Foamed asphalt warm-mixing mixture and preparation method thereof

A technology of foamed asphalt and mixture, applied in the field of asphalt mixture, which can solve the problems of high cost, easy dispersion of dust, dust and sand, environmental pollution, etc., and achieve the effects of protecting the environment, improving the construction operation environment, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

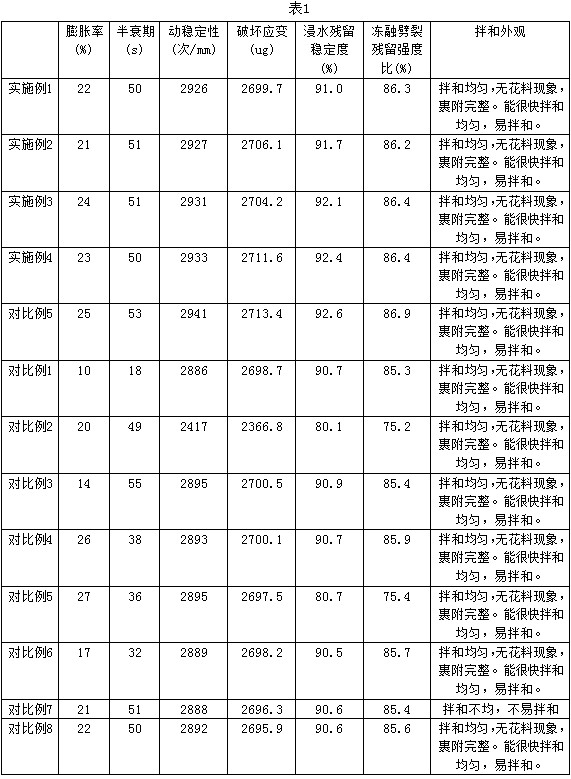

Examples

Embodiment 1

[0058] A preparation method for foamed asphalt warm mixture, comprising the following steps:

[0059] a. Heat 10kg of Buton Rock asphalt to 140°C, add 0.08kg of water containing 0.1kg of ethylene-vinyl acetate copolymer and 0.5kg of polyester fiber, and control the temperature of the water at 50°C to obtain foamed asphalt;

[0060] b. Heat 100kg of waste cement concrete recycled aggregate and 800kg of old asphalt pavement materials to 95°C and keep them warm for 5 hours, then mix them, and mix them at 95°C for 90s; then add the foamed asphalt prepared in step a at 140°C, and mix them at 140°C for 40s; Finally, add 20kg of ore powder preheated to 95°C and stir at 95°C for 90s to obtain the asphalt mixture.

[0061] Among the waste cement concrete regenerated aggregates and old asphalt pavement materials, aggregates with a nominal particle size of 0-2.36 mm, 0.36-4.75 mm, 4.75-9.5 mm, 9.5-16 mm, 16-19 mm, and 19-26.5 mm The weight ratio of materials is 18:24:14:16:4:5.

Embodiment 2

[0063] A preparation method for foamed asphalt warm mixture, comprising the following steps:

[0064] a. Heat 60kg of Buton rock asphalt to 160°C, add 0.9kg of water containing 0.5kg of styrene-butadiene latex and 0.1kg of glass fiber, and control the temperature of the water at 30°C to obtain foamed asphalt;

[0065] b. Heat 400kg of waste cement concrete recycled aggregate and 200kg of old asphalt pavement materials to 130°C and keep them warm for 3 hours, then mix them, and mix them at 130°C for 40s; then add the foamed asphalt prepared in step a at 130°C, and mix them at 130°C for 90s; Finally, add 200kg of ore powder preheated to 130°C, and stir at 130°C for 40 seconds to obtain the asphalt mixture.

[0066] Among the waste cement concrete regenerated aggregates and old asphalt pavement materials, aggregates with a nominal particle size of 0-2.36 mm, 0.36-4.75 mm, 4.75-9.5 mm, 9.5-16 mm, 16-19 mm, and 19-26.5 mm The weight ratio of materials is 25:17:19:10:10:1.

Embodiment 3

[0068] A preparation method for foamed asphalt warm mixture, comprising the following steps:

[0069] a. Heat 20kg of Butonite asphalt to 145°C, add 0.18kg of water containing 0.2kg of cocoyl glycinate potassium and 0.4kg of wood fiber, and control the temperature of the water at 35°C to obtain foamed asphalt;

[0070] b. Heat 150kg of waste cement concrete regenerated aggregate and 700kg of old asphalt pavement materials to 100°C and keep them warm for 3.5 hours, then mix them, and mix them at 100°C for 80s; then add the foamed asphalt prepared in step a at 132°C, and mix them at 132°C for 65s ; Finally, add 150kg of ore powder preheated to 100°C, and stir at 100°C for 80s to obtain the asphalt mixture.

[0071] Among the waste cement concrete regenerated aggregates and old asphalt pavement materials, aggregates with a nominal particle size of 0-2.36 mm, 0.36-4.75 mm, 4.75-9.5 mm, 9.5-16 mm, 16-19 mm, and 19-26.5 mm The weight ratio of materials is 20:22:16:14:6:4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com