A construction method for small-section shafts without removing formwork

A construction method and form removal-free technology, applied in the direction of vertical pipelines, buildings, building components, etc., can solve the problems of low work efficiency, cumbersome removal of formwork, and large safety hazards, so as to reduce safety hazards, facilitate quality control, The effect of speeding up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

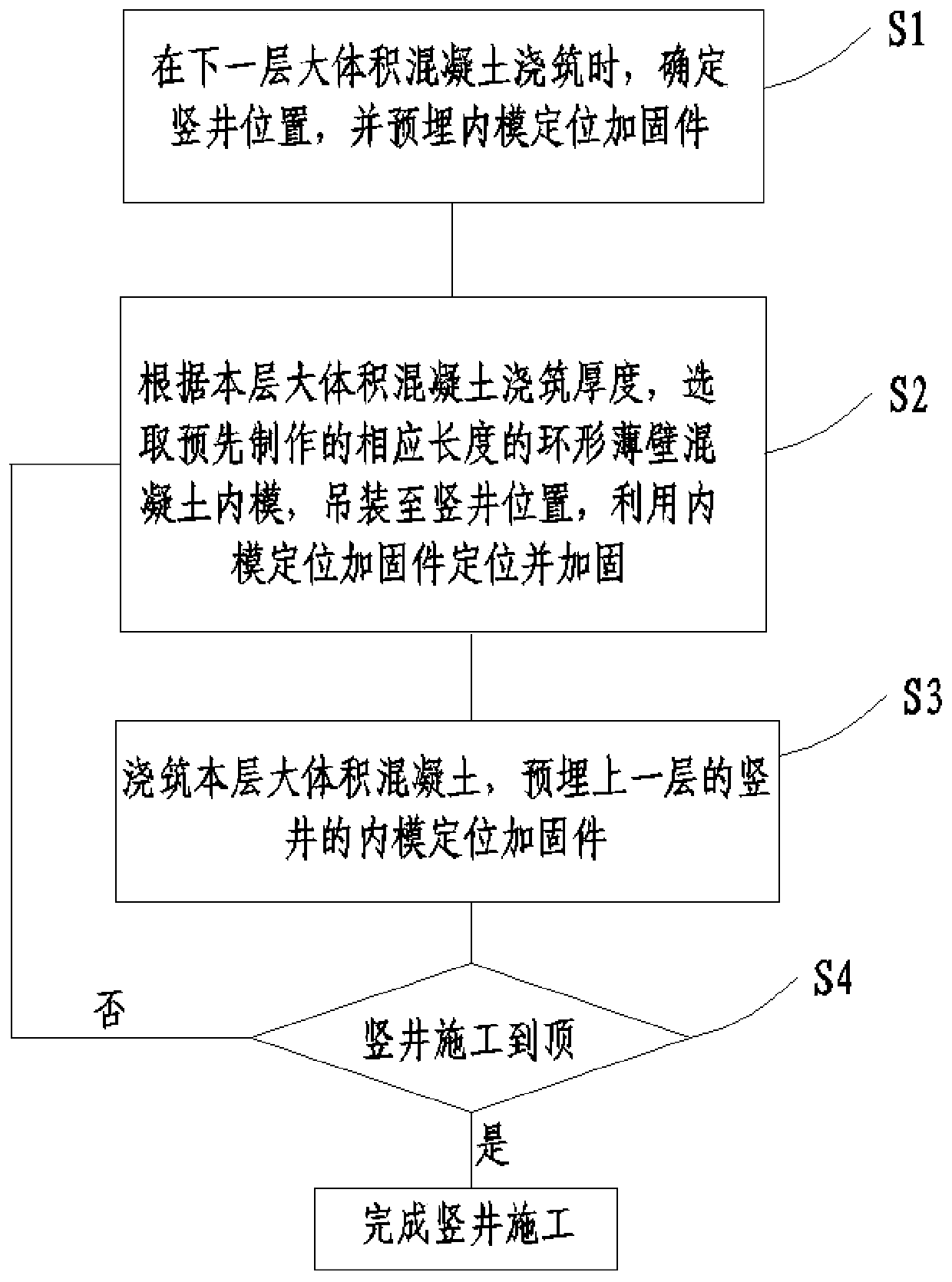

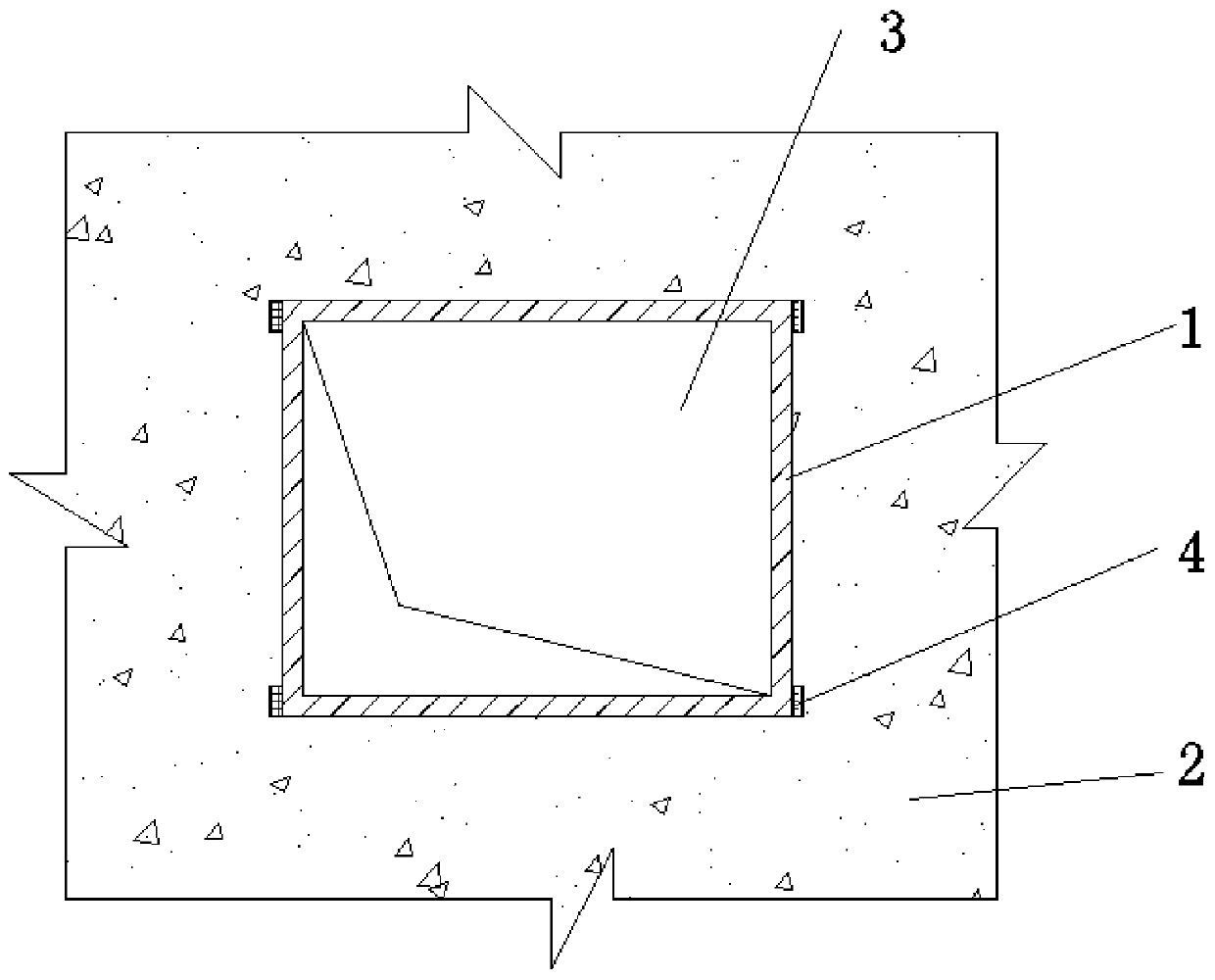

[0026] Such as figure 1 and figure 2 As shown, the construction method of the small-section vertical shaft without removing formwork of the present embodiment prefabricates a plurality of annular thin-walled concrete inner molds 1 with a certain length, and the construction method of the small-section vertical shaft without removing the formwork includes the following steps:

[0027] S1: When pouring the next layer of mass concrete 2, determine the position of the shaft 3, and pre-embed the internal formwork positioning reinforcement 4;

[0028] S2: According to the pouring thickness of the mass concrete 2 of this layer, select a prefabricated circular thin-walled concrete inner mold 1 of corresponding length, hoist it to the position of the shaft 3, and use the inner mold positioning reinforcement 4 to position and reinforce it;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com