Removal-free prefabricated reinforced concrete template with cross holes inside and manufacturing method thereof

A reinforced concrete prefabricated panel and reinforced concrete technology, which is applied to the preparation of formwork/formwork/work frame, formwork/formwork components, and building components on site, can solve problems such as complicated procedures, and reduce workload and reduce The workload and difficulty of construction, and the effect of facilitating long-distance transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

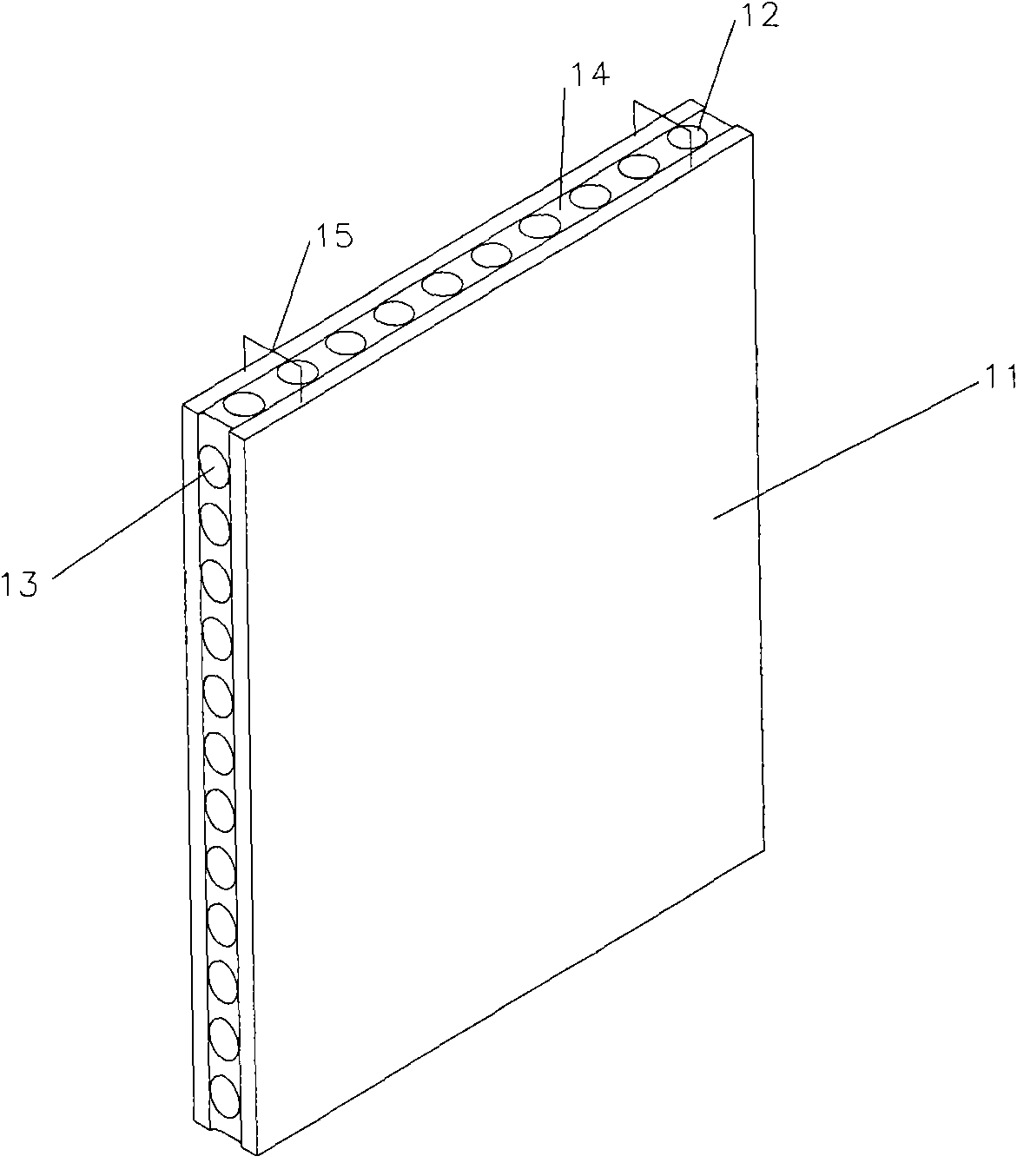

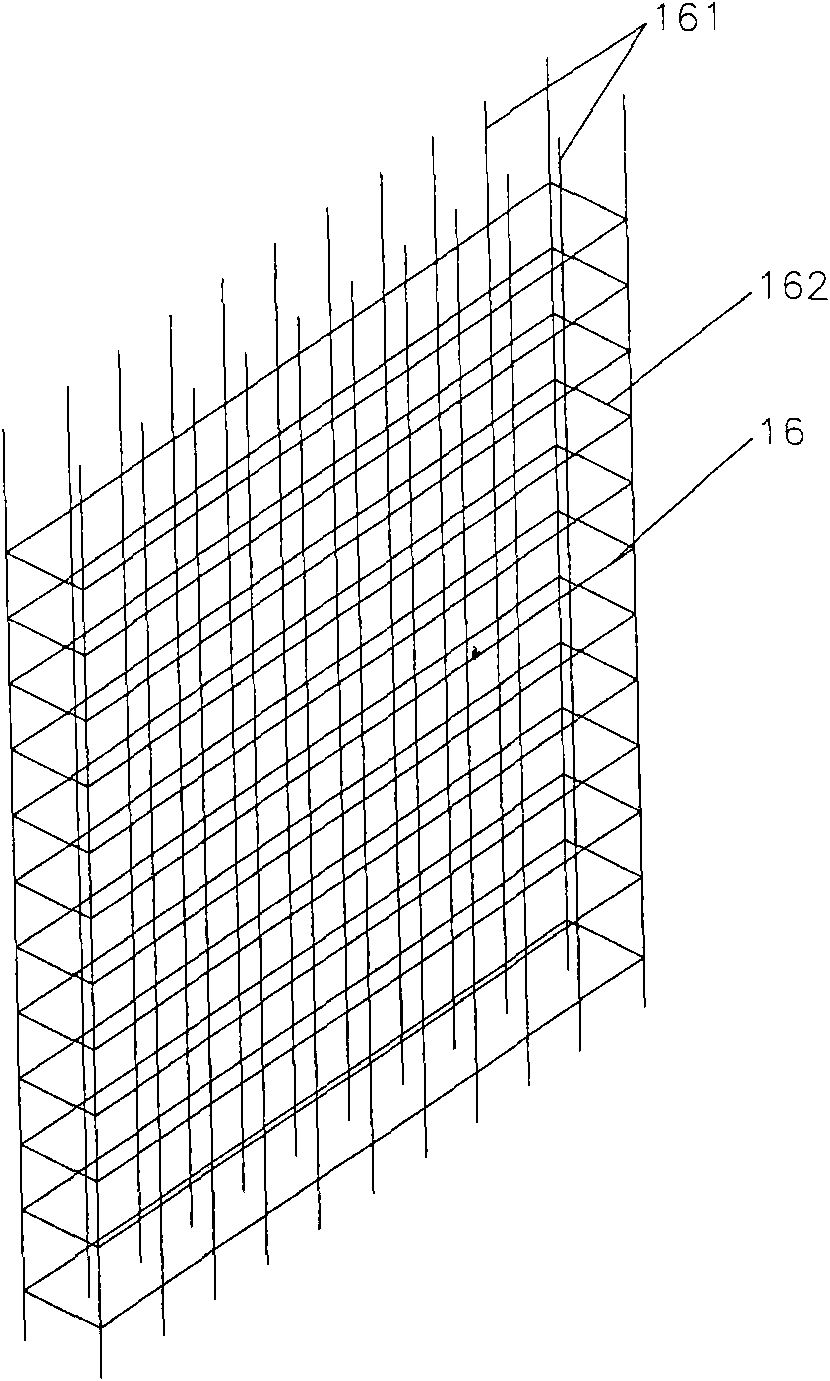

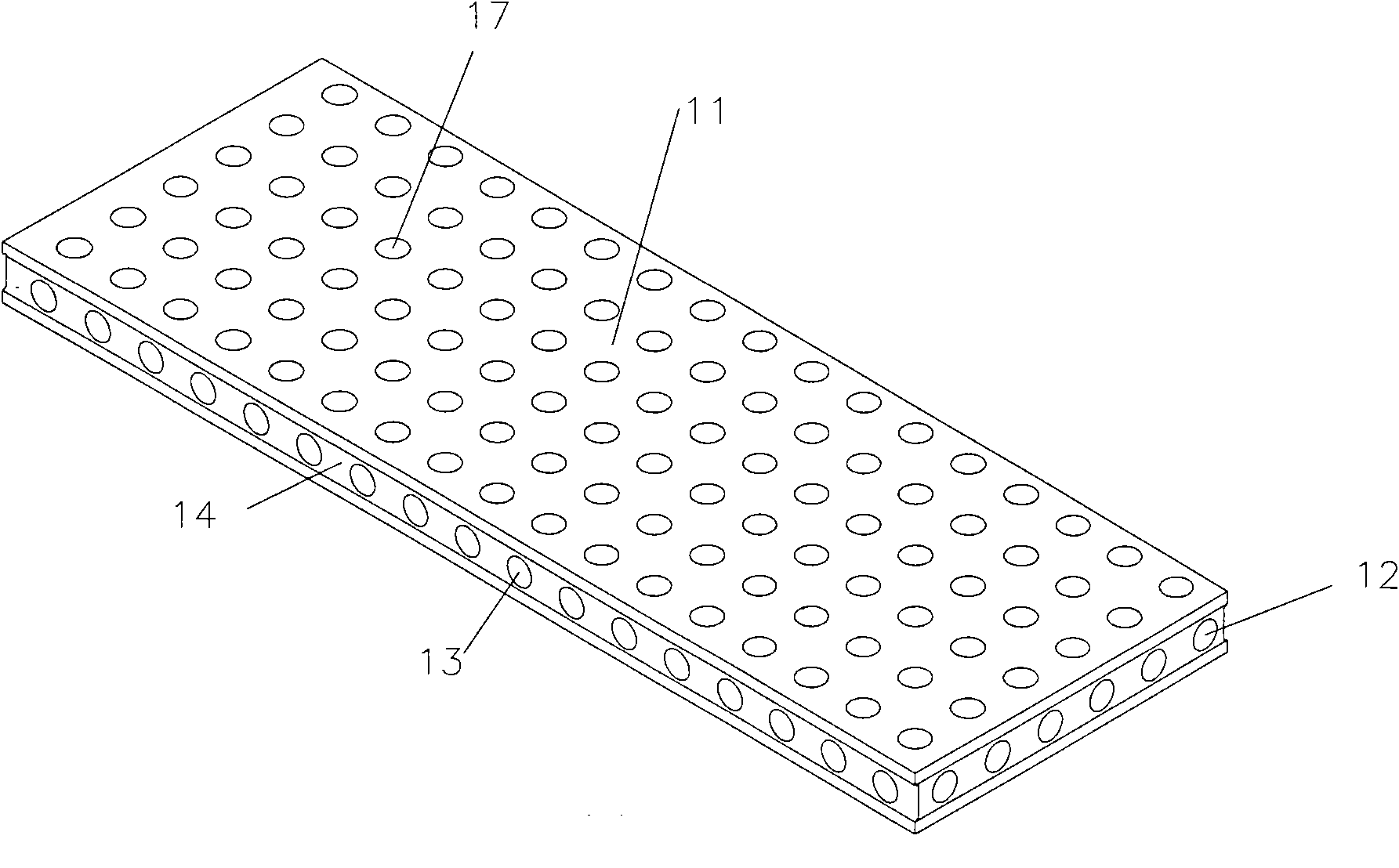

[0041] Embodiment 1 is a flat-type demolition-free prefabricated reinforced concrete formwork with intersecting holes inside. The formwork adopts a prefabricated reinforced concrete slab, such as Figure 1a As shown, there is a row of longitudinal through holes 12 and a row of transverse through holes 13 in the plane of the reinforced concrete prefabricated slab 11; Arranged longitudinal steel bars 161 and a plurality of transverse stirrups 162 that connect the steel bars into a whole, such as Figure 1b As shown; it also includes a groove 14 arranged on the side of the reinforced concrete prefabricated slab 11, and an installation ring 15 on one side of the reinforced concrete prefabricated slab; the diameter range of the longitudinal through hole is between 60mm and 300mm ( In general, take the plate thickness minus 60mm. For example, when the plate thickness is 200mm, the diameter of the longitudinal through hole is 140mm). The diameter of the transverse through hole ranges...

Embodiment 2

[0051] Embodiment 2 is a prefabricated reinforced concrete formwork with intersecting holes inside a T-shaped column that does not need to be dismantled. The formwork adopts a T-shaped reinforced concrete prefabricated panel 31, such as Figure 3a As shown, there are vertical through holes 32 in the formwork, and through holes 33 are formed horizontally in the formwork. Grooves 34 are provided on five sides (left, right, front, upper surface, and lower surface) of the T-shaped column formwork. The upper surface is provided with a formwork suspension ring 35 for construction and installation, and a reinforcement cage 36 is arranged in the column formwork, and the reinforcement cage 36 is composed of a plurality of longitudinal reinforcement bars 361 and a plurality of transverse stirrups 362 (T-shaped stirrups), such as Figure 3b shown. The vertical height of the T-shaped column formwork is about 2400mm to 5000mm (generally the height of the building), and the thickness of eac...

Embodiment 3

[0060] Embodiment 3 is a demolition-free prefabricated reinforced concrete coupling beam formwork 71 with intersecting holes inside, the formwork adopts reinforced concrete prefabricated coupling beams, and vertical through holes 72 and horizontal through holes 73 are opened in the coupling beam formwork 71 ,like Figure 7c Shown; The groove 74 that is arranged on three sides of coupling beam formwork, as Figure 7a Shown; The reinforcement cage 76 that is arranged in the connecting beam formwork, this reinforcement cage 76 is made up of a plurality of longitudinal reinforcements 761 and a plurality of transverse stirrups 762 that the longitudinal reinforcement 761 is fixedly connected into a whole, as Figure 7b shown. One end of the stirrup 762 is exposed and can be used as an installation ring. The length of the coupling beam formwork is generally about the size of the door and window opening plus 600mm, the height of the coupling beam formwork is the size from the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com