A grinding device for supporting a welding roller frame

A technology of welding rollers and wheel frames, which is applied in the direction of grinding drive devices, grinding machines, abrasive belt grinders, etc., can solve the problems of low operating efficiency of grinding devices, achieve complex tensioning structures, improve construction quality, and reduce the center of gravity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

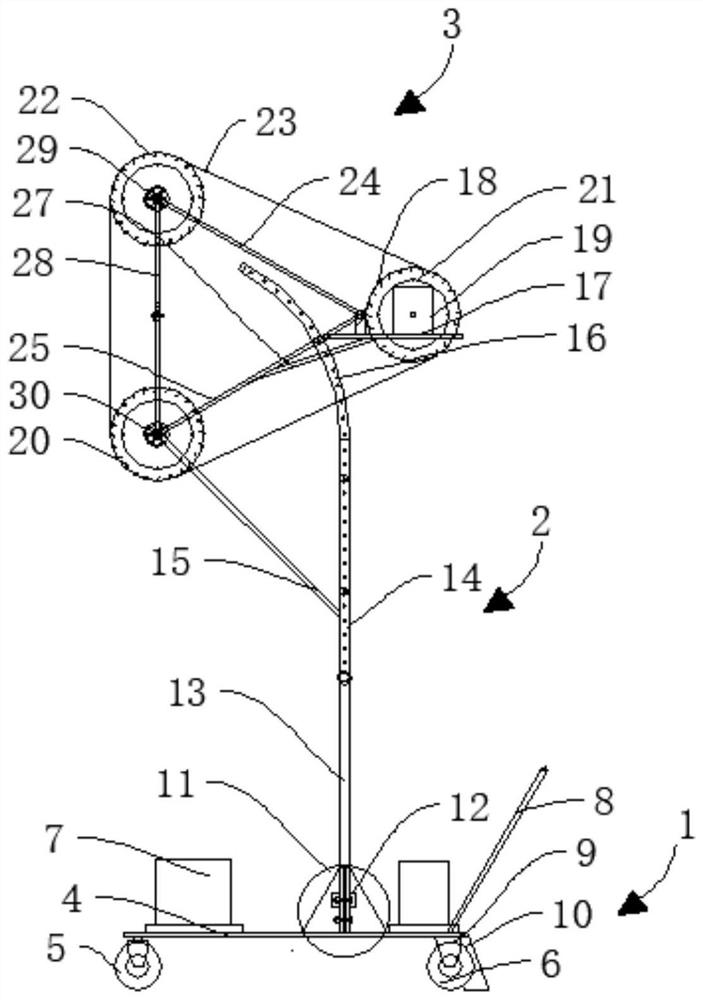

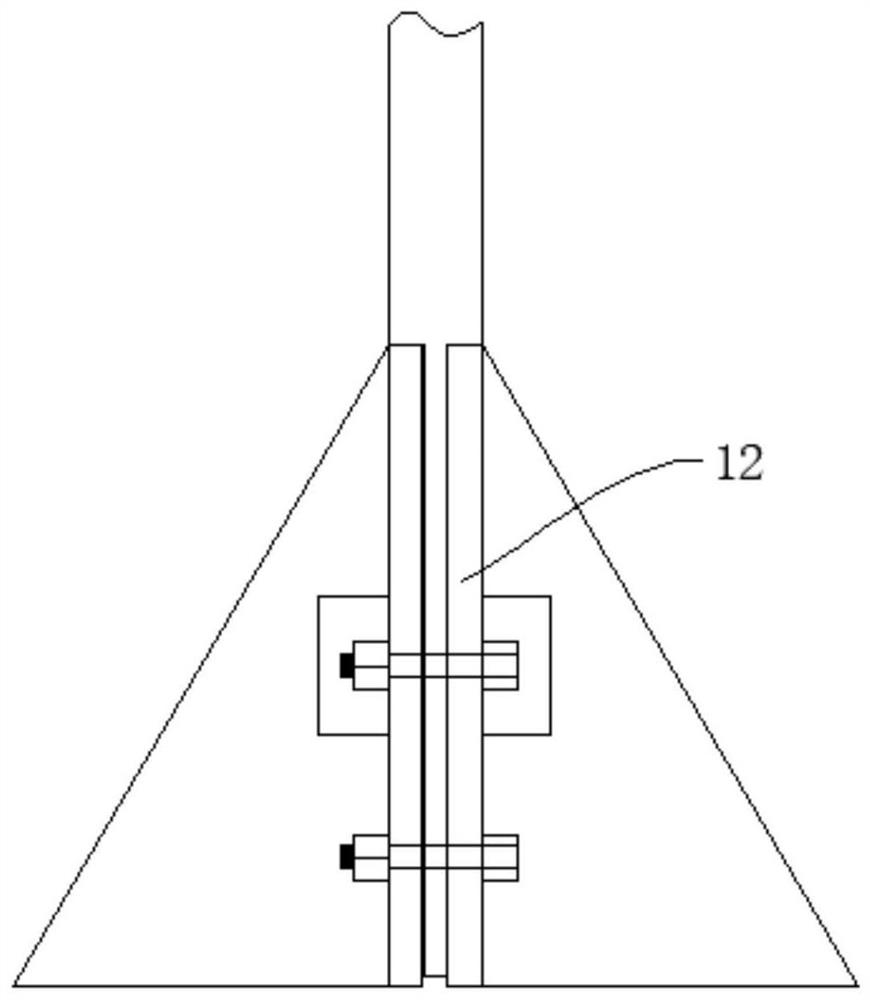

[0041] Please refer to figure 1 , Cooperate with reference Figure 2 to Figure 14 , This application provides a polishing device for welding roller wheel rack, which mainly includes three major parts: mobile support mechanism 1. adjustment mechanism 2 and polishing mechanism. Among them, the adjustment mechanism 2 height and angle can be adjusted to mobile support support Institutional 1 is used to regulate the height and polishing angle of the polishing mechanism 3; the disassembly of the polishing mechanism 3 is installed on the upper part of the regulatory mechanism 2.

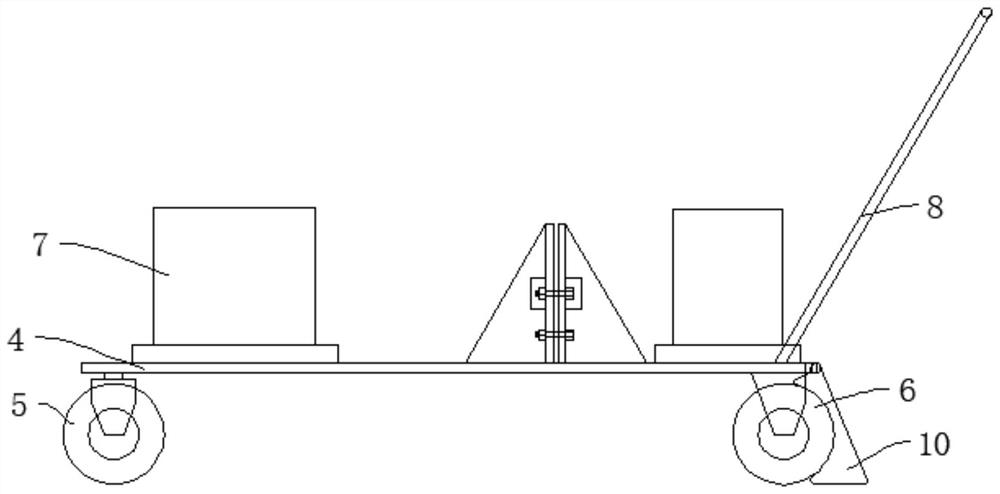

[0042] Further, the mobile support mechanism 1 is a flat -screen car structure, which mainly includes supporting seats 4. Multiple front wheels 5, multiple rear wheels 6, multiple weight blocks 7, handrails 8, multiple wedge -shaped blocks 9, multiple more and more multi -wedding pages, and multiple wedge -shaped blocks 9 and multi -multi -multi -multi -wedding blocks. A rubber wedge -shaped block 10; Among them...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com