Method for treating light section tunnel collapse

A small-section, tunnel technology, applied in tunnels, tunnel linings, earthwork drilling, etc., can solve problems such as unsmooth implementation of solutions, secondary landslides, and limited grouting consolidation thickness of landslides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing.

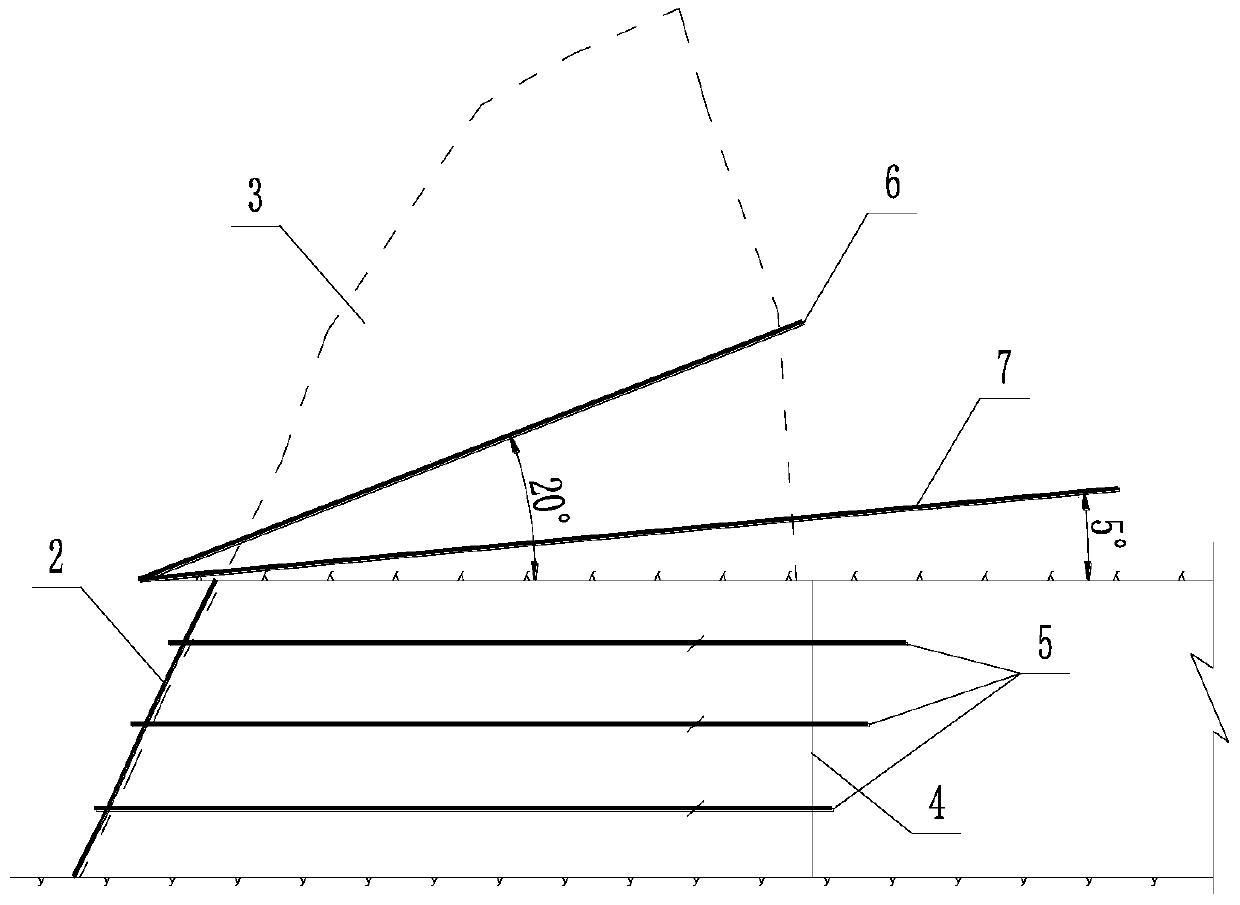

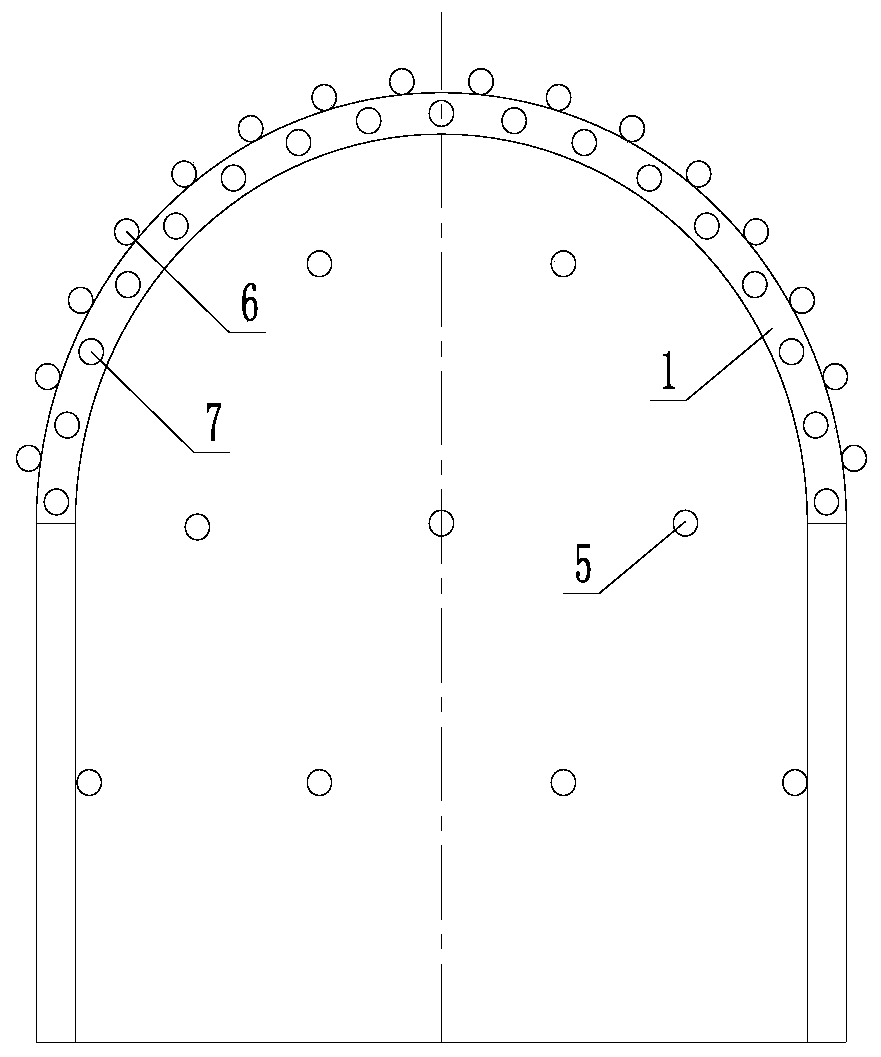

[0034] refer to figure 1 with figure 2 As shown, in the weak and broken surrounding rock tunnel section of a small-section tunnel, the landslide body 3 blocks the original tunnel face 4 and forms a new tunnel face 2. The method for dealing with the collapse of a small-section tunnel in the present invention includes the following steps:

[0035] S1. Install support frame 1 to reinforce the tunnel

[0036] The support frame 1 is used to reinforce the tunnel near the collapsed position and provide a safe construction position. At the position where construction conditions are available behind the slag body of the new tunnel face 2, first remove the scum on the footing, and then carry out the support frame 1 support construction. Support frame 1 steel support frame, the arch feet of the steel support frame have a certain depth of embedding, and fall on a firm foundation. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com