Foundation treatment method of collapsible loess slope cut-and-fill joint part

A technology for collapsible loess and foundation treatment, which is applied in excavation, filling, soil protection, etc., and can solve the problems of uneven settlement and poor bonding effect at the junction of filling and excavation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

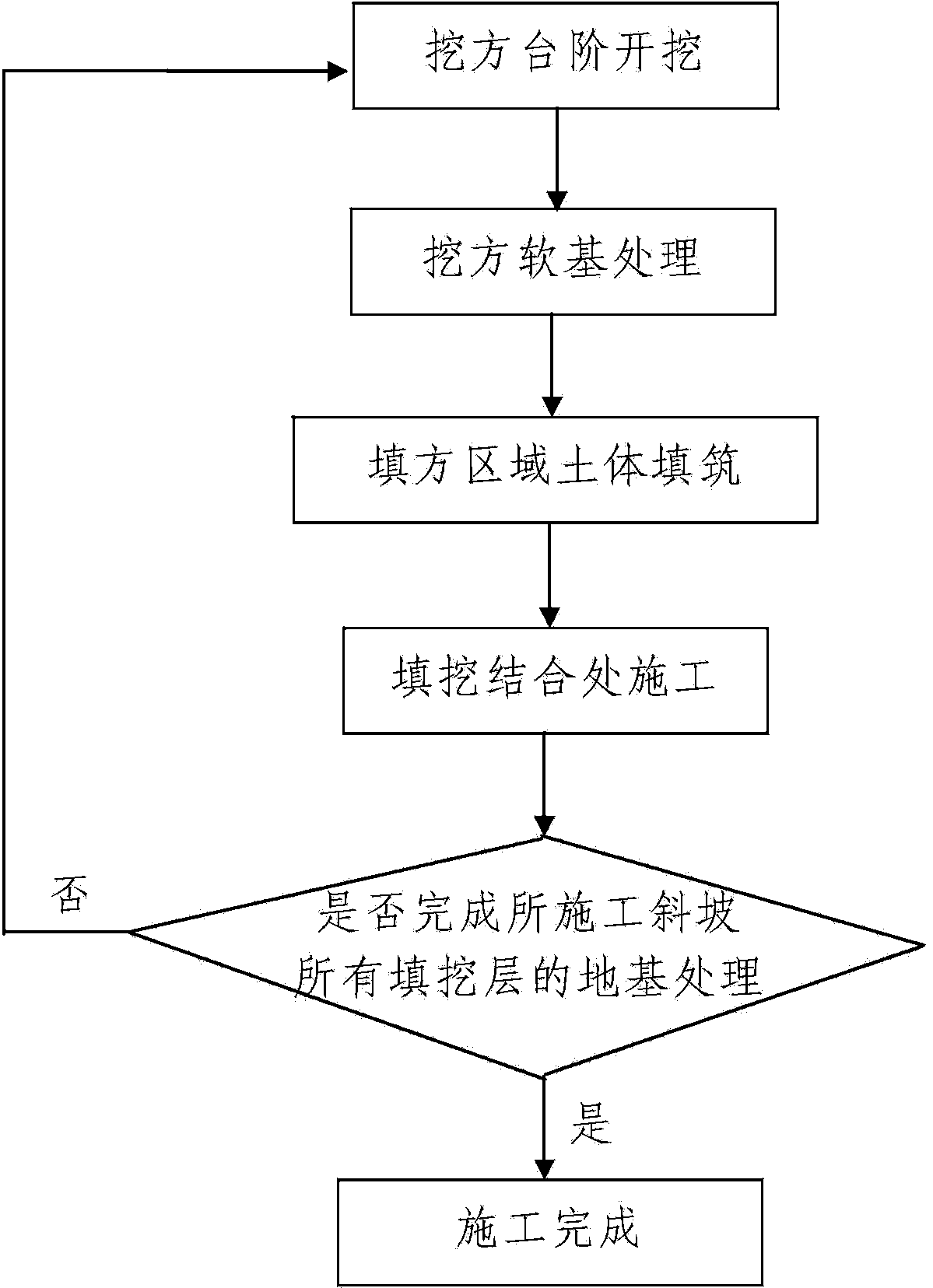

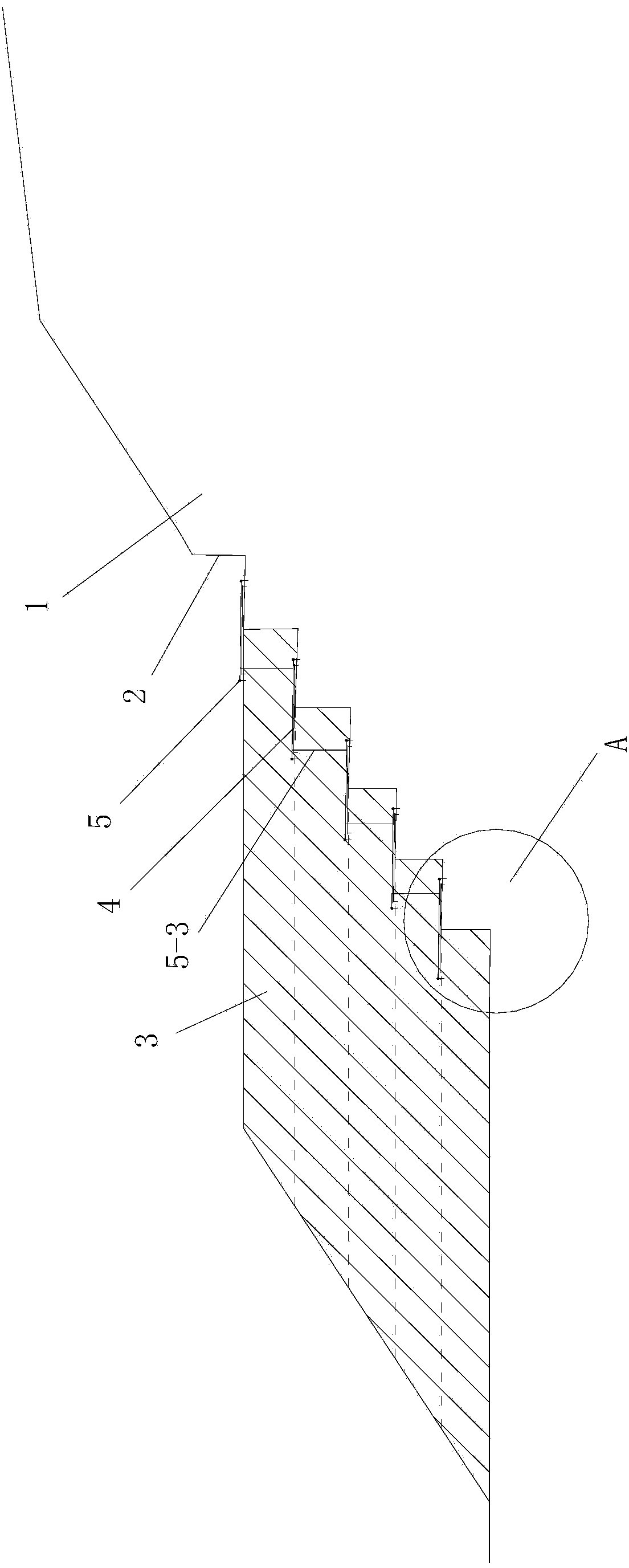

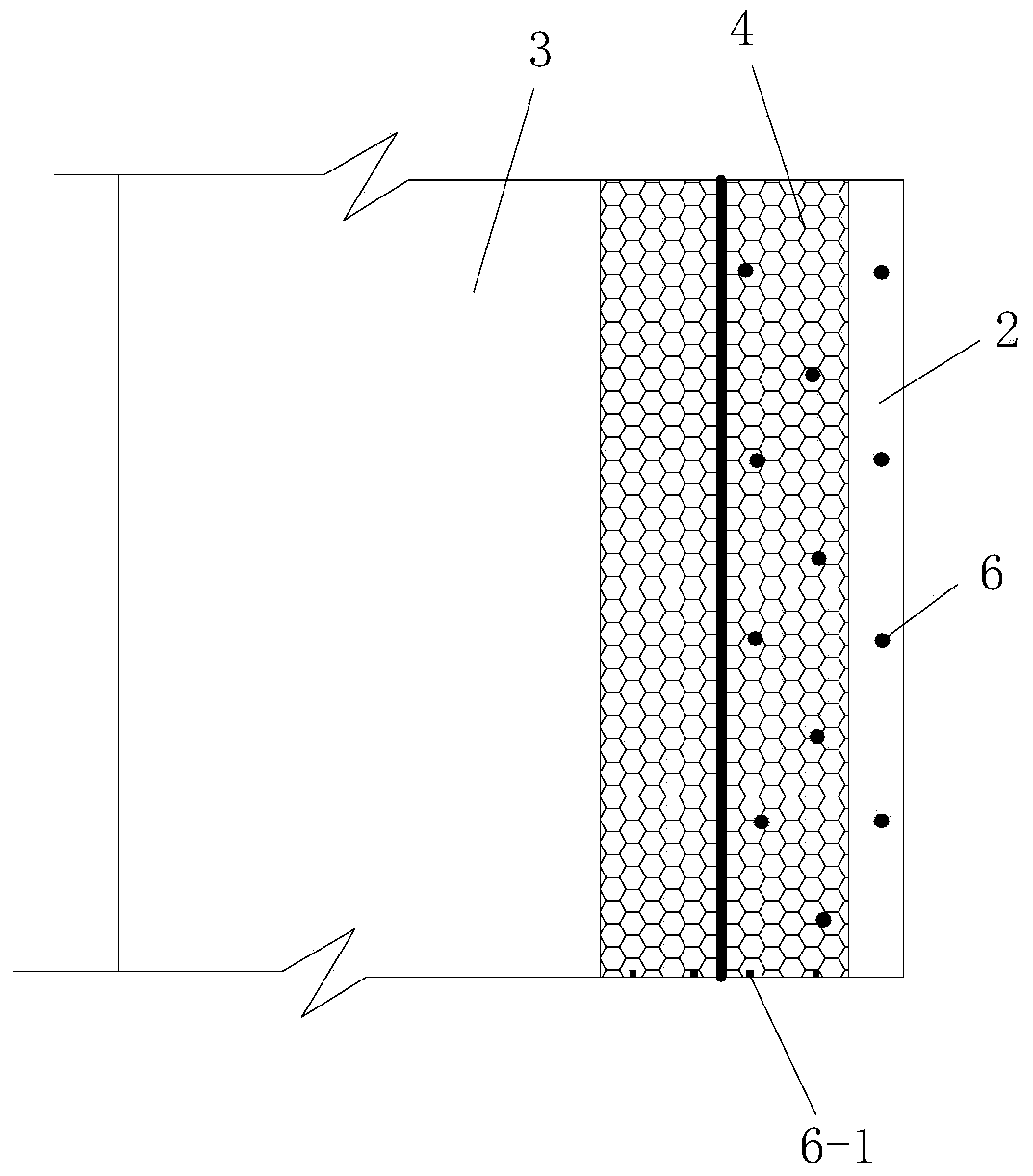

[0073] like figure 1 A method for foundation treatment of the excavation and filling junction of a collapsible loess slope is shown. From top to bottom, M filling and excavation layers are used to perform foundation treatment on the excavation and filling junction of the constructed slope 1, and the M excavation and filling layers The foundation treatment methods of the layers are all the same; wherein, M is a positive integer and M≥3; the layer thickness of the M filling and excavation layers is not more than 1m; the filling and excavation layer at the bottom of the M filling and excavation layers is Dig the bottom layer; the slope 1 constructed is a collapsible loess slope, and the slope 1 constructed is excavated to form a step comprising M steps 2, the M steps 2 are arranged from bottom to top, and the M steps 2 The height of the kick surface is the same as the layer thickness of the M filling and excavation layers respectively, and the arrangement positions of the M steps...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com