Shield starting tunnel portal extension steel ring

A steel ring and tunnel door technology, which is applied in mining equipment, earth-moving mining, tunnels, etc., can solve problems such as affecting the assembly of shield machines, inability to discharge dust smoothly, and deteriorating air quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

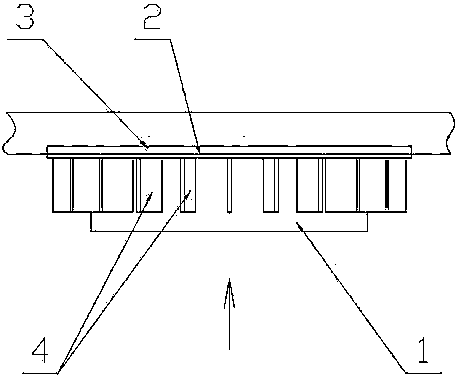

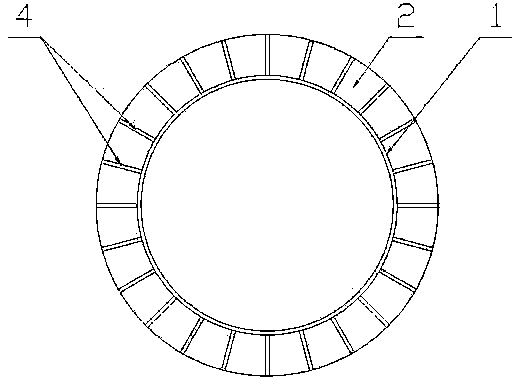

[0011] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as figure 1 , figure 2 Shown: an extended steel ring for the starting portal of a shield machine, which includes a steel ring body 1, the width of which is at least 45mm, and one end of the steel ring body 1 is connected with a first ring plate 2, the first ring The inner diameter of the plate 2 is the same as that of the steel ring body 1, the outer diameter of the first ring plate 2 is larger than the diameter of the steel ring body 1, forming a stepped ring plate, and the second ring plate 3 is fixedly connected with the first ring plate 2, The thickness of the second ring plate 3 is twice the thickness of the first ring plate 2, and the second ring plate 3 is pre-buried in the door wall. In order to enhance the overall strength, a plurality of ribs 4 are evenly distributed on the steel ring body 1 , and the difference between adjac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com