A solid rocket motor charge emptying device

A technology of emptying device and solid rocket, which is applied to rocket engine devices, machines/engines, jet propulsion devices, etc., can solve the problems of unstable chemical properties of ammunition, low efficiency of drug dumping, different melting points, etc. Good adaptability and quick response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

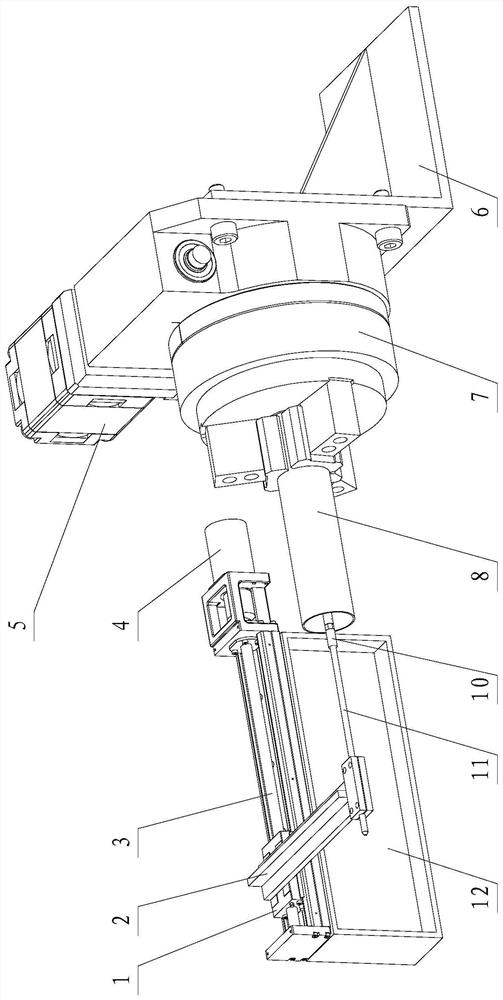

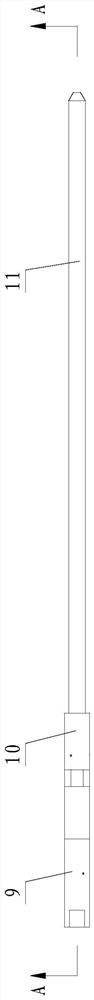

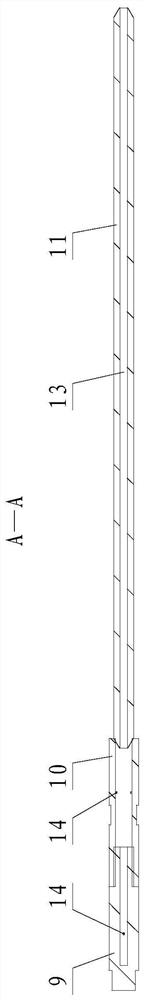

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] Such as figure 1 As shown, the present invention includes an ammunition charge positioning device and a water inlet cutter rod driving device, wherein the ammunition charge positioning device is located on one side of the water inlet cutter rod driving device; the ammunition charge positioning device includes a turntable motor 5 and a turntable motor seat 6 And the three-jaw chuck 7, the turntable motor 5 is installed on the turntable motor seat 6 by bolts, the output direction of the turntable motor 5 is perpendicular to the axial direction of the motor spindle; the output end of the turntable motor 5 is connected to one end of the three-jaw chuck 7 connected, the other end of the three-jaw chuck 7 is the clamping end, and the powder column 8 to be cleaned is clamped by the clamping end; one end of the three-jaw chuck 7 in this embodiment is fixedly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com