Demolition construction method for large-span cable crane adjacent to railway business line

A construction method, technology of business lines, applied in the direction of cable cranes, clockwork mechanisms, load-hanging elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

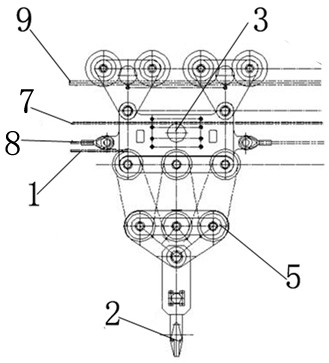

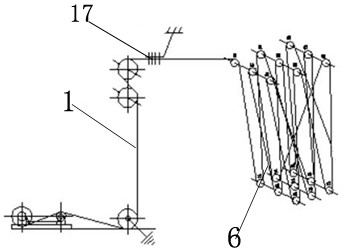

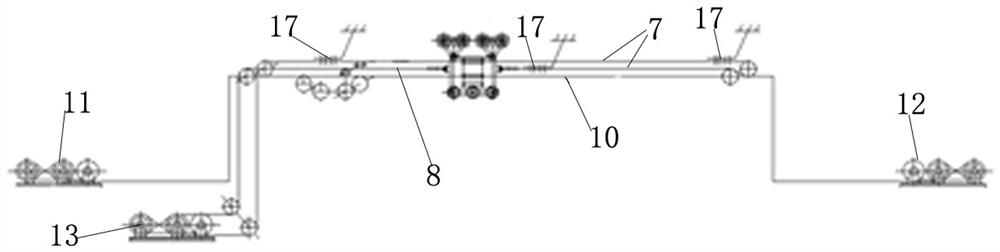

[0040] refer to Figure 1-23 , a construction method for dismantling a large-span cable hoist adjacent to a railway business line according to the present invention will be described in detail.

[0041] A large-span cable crane demolition construction method adjacent to the railway business line is characterized in that it comprises the following steps:

[0042] Step 1: First remove the hoisting rope 1. Before removing the hoisting rope 1, move the cable hook 2 and the crane 3 to the inspection platform on the top of the near-end tower 4, and first connect the hoisting rope 1 to the near-end tower. The frame 4 is connected with a steel wire rope to prevent slipping, and the pulley block 6 matched with the hoisting rope 1 is removed, and then the hoisting rope 1 is connected with the hoisting rope of the first hoist at the top of the near-end tower frame 4, and the first hoist is a 5T hoist , to disconnect the hoisting rope 1 and the near-end tower 4 is to untie the steel wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com