Bridge hollow-pier cantilever formwork and construction method thereof

A hollow pier and formwork technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of formwork debugging, difficulty in testing concrete decoration, cumbersome bolt connection and tightening process, etc. Simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

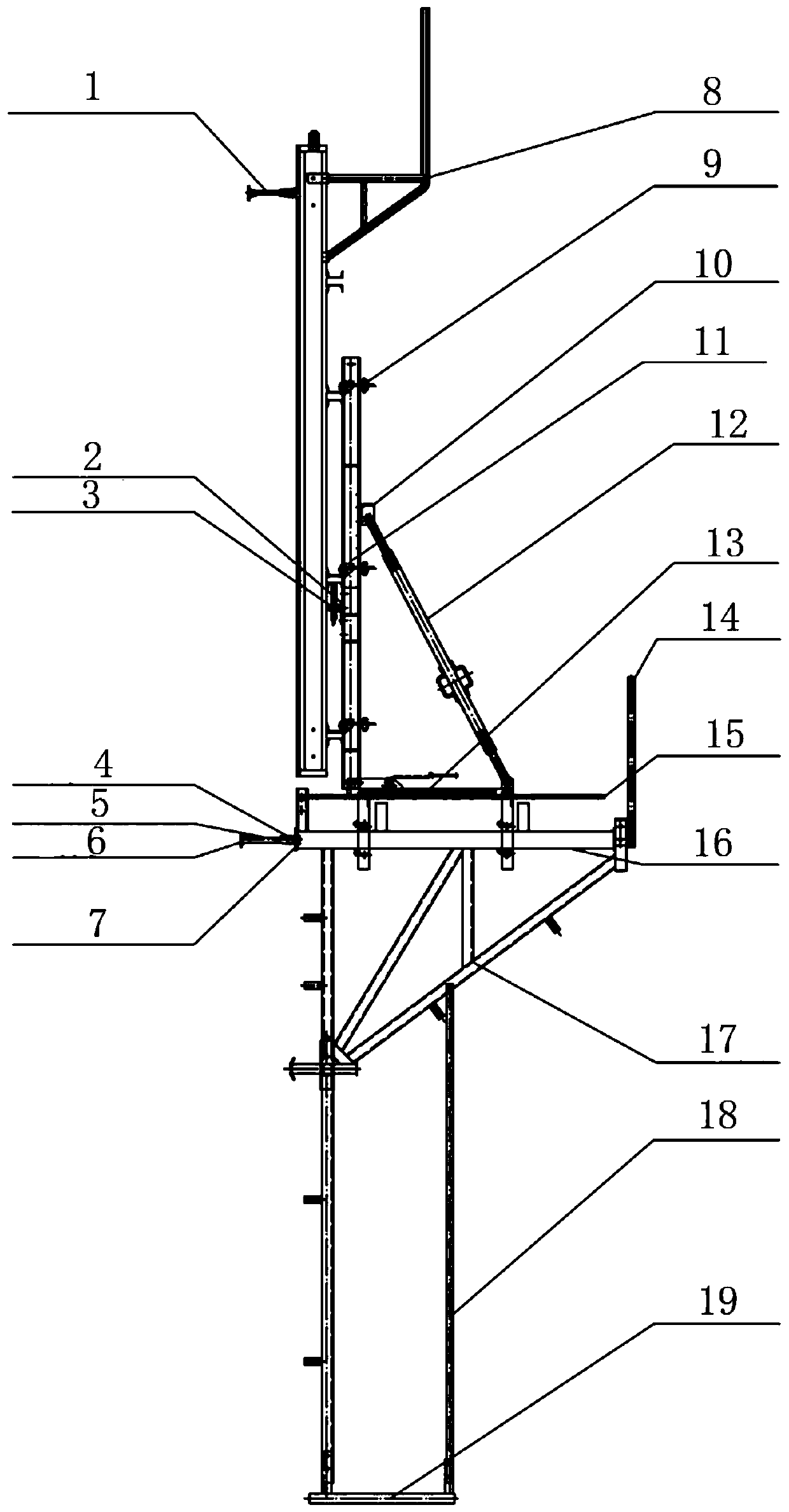

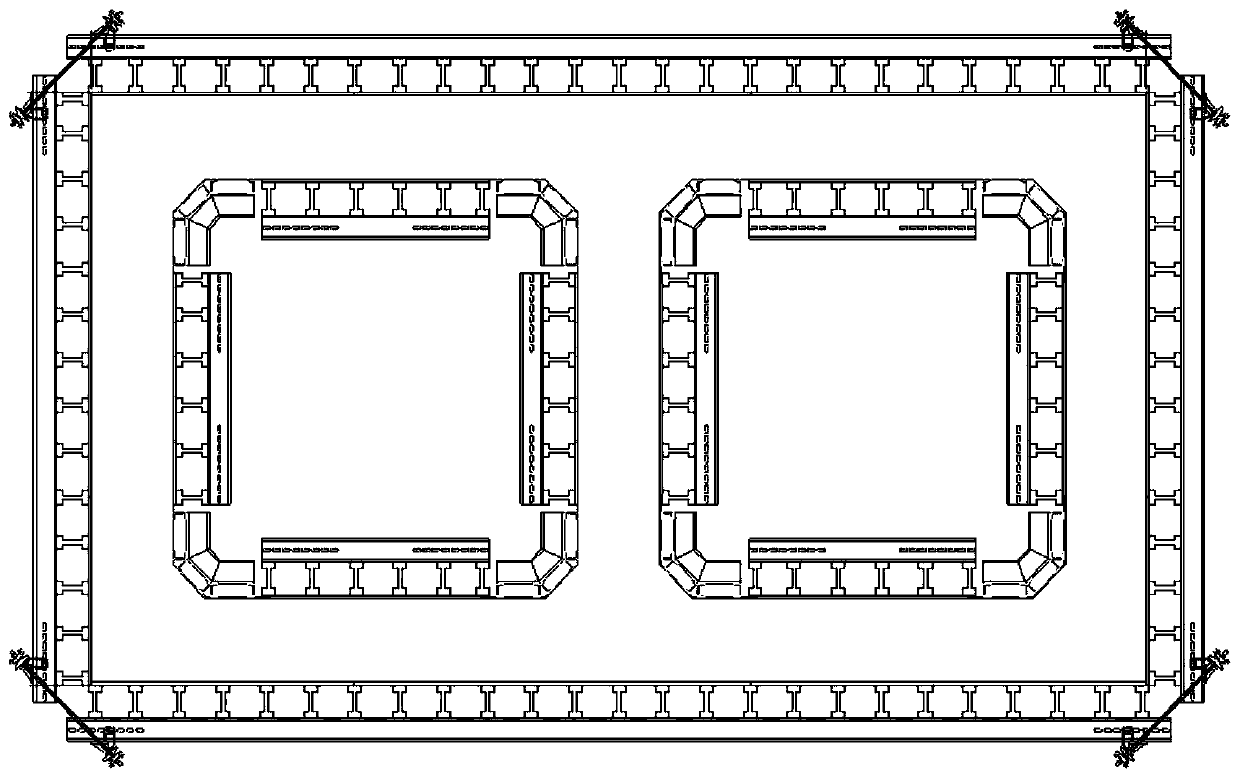

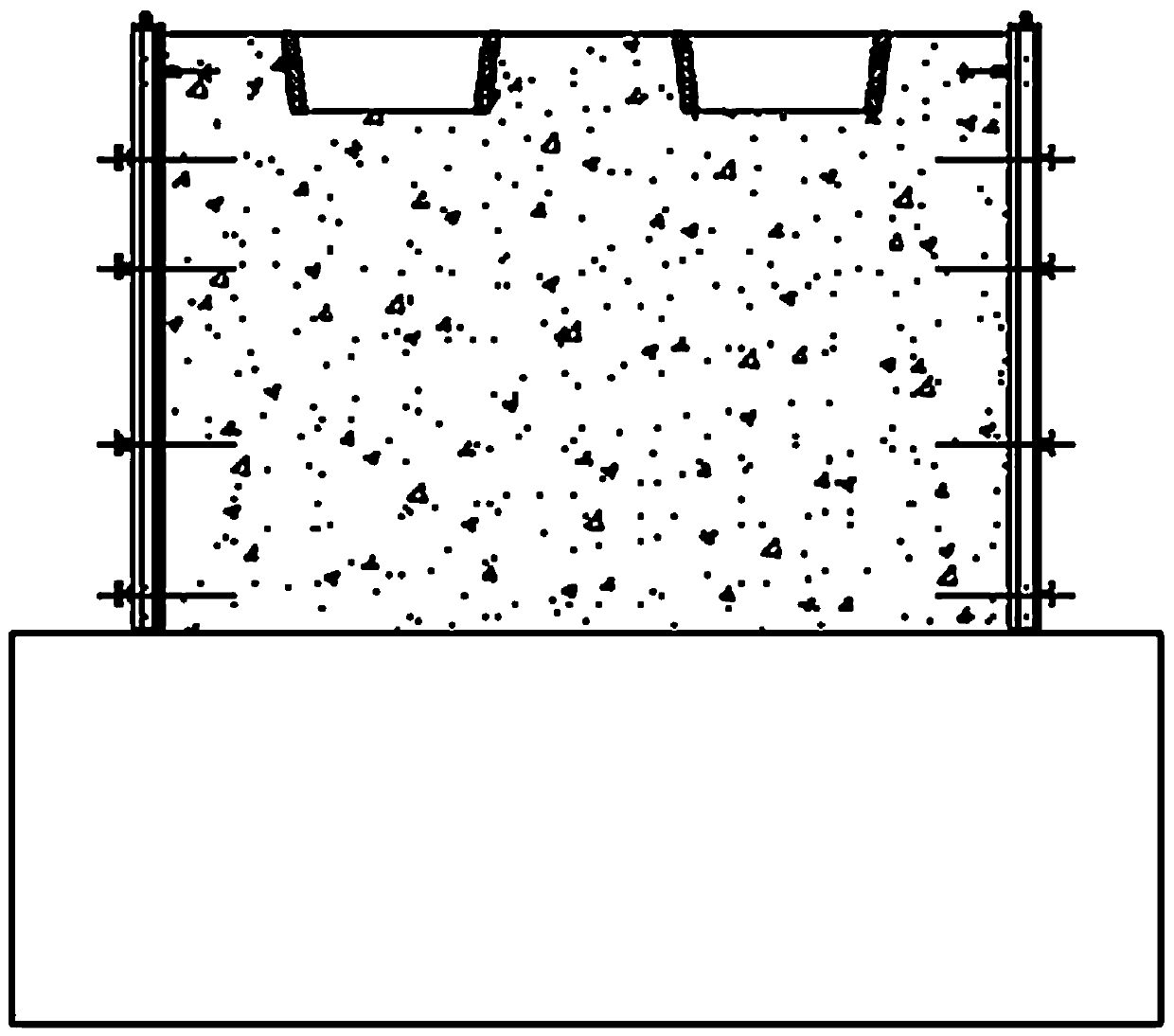

[0038] see figure 1 , in this embodiment, a cantilever formwork for a bridge hollow pier, including an embedded system 1, an adjusting screw 2, an adjusting seat 3, a climbing cone 4, a high-strength screw 5, an embedded plate 6, a force bolt 7, and a wooden beam pick Frame 8, back corrugated fastener 9, diagonal brace support 10, main back corrugated 11, diagonal brace 12, rear moving trolley 13, platform pole 14, rear moving rack 15, tripod beam 16, tripod 17, hanging platform stand Rod 18 and suspended platform beam 19.

[0039] The bottom of the tripod 17 is connected to the suspension platform pole 18, and the bottom of the suspension platform pole 18 is connected to the suspension platform crossbeam 19; Embedded plate 6, high-strength screw 5 is connected to embedded plate 6, the diameter of high-strength screw 5 is 20mm, and high-strength screw 5 is provided with climbing cone 4, the thread diameter of the large end of climbing cone 4 is 30mm, and the diameter of small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com