High pier sliding and turning integrated construction formwork system

A formwork and high pier technology, which is applied in the field of high pier sliding and overturning integrated construction formwork system, can solve problems such as easy slurry leakage, achieve the effect of eliminating friction, solving the difficulty of high pier health maintenance, and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

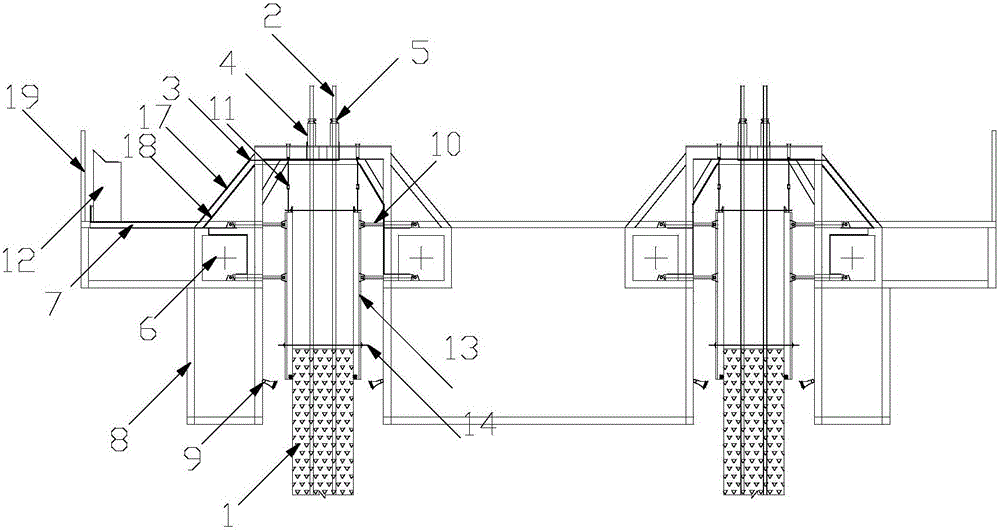

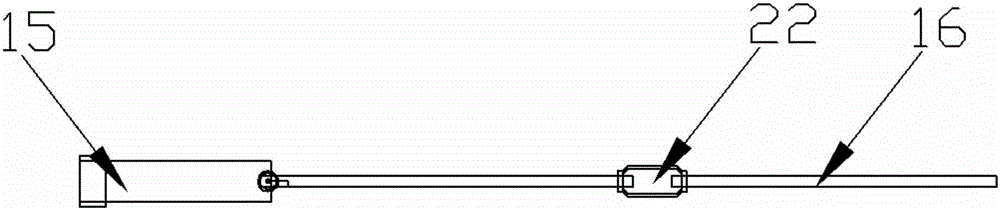

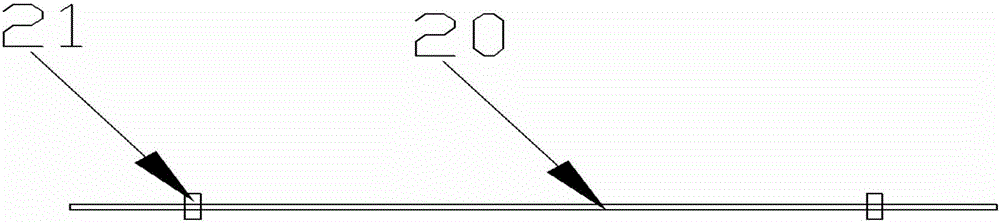

[0027] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 As shown, a slip-and-turn integrated formwork system for high pier construction includes a steel pipe upright 2 pre-embedded in the concrete 1, the steel pipe upright 2 passes through the beam part of the bracket 3, and one end of the hydraulic jack 4 passes through the positioning The snap ring 5 is fixed on the steel pipe pole 2, and the other end is connected with the beam part of the bracket 3, the enclosure 6 is fixed on the side surface of the bracket, the working platform 7 is laid above the enclosure 6, and the bottom of the enclosure 6 is installed Decorate the hanging basket 8, the automatic spraying maintenance device 9 is installed on the decorating hanging basket 8, the module is located in the bracket, the side of the module is connected with the enclosure through the hydraulic bar 10 which can adjust the position of the module horizontally, the top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com