Suspension type cast-in-place template curved bridge construction method

A suspended formwork technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problem that curved bridge decks cannot be constructed by hanging baskets or mobile formwork, and cannot bear the construction load of the overall cast-in-place bridge deck , Difficulty erecting the full hall support, etc., to achieve the effect of safe and reliable overall structure, easy dismantling and assembling operations, reducing construction safety risks and engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1 (three-hole curved bridge)

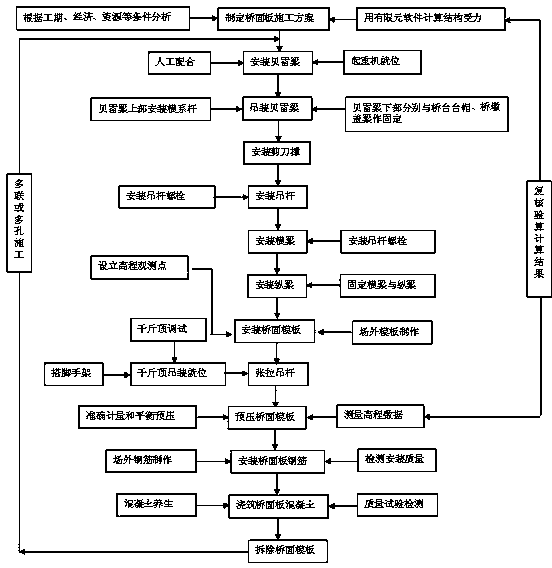

[0057] The operation steps of the suspended cast-in-place formwork curved bridge construction method are as follows:

[0058] ①Install Bailey Beam

[0059] a. Complete the construction of the half roadbed of the highway and the front and rear abutment caps of the other half of the bridge, and the front and rear pier caps between the front and rear abutment caps;

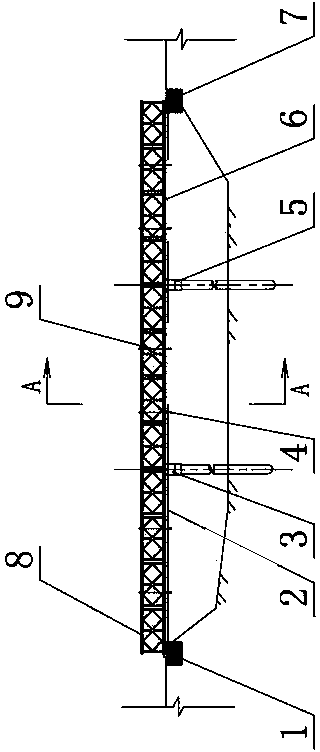

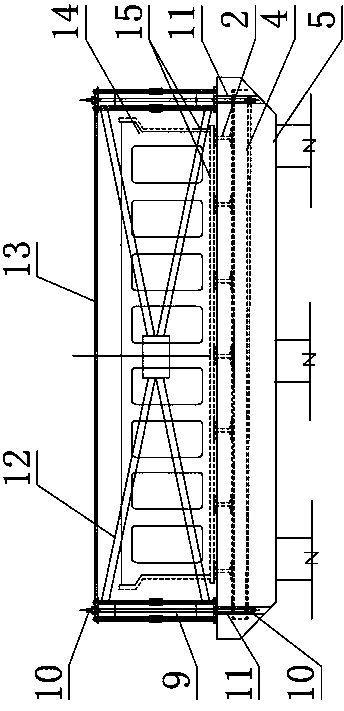

[0060] b. Assemble the two Bailey beams 8 on the half-width subgrade of the highway by means of a crane and manual cooperation. On the pier cover beam 3, its position is on the outside of the front abutment cap 1 and the front pier cover girder far away from the half-width subgrade of the highway. Fix the cover beam 3; then hoist the other one of the two Beile beams 8 to the front abutment platform cap 1 and the front pier cover beam 3 with a crane. The inner side of the abutment cap 1 and the front pier cover beam 3, the lower part of the Bailey beam is fixed by th...

Embodiment 2

[0084] Embodiment 2 (two hole straight bridge)

[0085] The operation steps of the suspended cast-in-place formwork curved bridge construction method are as follows:

[0086] ①Install Bailey Beam

[0087] a. Complete the construction of half of the highway subgrade and the front and rear abutment caps of the other half of the bridge, and the single pier cover beam between the front and rear abutment caps;

[0088] b. Assemble the two Bailey beams 8 on the half-width subgrade of the highway by means of a crane and manual cooperation, and first hoist one of the two Bailey beams to the front abutment cap 1 and the bridge pier with the crane in place On the cover beam, its position is on the outside of the front abutment cap 1 and the bridge pier cover beam far away from the half-width subgrade of the road. The lower part of the Bailey beam is respectively fixed with the front abutment cap 1 and the pier cover beam through fixed steel plates; The other of the two Bailey beams 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com