Ribbon-shaped single-tower cable-strayed-steel structure combined bridge and construction process thereof

A technology for combining bridges and streamers, which is applied in the direction of cable-stayed bridges, bridges, bridge materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

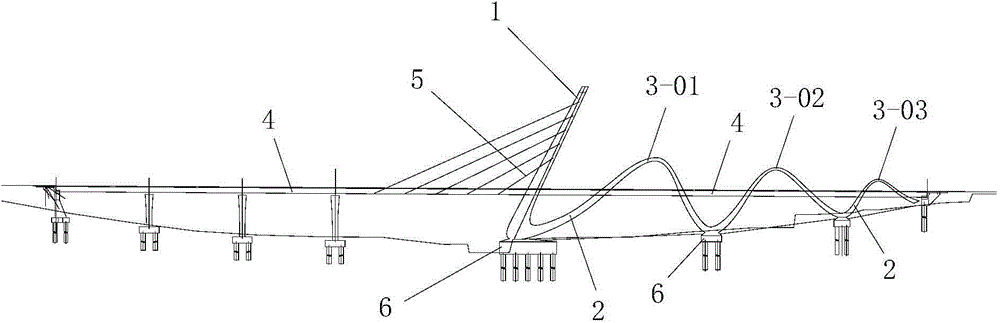

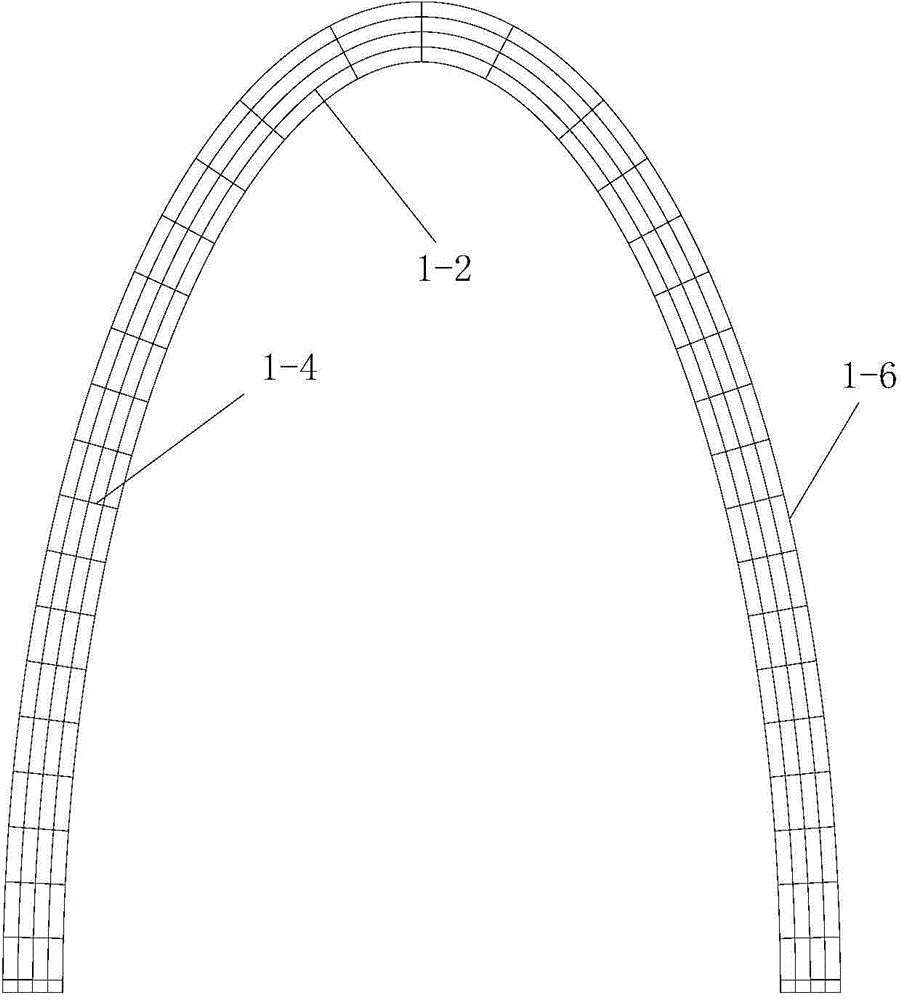

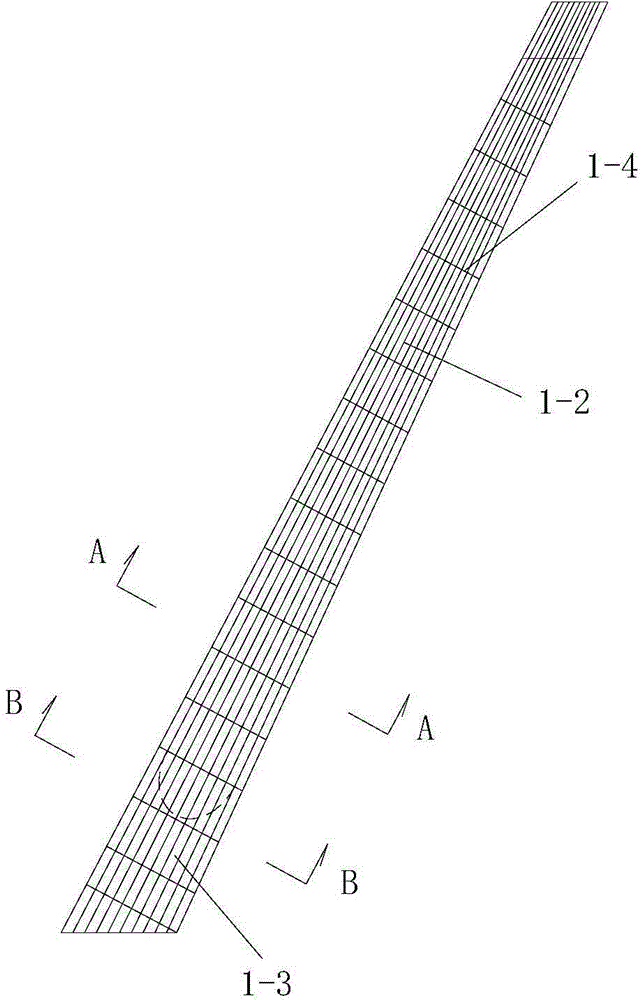

[0085] Such as figure 1 A ribbon-shaped single-tower cable-stayed-rigid frame composite bridge is shown, including the lower support structure of the bridge, the main girder 4 located above the lower support structure of the bridge, which is arranged on the main girder 4 and gradually tilts backward from bottom to top The main tower 1 and two ribbon-shaped support structures located on the rear side of the main tower 1, the main tower 1 is arched, and the structures of the two ribbon-shaped support structures are the same and they are arranged symmetrically on the left and right sides of the main tower 1 On both sides, the two streamer-shaped support structures are fastened together with the main girder 4 and both are arranged along the longitudinal direction of the bridge. Between the main tower 1 and the main girder 4, a plurality of stay cables 5 are arranged, and the stay cables 5 are arranged from top to bottom and are all located at the front side of the main tower 1. Ea...

Embodiment 2

[0138] In this example, if Figure 9 As shown, the number of the single-tower cable-stayed ribbon-shaped combined force-bearing system is two, and the two single-tower cable-stayed ribbon-shaped combined force-bearing systems are arranged symmetrically.

[0139] During actual construction, according to specific needs, the number of the single-tower cable-stayed ribbon-shaped combined stress system is adjusted, and by increasing the single-tower cable-stayed ribbon-shaped combined stress system, the ribbon-shaped independent stress system of the construction is increased. Spanning capacity of tower cable-stayed-rigid frame composite bridge.

[0140] In this embodiment, the structures, connections and construction techniques of the remaining parts are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com