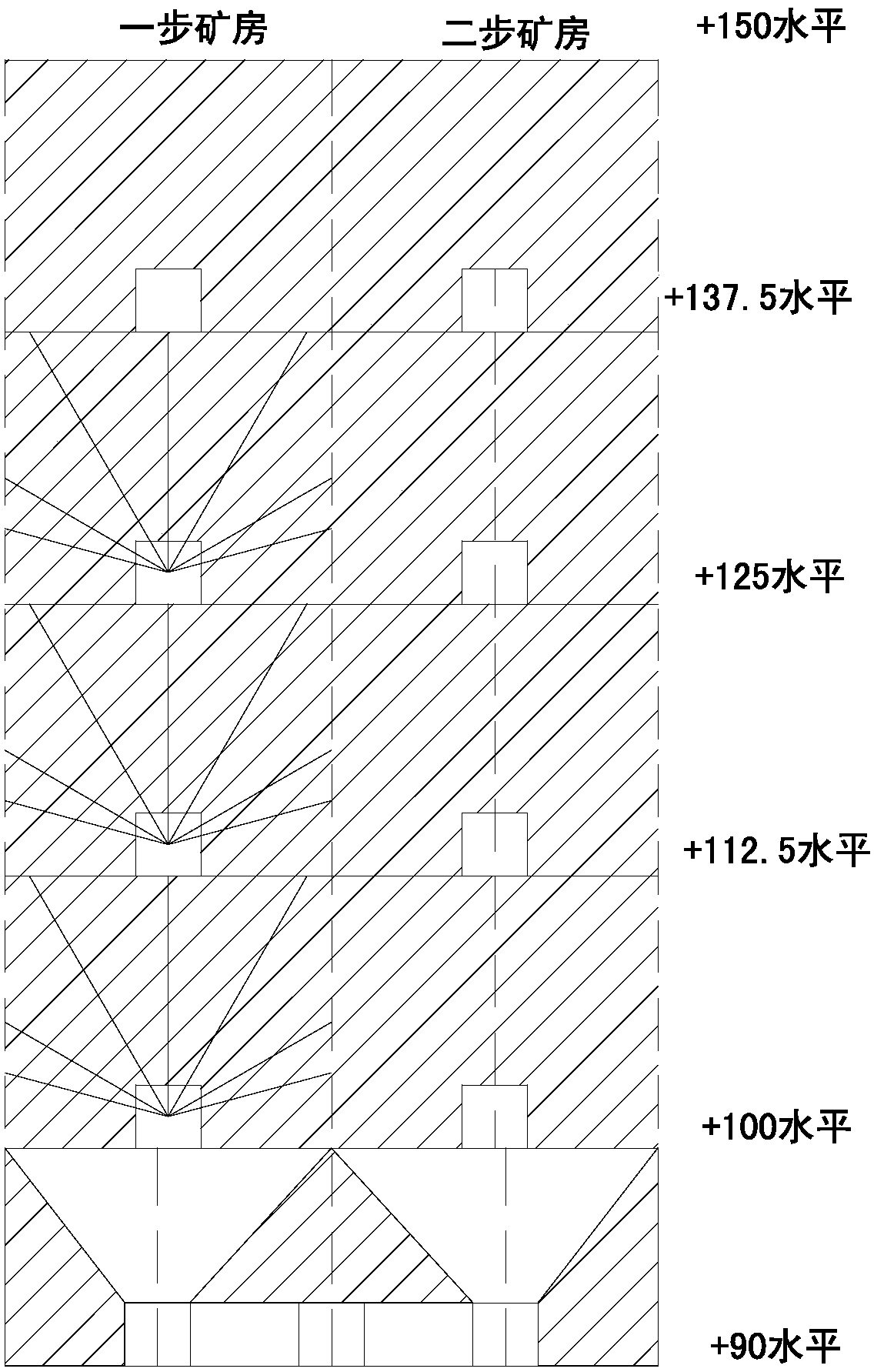

[0020] 1. Block layout (such as figure 1 , 2 shown) and structure parameters:

[0021] The ore blocks are arranged vertically, the width of the ore block is 30m, and the length is the thickness of the ore body. A total of 17 ore blocks are designed in this area. Each ore block is divided into two mining...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com