Tunnel construction cooling device and method

A tunnel construction and cooling device technology, which is applied in mine/tunnel ventilation, heating methods, earthwork drilling and mining, etc., can solve problems affecting civilized construction, high pumping costs, muddy upper guide pits, etc., to improve the construction operation environment, Reduce labor costs and ensure the effect of construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

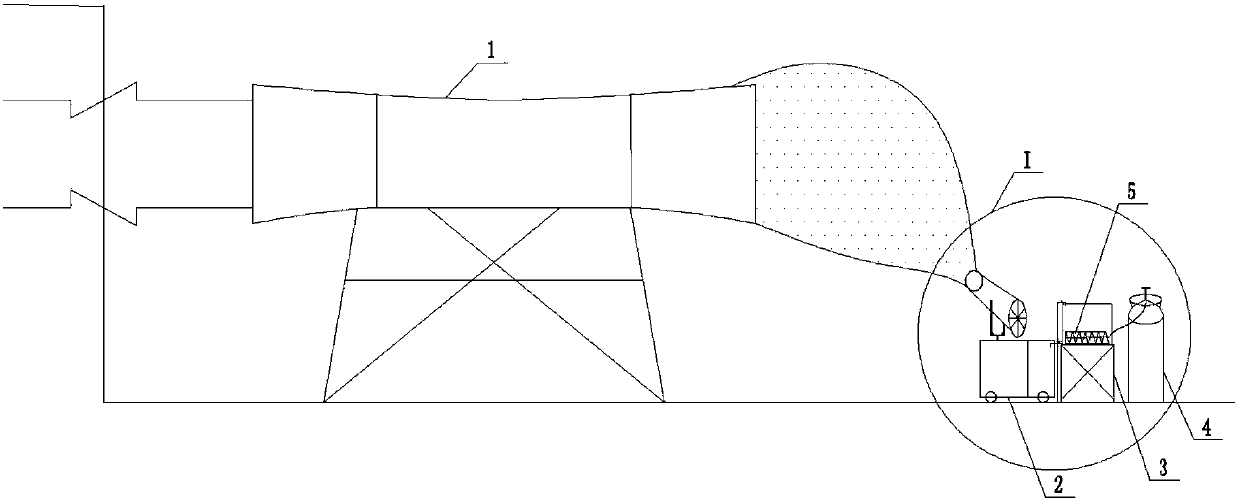

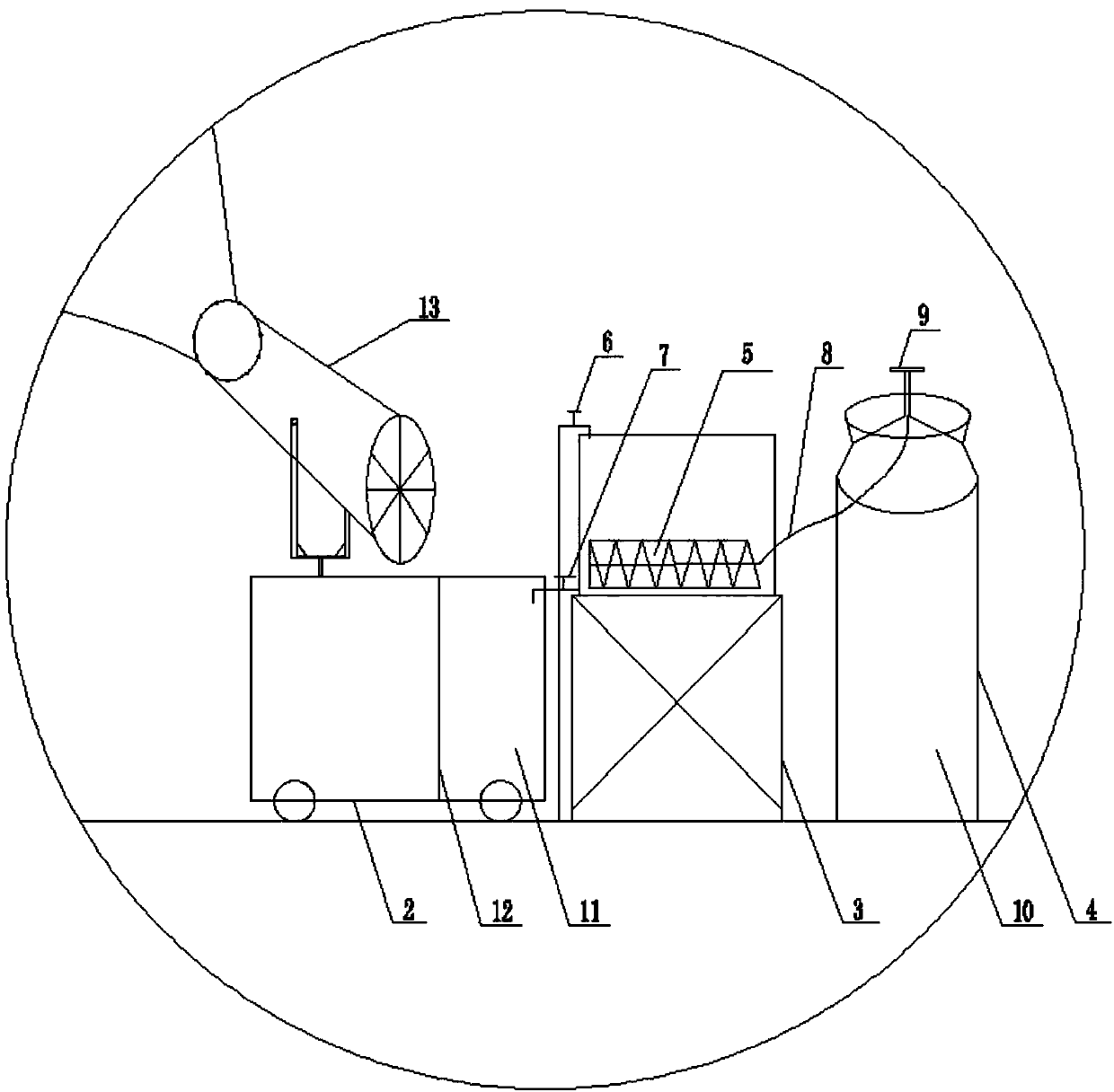

[0034] Such as figure 1 , 2 As shown, a cooling device for tunnel construction includes a press-in fan 1, a fog cannon machine 2, a thermal insulation water tank 3 and a cooling device. The input end is connected, and the output end of the fog cannon machine 2 is set opposite to the input end of the press-in fan 1 . A running water ball valve 6 is installed on the top of the heat preservation water tank 3, a water pipe ball valve 7 is installed on one side of the middle part of the heat preservation water tank 3, the cooling device is a cooling pipeline 5, and one end of the cooling pipeline 5 is provided with a plurality of drain holes, and the heat preservation water tank 3 is provided with The liquid nitrogen supply device 4, the thermal insulation water t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com