Changeable retractor device for railroad bridge

A telescopic device and bridge technology, applied in bridges, bridge construction, bridge parts, etc., can solve the problems of damaged waterproof belts, difficult installation, inability to replace, etc., and achieve large clamping force reserve, protection performance guarantee, and good waterproof performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the drawings and embodiments.

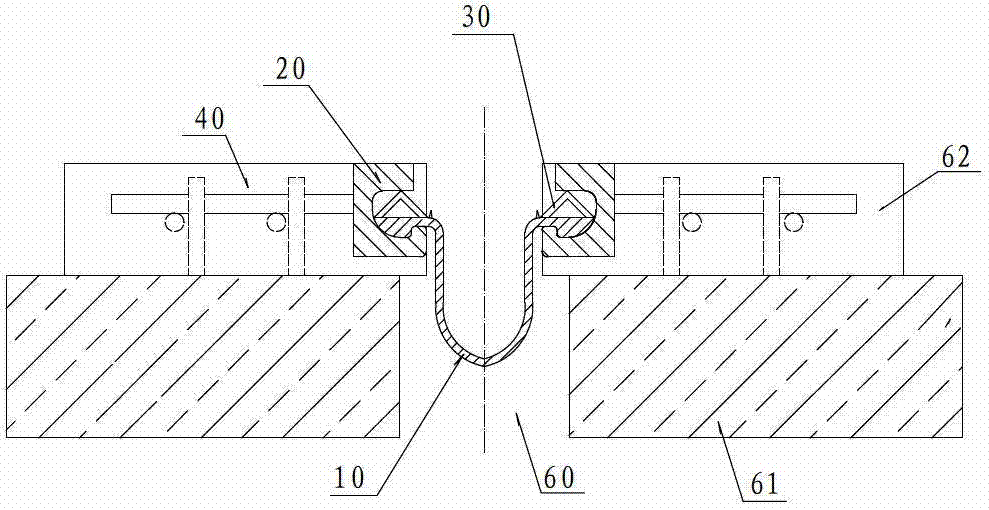

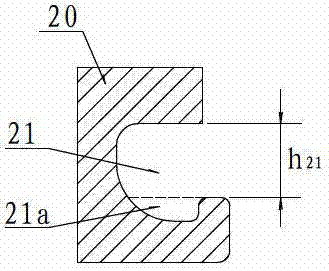

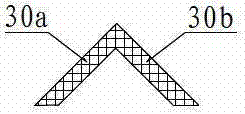

[0024] Reference figure 1 , The replaceable telescopic device of the railway bridge of the present invention includes a pair of connecting strips 20 fixed on the two side walls of the expansion joint 60 by an anchoring member 40, and a waterproof belt 10 connected with the connecting strips 20 on both sides. 20 has an anchor groove 21 extending in the full length direction. Reference figure 1 , figure 2 with Figure 4 The two sides of the waterproof belt 10 have downwardly protruding anchor fixing bosses 11, and the cross-sectional shape of the anchor fixing boss 11 matches the cross-sectional shape of the groove 21 a under the anchor groove 21. The two sides of the waterproof tape 10 are pulled into the anchor groove 21 from the longitudinal end of the connecting strip 20, and the locking strip 30 is pressed into the space between the upper surface of the waterproof ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com