Pouring machine and pouring method for concrete of road shoulder on high-speed railroad bed section

A technology of high-speed railway and pouring method, which is applied in the direction of infrastructure engineering, construction, etc., can solve the problems of difficult control of slope, difficulty in operation and standing, and low construction efficiency, so as to improve internal quality and appearance quality, reduce construction safety risks, and improve The effect of construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

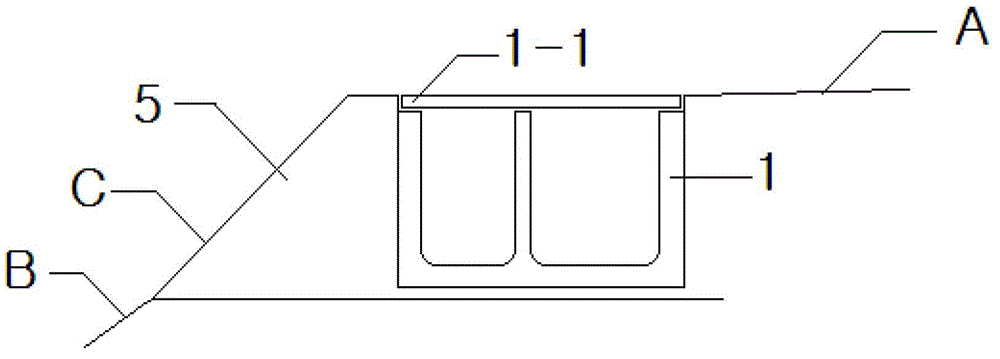

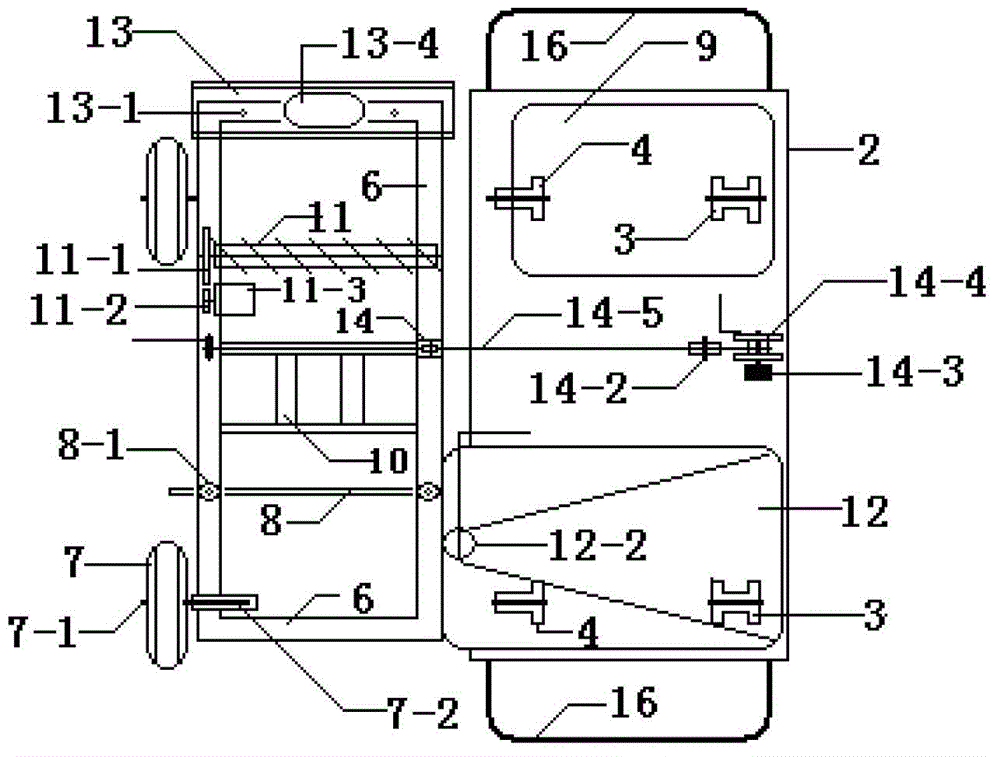

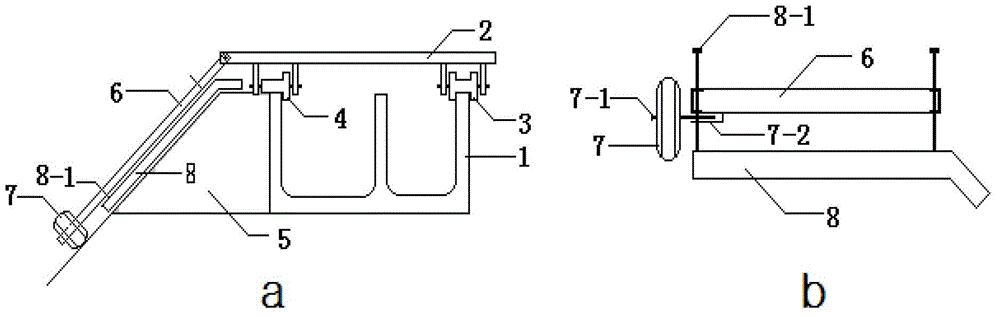

[0028] Such as Figure 2~Figure 6 As shown, a high-speed railway subgrade section road shoulder concrete pouring machine includes a rectangular frame 2, a hopper is arranged on the front part of the frame; The generator 13-4 runs. Respectively arrange a pair of walking wheels before and after the frame below and just place on the walking track 15 on the roadbed cable trough. A work frame 6 is hinged on the left or right side of the frame (the present embodiment is the left side). The paving scraper 8, the vibrating operation pedal 10, the leveling coiler 11, and the plastering panel 13 are sequentially arranged on the work frame from the front to the rear, and the concrete can be paved and scraped, vibrated, leveled, Wiping equal work.

[0029] The pouring machine in this embodiment is also provided with a working frame retractable device: including a low-position fixed pulley 14-2 on the frame 2, a lifting column 14-3 and a ratchet-type hand-operated lifting windlass 14-4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com