High-precision extinction ratio test method and system

A test method and technology of extinction ratio, applied in the field of optical communication, can solve the problem of test accuracy, poor working stability, large fluctuation of the transconductance value of PIN photodiode responsivity, and inability to measure the true value of the extinction ratio of the optical module under test, etc. problem, to achieve the effect of high-precision measurement and stable temperature characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to make the purpose, technical solution and advantages of the present application clearer, the present application will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0058] For simplicity, some technical features known to those skilled in the art are omitted from the following description.

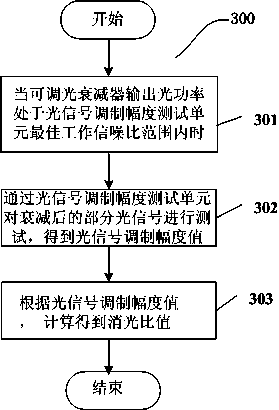

[0059] refer to image 3 , image 3 Shown is a flowchart of an embodiment 300 of the high-precision extinction ratio testing method of the present invention. Method 300 includes steps 301 to 303 .

[0060] In step 301, the optical signal is attenuated by the adjustable optical attenuator until its output optical power is within the optimal working signal-to-noise ratio range of the optical signal modulation amplitude test unit; refer to Figure 4 , Figure 4 It is a flow chart of an embodiment of a method 400 for attenuating part of the optical signal to the range of the best working signal-to-noise ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com