Building truss integral lifting method and equipment thereof

A technology for overall lifting and building, applied in building structures, buildings, truss structures, etc., can solve the problems of poor safety, large materials for supporting and splicing tire frames, labor-intensive, etc. Saving and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

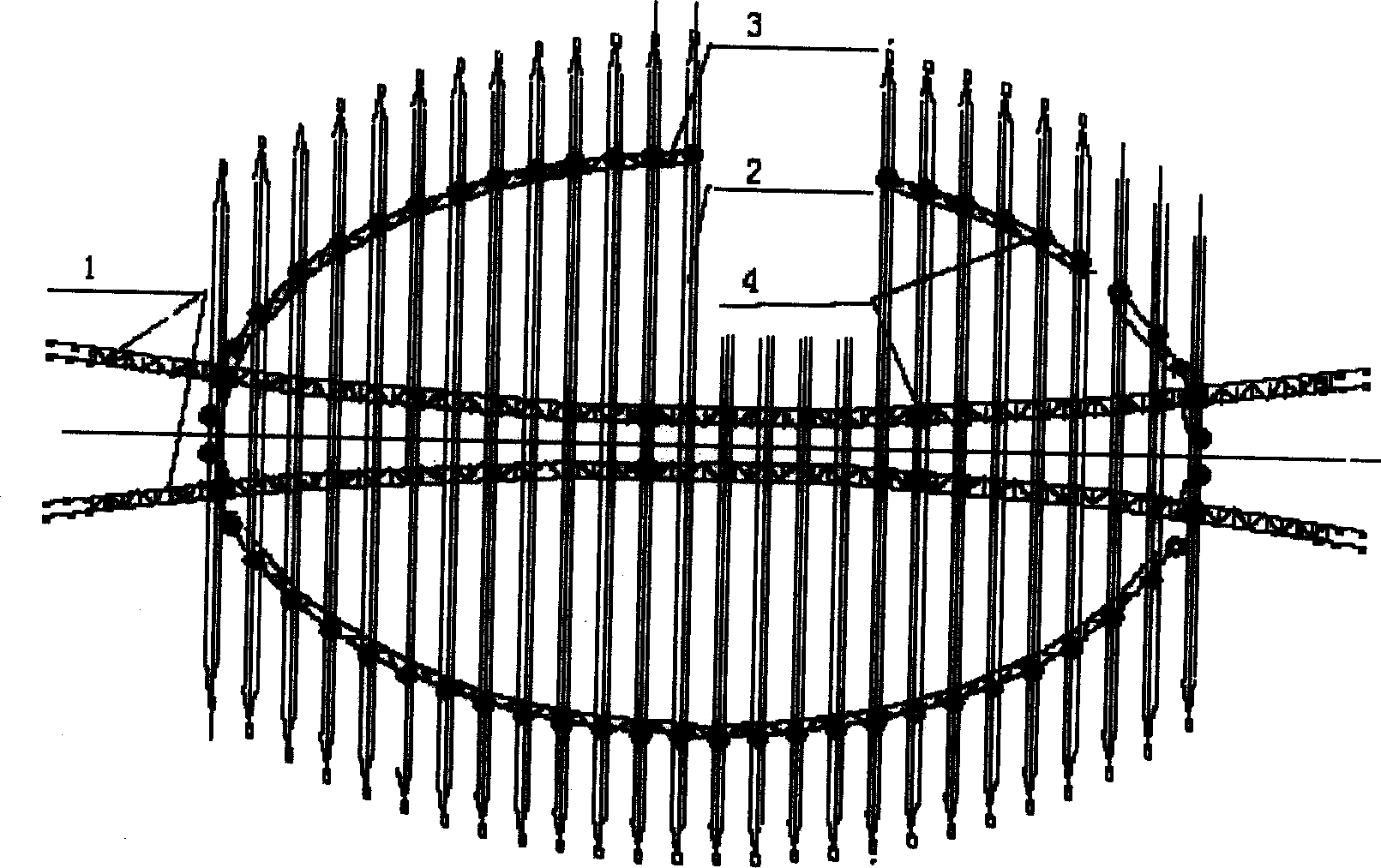

[0036] figure 1 A plan view of a steel roof system is shown in . The entire steel roof system has a total of 26 secondary trusses 2 placed in parallel, and circumferential ring trusses 3 are arranged around the secondary trusses 2, and there are longitudinally arranged main trusses 1 and 1 in the middle of all the arranged secondary trusses 2 , the secondary truss 2 and the hoop truss 3 are fixed to each other and supported by the supporting steel column 4 . The main steel structure of the roof covering the entire venue space is formed by the rigid connection of two long-span space main trusses with a span of 320 meters in the longitudinal direction, 26 latitudinal secondary trusses with a maximum span of 224 meters (average span 190 meters), and ring trusses. The cross section of the main truss is usually divided into upper and lower parts, the upper section width is 4m, the height is about 4~4.5m (intersecting with the ellipsoid), the lower part is approximately trapezoidal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com