Modular construction method for high temperature gas cooled reactor nuclear power plant containment bracket section wall

A nuclear power plant containment and high-temperature gas-cooled reactor technology, which is applied to building structures, buildings, industrial buildings, etc., can solve problems such as increased construction period, large-scale hidden dangers and safety risks, and achieves reduced construction difficulty, shortened critical path construction period, The effect of improving the construction work environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

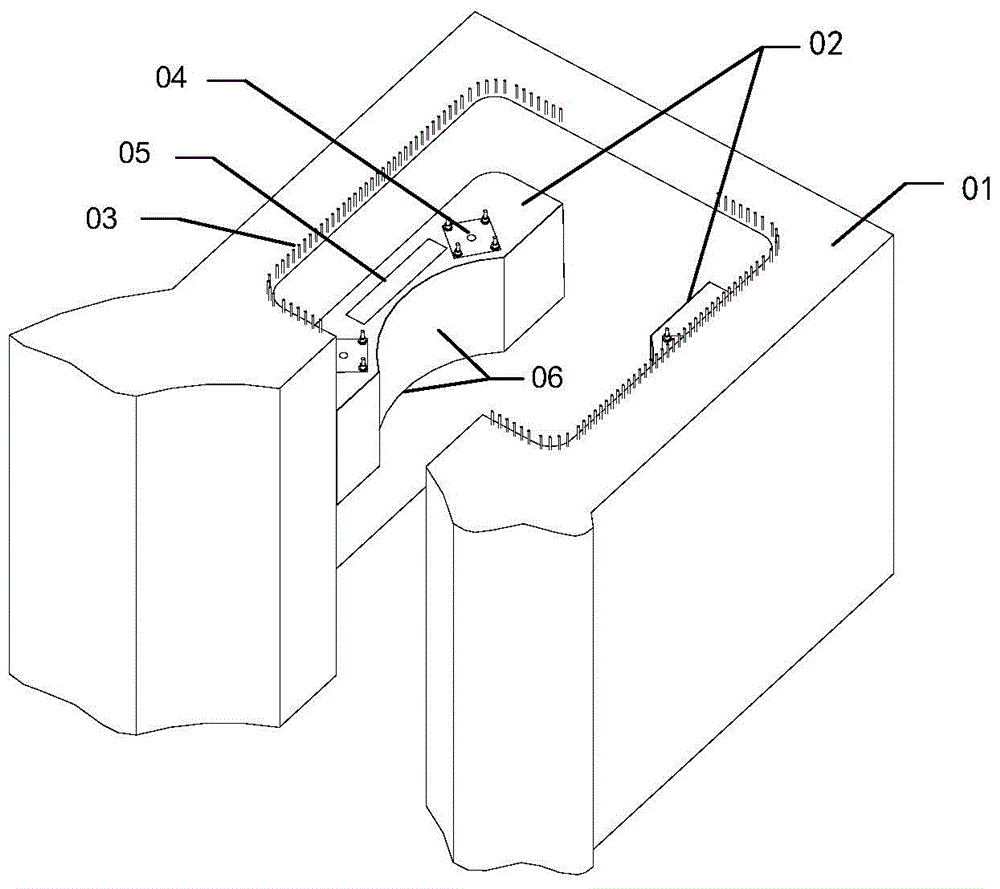

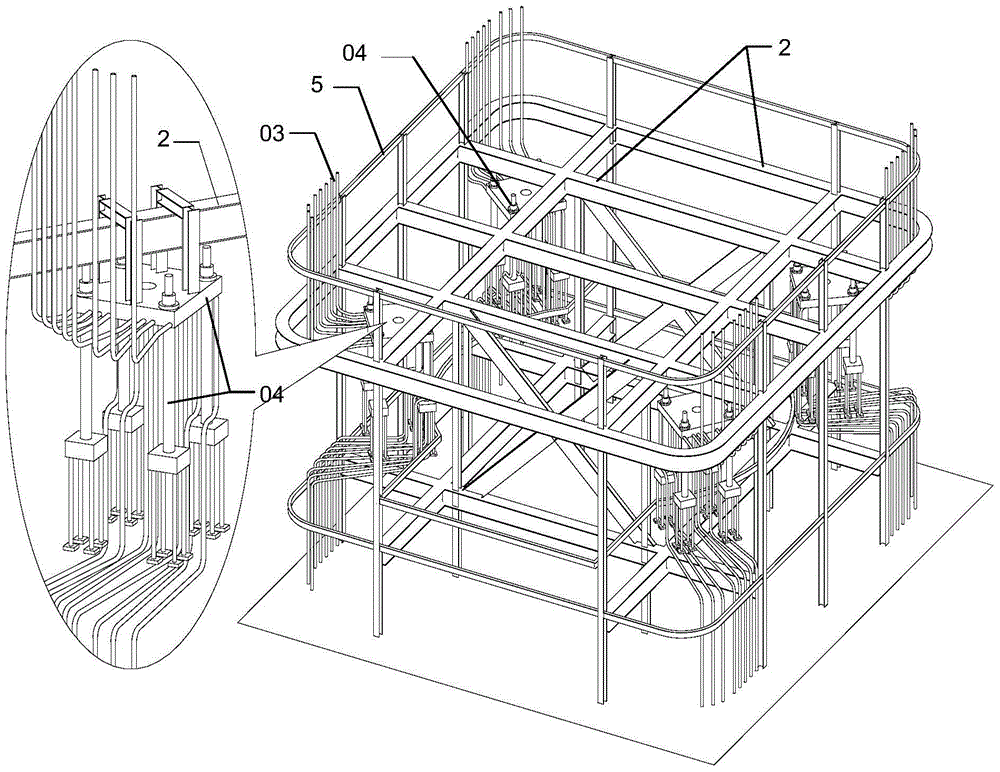

[0051] The modular construction method of the corbel section wall proposed by the present invention is characterized in that the method comprises two parts, the making of the corbel section wall module and the construction of the corbel section wall, and the specific implementation includes the following steps:

[0052] 1) Fabrication of corbel section wall modules

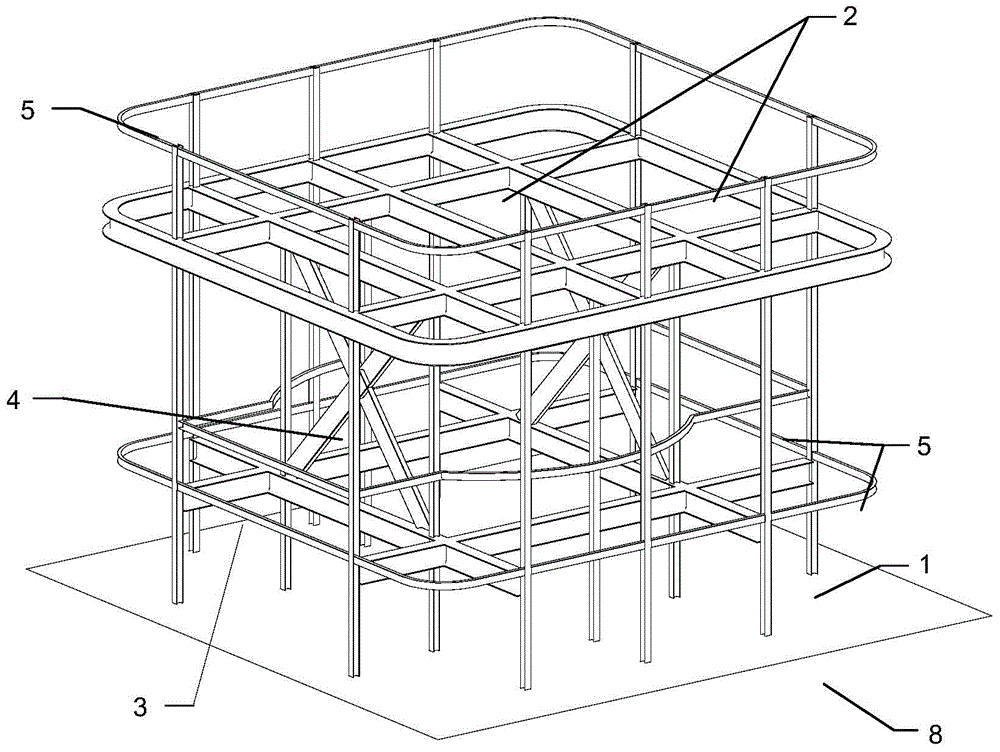

[0053] The fabrication of the corbel section wall modules is completed on the off-site module fabrication steel platform (see Figure 2 ~ Figure 6 )

[0054] (1-1) Build a module to make a steel platform:

[0055] According to the overall layout of the construction and the performance of the selected crane, select a module production site that can meet the simultaneous or continuous construction of multiple modules outside the wall of the corbel section, and build a module production steel platform 8 in the area of the module production site. Off-site prefabrication and assembly of wall modules in the corbel s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com