A construction structure and construction method for building an empty box structure of a ship lock

A technology for empty boxes and ship locks, which is applied in ship locks, building structures, and processing of building materials, etc., can solve the problems of poor connection effect and inability to form concrete, save construction time and engineering materials, reduce costs, and improve construction efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

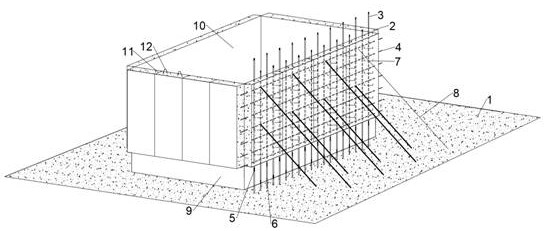

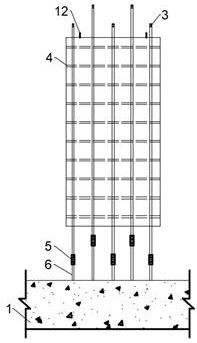

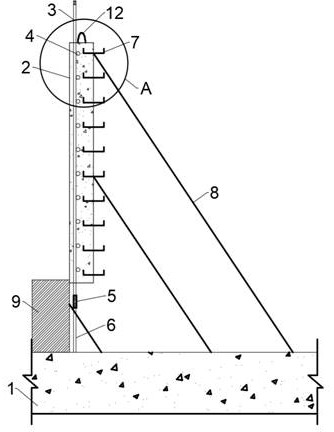

[0039] combine figure 1 As shown, a construction structure for building an empty box structure 10 of a ship lock is disclosed in this embodiment, including a pouring main body 1 and an empty box structure 10, the empty box structure 10 is located on the pouring main body 1, and the empty box structure 10 It includes a back cover formwork 9 and a plurality of side wall formworks 2. The back cover formwork 9 is placed flat on the pouring main body 1. The plurality of side wall formworks 2 are vertically arranged on the four sides of the back cover formwork 9. Around the back cover formwork 9, there are The pre-embedded steel bars 6 buried in the pouring main body 1, each side wall form 2 includes a plurality of precast concrete formworks, the precast concrete formwork is fixedly connected with the pre-embedded steel bars 6, and the pre-embedded steel bars 6 are used for supporting and fixing A prefabricated concrete formwork, the side wall formwork 2 and the bottom cover formwor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com