Quick installation method of coke oven guard plate and oven column

A technology for protecting plates and furnace columns, which is applied in the heating of coke ovens, coke ovens, and furnace foundations, etc., can solve the problems of poor mobility, low efficiency, and cumbersome implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

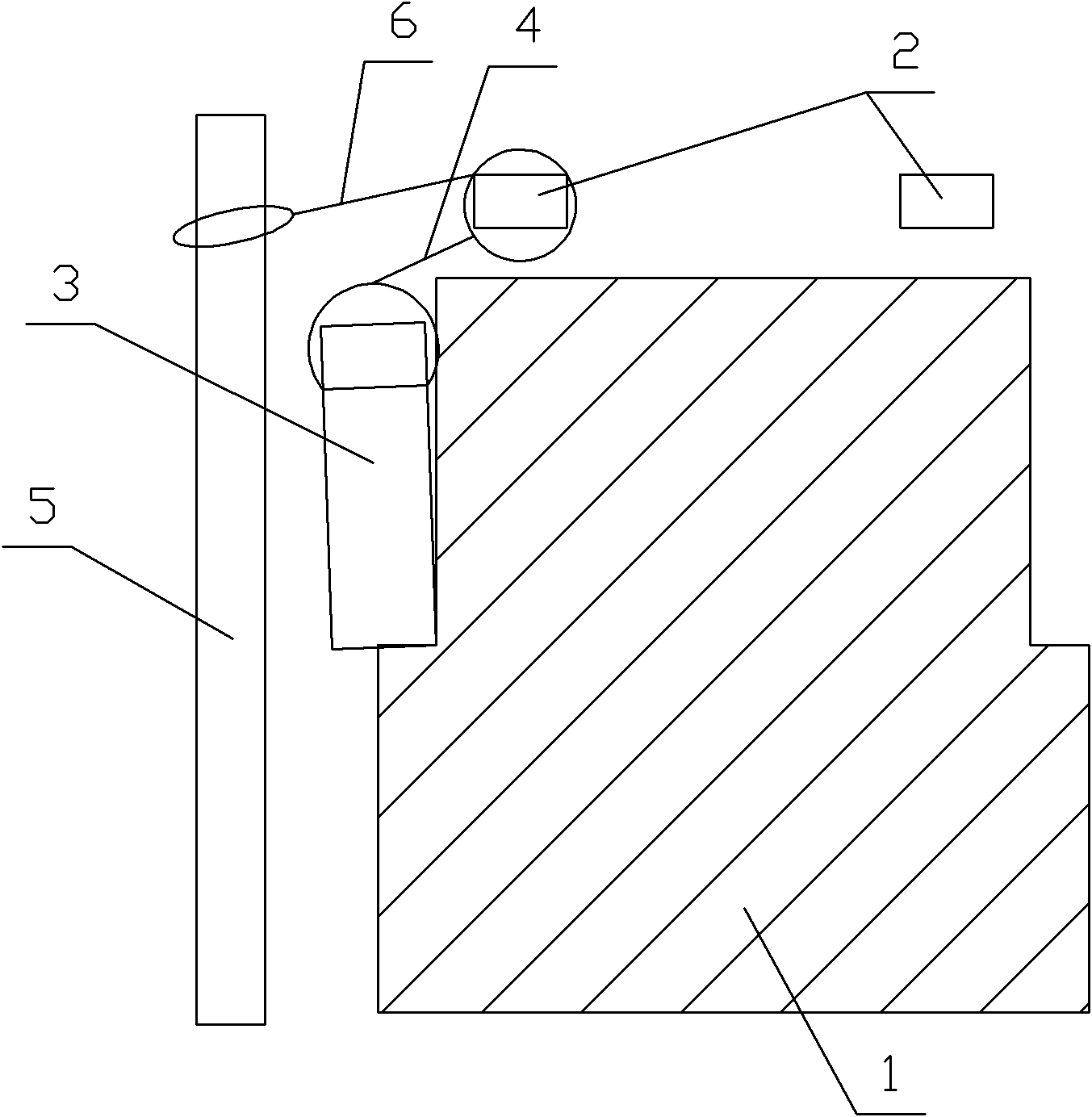

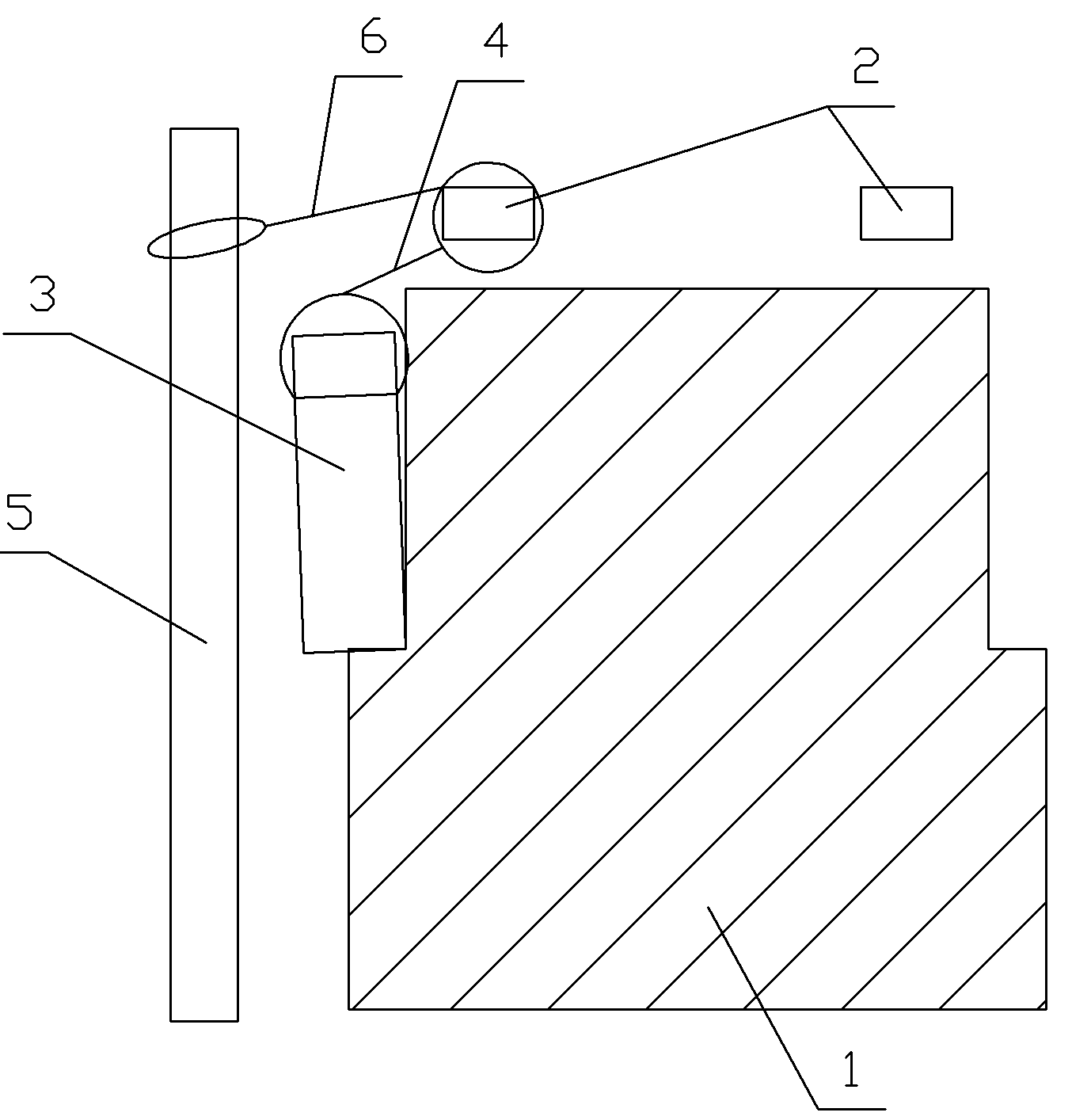

[0011] see figure 1 , a method for quick installation of a coke oven protection plate and a furnace pillar of the present invention: comprises the following steps: 1) after the coke oven body 1 is built by masonry, install the corresponding protection plate 3 and furnace pillar 5 on both sides of the coke on the top of the furnace Temporary fixing frames 2 are respectively installed at the positions; the temporary fixing frames 2 are preferably full-length angle steels, slotted on the furnace roof, and one side of the angle steels is placed in the groove so that the other side of the angle steels stretches out of the furnace roof, and the Drill connection holes on the edge of the angle steel on the top of the furnace; 2) after the protective ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com