Horizontal deep hole stage slicing and caving mining method and stope for crushing thin ore body

A technology of caving mining and mining methods, applied in surface mining, underground mining, special mining, etc., can solve the problems of low ore recovery rate and cross-fall, and achieve the effect of reducing construction safety risks, high construction efficiency, and good project quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention:

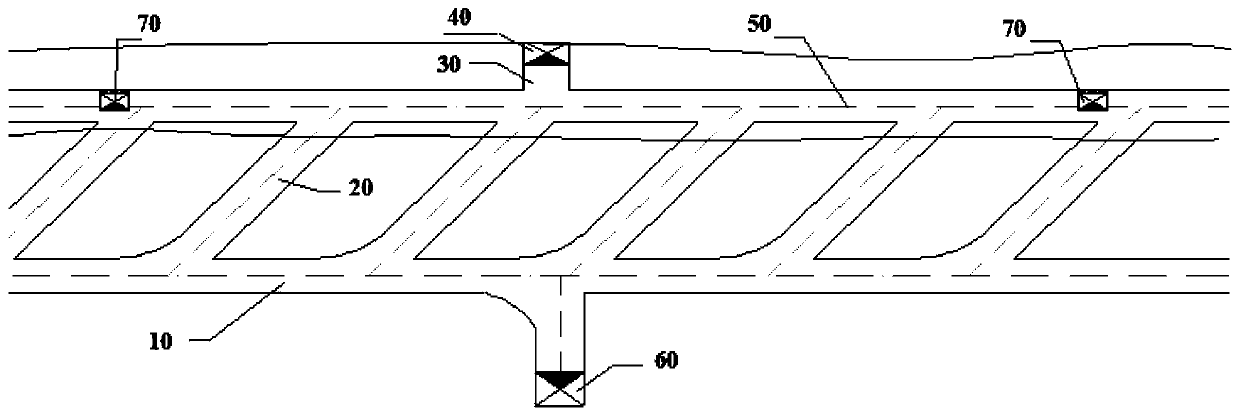

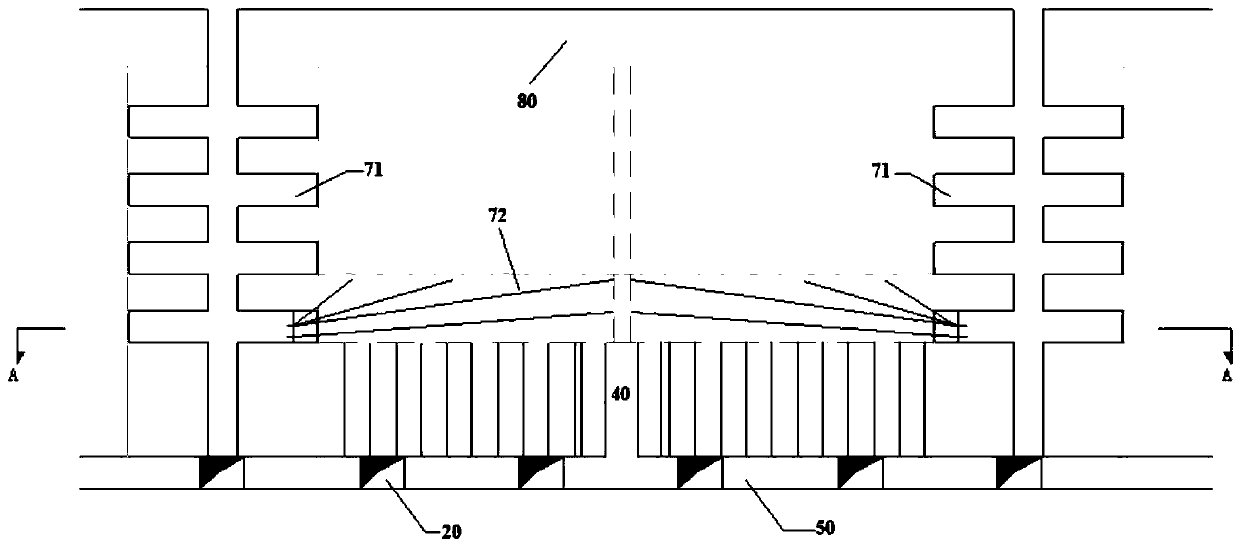

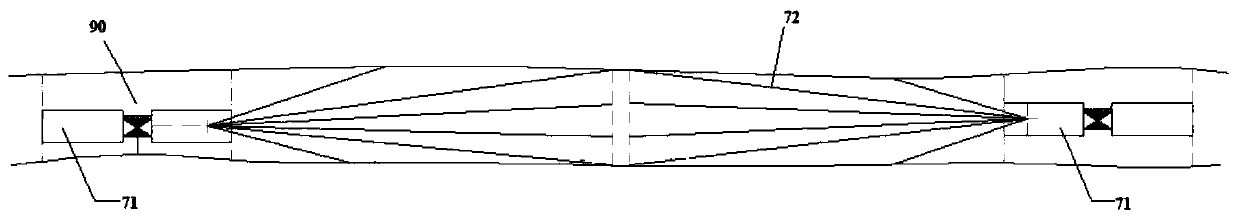

[0029] figure 1 Schematically shows the layout of the stope bottom structure (broken thin ore body). Such as figure 1 As shown, a stope is arranged along the strike of the ore body, and the bottom structure of the stope includes: an ore-receiving roadway (cutting ditch) 50 and a compensation space arranged along the bottom of the stope, an ore-exit connecting roadway 10, and a connected ore-exit roadway. A plurality of ore-out approaches 20 of the contact lane 10 and the mine lane 50. Wherein, the ore-exit connecting lane 10 and the ore-receiving lane 50 are arranged in parallel, the angle between the ore-exiting approach road 20 and the ore-exiting connecting lane 10 is 45 degrees, and the distance between two adjacent ore-exiting approaches 20 is 10m. Furth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com