Self-anchoring type mounting method of suspension bridge

A self-anchored suspension bridge and installation method technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems affecting the speed of the installation and construction of steel box girder, the threat to the safety of supports, and the rapid rise and fall of floods, so as to speed up the construction. Speed, reduce construction safety risks, and reduce the effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0031] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0032] A method for installing a self-anchored suspension bridge, comprising the steps of:

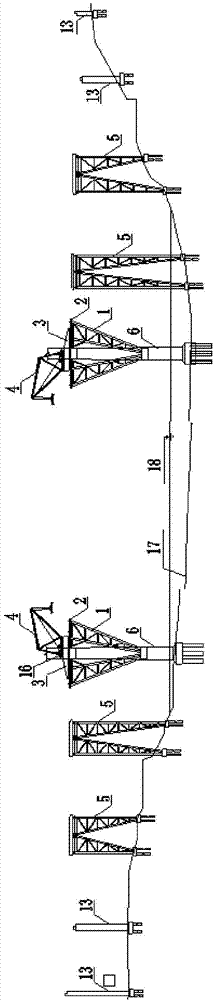

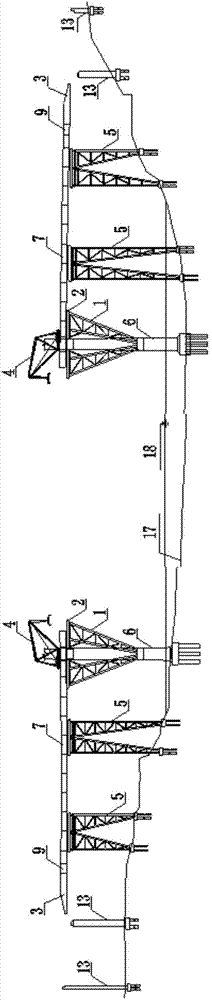

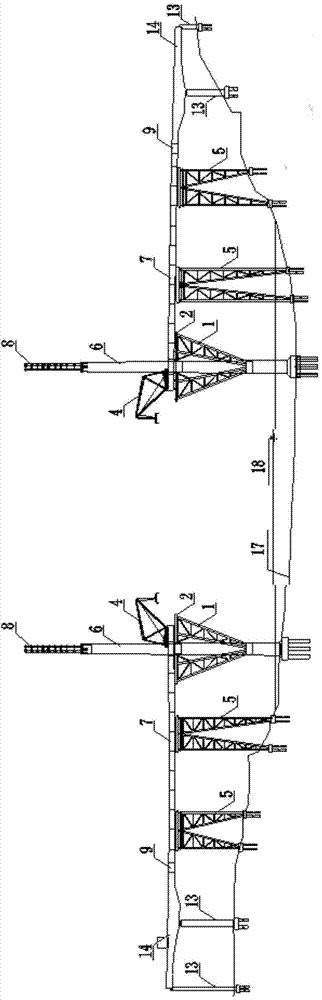

[0033] ① if figure 1 As shown, construction main tower pier 6 and main bridge side pier 13;

[0034] ② Assemble the supporting bracket 1 of the steel box girder on the main tower pier 6, and install the steel guide beam 3 on the slideway beam 2 at the top of the supporting bracket 1;

[0035] It should be noted that the supporting bracket 1 here can also serve as a side-span steel box girder pushing construction platform, which has a reliable structure and is easy to construct.

[0036] ③ Assemble the girder crane 4 on the crane base 16 on the slideway beam 2, and assemble the side-span steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com